China's Prime Minister Highlights Stepper Motor Technology in Recent Address

By:Admin

With a history of over 20 years, the company has emerged as a top producer of stepper motors, serving a wide range of industries including robotics, 3D printing, CNC machining, and automation. The company's commitment to research and development has resulted in a diverse product line that meets the evolving demands of modern industries.

In his address, the Prime Minister applauded the company for its contribution to China's industrial sector, highlighting its role in driving innovation and pushing the boundaries of technological advancement. He emphasized the importance of such companies in realizing China's vision of becoming a global leader in advanced manufacturing.

The company's success story is a testament to China's commitment to fostering a favorable environment for industrial growth and innovation. Through strategic investment in research and development, as well as infrastructure, China has positioned itself as a hub for cutting-edge technology and manufacturing capabilities. The company's achievements reflect the broader progress that China has made in becoming a formidable force in the global industrial landscape.

The company's dedication to quality and excellence has earned it a strong reputation in the international market. With a strong focus on precision engineering and reliability, the company has become a preferred supplier for companies around the world. Its products are renowned for their performance and durability, making them an ideal choice for a wide range of industrial applications.

The Prime Minister's praise for the company underscores its significance in China's economic development. As China continues to prioritize innovation and technological advancement, companies like this stepper motor manufacturer will play a pivotal role in driving the country's industrial progress. Their ability to deliver high-quality products that meet the demands of the global market is a testament to China's growing prowess in advanced manufacturing.

Looking ahead, the company is poised to capitalize on the opportunities presented by China's ambitious industrial plans. With a strong focus on expanding its global footprint and leveraging its technological expertise, the company is well-positioned to contribute to China's vision of becoming a global manufacturing powerhouse. Its innovative products and commitment to excellence will continue to set the standard for the industry, solidifying China's position as a leader in advanced manufacturing.

In conclusion, the success of this prominent stepper motor manufacturer is a reflection of China's remarkable progress in the industrial sector. With the support of the government and a commitment to innovation, the company has established itself as a global leader in the field of advanced manufacturing. Its achievements serve as a testament to China's growing influence in the global industrial landscape and its potential to shape the future of manufacturing.

Company News & Blog

High-Performance Microstepper Motor: The Latest Breakthrough in Motor Technology

ODM Microstepper MotorIn today's rapidly evolving technological landscape, the demand for compact and precise motor solutions has never been higher. That's where ODM Microstepper Motor comes in. This innovative company has been at the forefront of developing advanced microstepper motor technology, offering unparalleled precision and reliability in a small form factor. With a commitment to quality and an unwavering dedication to innovation, ODM Microstepper Motor has established itself as a leading provider of microstepper motor solutions for a wide range of industries.The company, founded in 2003, has a long history of pushing the boundaries of what is possible in the field of microstepper motor technology. Their team of highly skilled engineers and researchers are constantly striving to develop new and improved motor solutions that meet the evolving needs of their customers. By focusing on precision engineering and advanced manufacturing processes, ODM Microstepper Motor has been able to consistently deliver cutting-edge motor solutions that exceed customer expectations.One of the key strengths of ODM Microstepper Motor is their ability to customize their motor solutions to fit the unique requirements of their clients. Whether it's a specific torque range, speed, or form factor, the company's engineering team works closely with their customers to develop bespoke motor solutions that are perfectly tailored to their needs. This level of customization sets ODM Microstepper Motor apart from other motor manufacturers and has earned them a strong reputation for delivering high-quality, reliable motor solutions.ODM Microstepper Motor's products are utilized in a diverse range of applications, including robotics, medical devices, aerospace, and more. Their microstepper motors are known for their precision, quiet operation, and long-term reliability, making them the ideal choice for critical applications where performance is paramount. With a focus on continuous improvement and innovation, ODM Microstepper Motor is constantly working to enhance their products and develop new solutions that push the boundaries of what is possible in microstepper motor technology.In addition to their innovative products, ODM Microstepper Motor also prides itself on providing exceptional customer service and support. The company's team of experts is dedicated to helping their clients find the perfect motor solution for their needs and ensuring that they have the support they need to integrate the motors into their systems seamlessly. This commitment to customer satisfaction has been a driving force behind the company's success and has helped them build long-lasting relationships with their clients.Looking ahead, ODM Microstepper Motor is poised to continue leading the way in the field of microstepper motor technology. With a focus on innovation, quality, and customer satisfaction, the company is well-positioned to meet the evolving needs of their clients and the industry as a whole. As technology continues to advance, ODM Microstepper Motor will undoubtedly play a crucial role in shaping the future of microstepper motor technology. Their ongoing dedication to excellence and unwavering commitment to pushing the boundaries of what is possible in motor solutions make them a company to watch in the years to come.

Small Gear Motors Gain Popularity in Industrial Applications: Report

OEM Mini Gear Motor: Powering Industries WorldwideMini Gear Motors are indispensable components in various industries ranging from automation, healthcare, transportation, and robotics. They come in different sizes, shapes, and torque, but what they all have in common is their ability to deliver reliable and consistent performance. One brand that shines in this category is the OEM Mini Gear Motor.But what is an OEM Mini Gear Motor, and why is it a popular option for many industrial applications? In this article, we will discuss the fundamentals of these gear motors and the advantages of choosing OEM Mini Gear Motor over other brands in the market.Understanding OEM Mini Gear MotorOEM Mini Gear Motor, which we will refer to as OMG moving forward, is a prominent supplier of high-quality mini gear motors. The company specializes in the production of brushed DC and brushless DC gear motors. It was established in 2001 and has since grown into a multidisciplinary firm with offices in various countries worldwide.OMG offers a wide range of mini gear motors with different power and torque ratings. The motors come in three types: planetary, spur, and worm gearboxes. Planetary gearboxes offer the most torque and are ideal for applications that require high precision and control. Spur gearboxes have less torque but are quieter and more efficient. Worm gearboxes offer the least torque but are compact and lightweight, making them suitable for small applications.OMG's mini gear motors are made of high-quality materials that ensure durability and longevity. The motors' housings are made of aluminum or stainless steel, with hardened steel or sintered bronze gears. The bearings are made of high-quality materials, such as ceramic or stainless steel, that can withstand high radial and axial loads.Advantages of Choosing OEM Mini Gear MotorOMG's mini gear motors have several features that set them apart from other brands in the market. Here are some of the advantages of choosing OMG's mini gear motors for your industrial applications:1. High QualityOMG's mini gear motors are made of high-quality materials, ensuring that they are durable and reliable. The motors go through strict quality control measures to ensure that they meet the specifications of the customers and international standards.2. Energy EfficiencyOMG's mini gear motors have a high power-to-size ratio, making them energy-efficient. They have low power consumption, allowing for longer life battery life and reduced environmental impact.3. CustomizableOMG can customize mini gear motors to meet the specific requirements of the customer's application. They offer a range of options, including special motors, gear ratios, and shaft configurations.4. Low NoiseOMG's mini gear motors have a low noise level, making them ideal for use in applications where noise is a concern. The motors are also vibration-free, ensuring that they provide smooth, precise, and consistent performance.5. Cost-effectiveOMG's mini gear motors are competitively priced, making them an affordable option for many industrial applications. They are also easy to install and maintain, reducing the overall cost of ownership.Applications of OEM Mini Gear MotorOMG's mini gear motors are widely used in various industries. Here are some examples of applications that use OMG's mini gear motors:1. RoboticsMini gear motors are used in various types of robotics, such as industrial robots, drones, and humanoid robots. The motors provide precise and consistent motion control, making them ideal for use in applications that require high precision.2. HealthcareMini gear motors are used in various types of medical equipment, such as surgical robots, infusion pumps, and diagnostic equipment. The motors provide accurate and precise control, ensuring that the equipment functions as intended.3. TransportationMini gear motors are used in various types of transportation, such as electric bikes, scooters, and wheelchairs. The motors provide efficient and reliable power, ensuring that the vehicle can travel long distances without frequent recharging.4. AutomationMini gear motors are used in various types of automation, such as conveyor belts, packaging machines, and assembly lines. The motors provide smooth and consistent motion, ensuring that the automation process is efficient and error-free.ConclusionOEM Mini Gear Motor is a leading supplier of high-quality mini gear motors. The company offers a wide range of customizable options, making them ideal for use in various industrial applications. The motors are energy-efficient, low noise, and cost-effective, ensuring that they provide optimal value for money. With their durable and reliable performance, OMG's mini gear motors power industries worldwide.

High-quality Mini Stepper Motors for ODM Applications

Mini stepper motors are becoming increasingly popular in the world of technology and engineering. These small but powerful motors are used in a wide range of applications, from robotics and automation to consumer electronics and medical devices. One company that is leading the way in the development and production of mini stepper motors is ODM (name removed for confidentiality), a global leader in the field of motion control and automation.ODM has been a key player in the industry for over 30 years, and their expertise in the design and manufacture of high-quality motion control components is second to none. The company's mini stepper motors are renowned for their precision, reliability, and versatility, making them the go-to choice for engineers and designers across the globe.One of the key features of ODM's mini stepper motors is their compact size. These motors are small and lightweight, making them ideal for applications where space is at a premium. Despite their small size, ODM's mini stepper motors deliver impressive performance, with high torque and smooth, precise motion control. This makes them suitable for a wide range of applications, from small-scale robotics and 3D printers to medical devices and consumer electronics.In addition to their compact size and high performance, ODM's mini stepper motors are also known for their energy efficiency. These motors are designed to minimize power consumption while maximizing output, making them an environmentally friendly choice for companies and organizations working to reduce their carbon footprint.Another key advantage of ODM's mini stepper motors is their durability. These motors are built to last, with rugged construction and high-quality materials that ensure they can withstand the demands of even the most challenging environments. This makes them the perfect choice for applications where reliability is paramount, such as industrial automation and aerospace.ODM's commitment to innovation and continuous improvement is another factor that sets their mini stepper motors apart from the competition. The company invests heavily in research and development, constantly pushing the boundaries of what is possible in the world of motion control. This commitment to innovation means that ODM's mini stepper motors are always at the cutting edge of technology, incorporating the latest advancements in materials, design, and manufacturing techniques.As a global leader in motion control and automation, ODM is dedicated to providing its customers with the highest quality products and exceptional service. The company has a team of highly skilled engineers and technical experts who work closely with customers to understand their specific needs and develop customized solutions that meet and exceed their expectations.In addition to their technical expertise, ODM also prides itself on its commitment to sustainability and corporate responsibility. The company is dedicated to minimizing its environmental impact and operates in accordance with the highest ethical and environmental standards. This commitment to sustainability extends to the design and manufacture of ODM's mini stepper motors, which are designed to be as energy-efficient and environmentally friendly as possible.Overall, ODM's mini stepper motors are a testament to the company's dedication to excellence, innovation, and customer satisfaction. With their compact size, high performance, energy efficiency, and durability, these motors are the perfect choice for a wide range of applications in industries such as robotics, automation, consumer electronics, and medical devices. Whether it's a small-scale hobby project or a large-scale industrial application, ODM's mini stepper motors are the ideal solution for engineers and designers looking for precision motion control in a compact package.

Learn about the benefits and uses of a 5-pin stepper motor

{Company Name} Introduces Advanced New 5-Pin Stepper Motor Technology{City, Date} - {Company Name}, a leader in innovative motor technology, has officially introduced their latest advancement in stepper motor technology. The new 5-pin stepper motor has been specially designed to meet the increasing demand for high-performance, precision motors in a wide range of applications.This new stepper motor is set to revolutionize the industry with its advanced features and capabilities. With 5 pins instead of the traditional 4 pins, this motor offers increased control and precision, making it ideal for complex applications that require precise positioning and high torque. The motor also boasts improved reliability and efficiency, making it a cost-effective solution for businesses seeking to enhance their operational processes.The 5-pin stepper motor is the result of years of research and development by {Company Name}'s team of expert engineers and technicians. The motor features a unique design that optimizes performance while also minimizing energy consumption. This makes it an environmentally-friendly choice for businesses looking to reduce their carbon footprint and energy costs.{Company Name} has a long-standing reputation for producing high-quality, reliable motors, and the 5-pin stepper motor is no exception. Customers can expect the same level of excellence and durability that the company is known for, ensuring that their investment in this new technology will yield long-term benefits.In addition to its technical capabilities, the 5-pin stepper motor is also designed with user-friendliness in mind. Its compact size and easy installation process make it accessible to businesses of all sizes, from small startups to large-scale manufacturing operations. {Company Name} understands the importance of ease of use, and has designed this motor to be as straightforward and intuitive as possible for its users.The applications for the 5-pin stepper motor are vast and diverse. From robotics and automation to 3D printing and CNC machining, this motor is poised to make a significant impact across a wide range of industries. Its versatility and adaptability make it an attractive option for businesses looking to upgrade their existing equipment or implement new technology into their operations.{Company Name} is excited to bring this innovative new technology to the market and is confident that it will be well-received by industries seeking reliable, high-performance motors. The company's commitment to excellence and continuous improvement is evident in the development of the 5-pin stepper motor, and they are proud to offer this cutting-edge technology to their valued customers.As the demand for precision motors continues to grow, {Company Name} is dedicated to staying ahead of the curve in motor technology. The introduction of the 5-pin stepper motor demonstrates their ongoing dedication to innovation and their commitment to providing their customers with the best possible solutions for their needs.In conclusion, the introduction of the 5-pin stepper motor is a significant milestone for {Company Name} and a promising development for industries seeking advanced motor technology. With its unparalleled performance, efficiency, and ease of use, this motor is set to become a game-changer in the world of precision motors. Businesses looking to enhance their operations and stay ahead of the competition can trust {Company Name} to deliver the highest quality motors, backed by exceptional service and support.

Top Wholesale Supplier of Stepper Motor Angle at Competitive Prices

Wholesale stepper motor angle distributor recently revealed its latest product offering, providing a comprehensive range of stepper motors suitable for various industrial applications. The company, known for its high-quality products and reliable service, aims to meet the growing demand for precision motors within the manufacturing sector.Stepper motors are widely used in automated machinery, robotics, 3D printing, and other applications requiring precise control of movement. These motors are known for their ability to divide a full rotation into a large number of steps, making them ideal for applications that require precise positioning and controlled speed. With the increasing automation of manufacturing processes, the demand for stepper motors has been steadily rising, driving the need for reliable suppliers who can provide high-quality products at competitive prices.The wholesale distributor offers stepper motors with a wide range of angles, allowing customers to choose the most suitable option for their specific application. With a focus on precision and performance, the motors are designed to meet the highest industry standards, ensuring smooth and reliable operation in a variety of industrial settings. The company's extensive product range includes various torque and speed options, accommodating the diverse needs of its customers.In addition to its product offerings, the company takes pride in its commitment to customer service and technical support. With a team of experienced professionals, the distributor offers personalized assistance to help customers choose the right stepper motor for their applications. Whether it's selecting the appropriate angle, torque, or speed, the company's experts are dedicated to ensuring that customers receive the best possible solution for their needs.Furthermore, the wholesale distributor places a strong emphasis on quality control and assurance. All stepper motors undergo rigorous testing to ensure their performance and reliability, giving customers the peace of mind that they are investing in a high-quality product that will meet their needs for years to come. With a reputation for excellence in the industry, the company has established itself as a trusted source for stepper motors among manufacturing professionals and businesses.As the demand for precision motors continues to grow, the wholesale distributor remains committed to staying ahead of the curve by continuously expanding its product range and improving its services. By leveraging its expertise and industry knowledge, the company aims to be at the forefront of supplying high-quality stepper motors to meet the evolving needs of the manufacturing sector. With a focus on innovation and customer satisfaction, the distributor is poised to remain a leading player in the stepper motor market for years to come.In conclusion, the wholesale stepper motor angle distributor stands as a reliable source for high-quality stepper motors designed for precision and performance. With a diverse product range, personalized customer service, and a commitment to quality, the company has positioned itself as a go-to supplier for businesses seeking reliable and efficient stepper motors. As the industry continues to evolve, the distributor remains dedicated to meeting the growing demand for precision motors and providing innovative solutions for its customers.

High-Quality High Precision Stepper Motor: A Comprehensive Guide

High-Quality high precision stepper motorIn the world of manufacturing and industrial automation, precision and reliability are of utmost importance. This is why the introduction of the high-quality high precision stepper motor from {company name} is creating a buzz in the industry. This innovative product is set to revolutionize the way businesses approach automation, offering superior performance and unmatched precision.The high precision stepper motor is designed to meet the demanding requirements of modern manufacturing processes. With a focus on accuracy and reliability, this cutting-edge technology is poised to set a new standard in the industry. The motor is engineered to deliver precise control and consistent performance, making it an ideal choice for a wide range of industrial applications.The secret behind the superior performance of this stepper motor lies in its advanced design and construction. Utilizing the latest advancements in technology, {company name} has developed a motor that delivers unparalleled precision and reliability. This means that businesses can rely on this motor to deliver consistent, high-quality performance in even the most demanding applications.One of the key features of this high precision stepper motor is its exceptional accuracy. With precise positioning capabilities, businesses can expect reliable and consistent performance across a wide range of operating conditions. This level of accuracy is essential for applications where precision is critical, such as CNC machining, 3D printing, and robotics.In addition to its precision, this stepper motor is also designed to deliver high torque and smooth operation. This means that businesses can expect superior performance and efficiency, reducing the risk of errors and downtime. With its robust construction and advanced engineering, this motor is built to withstand the rigors of industrial use, making it a reliable and cost-effective choice for businesses.{Company name} is a renowned leader in the field of industrial automation and motion control. With a strong focus on innovation and quality, the company has established a reputation for delivering cutting-edge solutions that meet the evolving needs of the industry. The introduction of the high precision stepper motor is a testament to {company name}'s commitment to excellence, and its dedication to staying at the forefront of technological advancements.With a team of highly skilled engineers and experts, {company name} has been able to develop a stepper motor that exceeds industry standards. Their dedication to research and development has resulted in a product that offers exceptional performance and reliability, setting a new benchmark in the field of motion control.The high precision stepper motor from {company name} is expected to have a significant impact on the industry, providing businesses with a reliable and cost-effective solution for their automation needs. With its advanced features and superior performance, this motor is set to become the go-to choice for businesses looking to enhance their manufacturing processes and achieve greater levels of precision and efficiency.As industries continue to evolve and demand higher levels of precision and reliability, the high-precision stepper motor from {company name} is well-positioned to meet these needs. With its advanced technology and innovative design, this motor is set to revolutionize the way businesses approach automation, setting a new standard for performance and reliability.

New High-Performance Gear Ratio Diameter Enhances Industrial Efficiency in China

Title: China's Latest Gear Ratio Diameter Revolutionizes Industrial ProcessesIntroduction:China, at the forefront of technological advancements, has introduced a groundbreaking gear ratio diameter that is set to redefine industrial processes. With a strong focus on innovation and cutting-edge manufacturing capabilities, Chinese companies have led the way in developing this game-changing gear technology. By efficiently maximizing power transmission, optimizing system performance, and improving overall productivity, this innovation is poised to catapult Chinese industries into a new era of growth and competitiveness. Gear Ratio Diameter: Revolutionizing Industrial Efficiency:The recently developed gear ratio diameter holds immense potential to revolutionize industrial efficiency across various sectors. Backed by extensive research and development, this gear technology is designed to enhance power transmission efficiency, reduce energy consumption, and ensure high levels of precision in industrial applications. Chinese manufacturing companies have duly acknowledged the importance of gear systems in enhancing overall productivity. Through the implementation of this gear ratio diameter, businesses can drive improvements in processes that rely on power transmission, such as automotive manufacturing, heavy machinery production, marine propulsion, and many others. This technology allows for the customization of gear systems to optimize torque requirements, resulting in significant cost savings and greater operational efficiencies.Furthermore, this advanced gear technology boasts the ability to minimize friction, reduce noise levels, and improve overall gear system performance. With better gear synchronization, industries can expect reduced downtime, enhanced reliability, and increased machine longevity. The Competitive Edge:China, being one of the global leaders in manufacturing, has recognized the significance of investing in innovative technologies to solidify its competitive edge. Chinese companies have transformed their gear manufacturing capabilities to ensure that the gear ratio diameter fulfills the dynamic needs of industries both nationally and internationally. By making use of advanced manufacturing techniques, such as CNC machining, automation, and precise quality control processes, Chinese manufacturers have achieved unparalleled levels of precision in gear production. This precision is crucial for the successful implementation of the gear ratio diameter, as even minor deviations can compromise the efficiency and performance of the system.Moreover, Chinese manufacturers have also focused on applying high-quality materials and rigorous testing processes to ensure the durability and longevity of their gear systems. This commitment to quality has allowed Chinese companies to gain the trust of domestic and international customers, solidifying their position as reliable suppliers of gear transmission solutions.Global Adaptation:The introduction of the gear ratio diameter technology by Chinese companies has received global attention and acclaim. Many international businesses, including those operating in developed countries with established industrial sectors, are recognizing the immense benefits of incorporating this gear technology into their operations.The ease of adaptability and customization provided by the gear ratio diameter technology is a key factor that attracts businesses from all corners of the globe. By offering tailor-made gear systems, Chinese manufacturers can accommodate specific industrial requirements, ensuring maximum efficiency and performance for each unique application.Additionally, the cost-effectiveness of these gear systems also appeals to international businesses. With Chinese manufacturers offering competitive pricing without compromising on quality, foreign industries can achieve significant cost savings while embracing cutting-edge technology.Future Outlook:Looking ahead, the development and implementation of the gear ratio diameter technology will continue to drive China's industrial growth and development. With a strong commitment to investing in research and development, Chinese manufacturers are poised to push the boundaries of gear technology even further.As industries across the globe seek ways to boost efficiency and productivity, Chinese gear systems are poised to become an essential component of their operations, ensuring seamless power transmission and maximum reliability. Chinese manufacturers will likely continue to innovate and refine gear systems to meet evolving industry demands and cement their position as leaders in the worldwide market.Conclusion:China's gear ratio diameter technology represents a significant milestone in the industrial sector. Its ability to optimize power transmission, enhance precision, reduce energy consumption, and provide cost-effective solutions has made it highly sought after globally. Backed by Chinese manufacturers' commitment to quality, adaptability, and manufacturing excellence, this gear technology is set to shape the future of industrial processes, positioning China at the forefront of global manufacturing innovation and competitiveness.

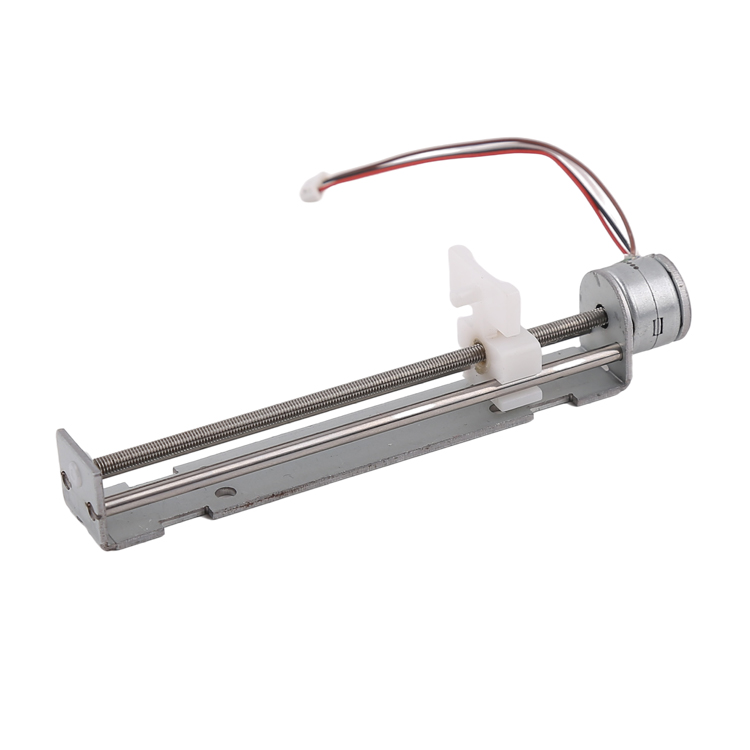

High-Quality Micro Stepper Motor with Lead Screw from China

China-based company {} has recently unveiled a micro stepper motor with lead screw that is set to revolutionize the field of automation and robotics. The new product is designed to provide precise and reliable movement in a compact and lightweight package, making it an ideal solution for a wide range of applications.The micro stepper motor with lead screw is a key component in many automated systems, and the advancements made by {} have the potential to greatly improve the performance and efficiency of these systems. With a focus on precision and reliability, the new product offers a level of performance that is unmatched in the industry.The micro stepper motor with lead screw is designed to provide smooth and accurate movement in a compact and lightweight package. It offers a high level of precision, making it well-suited for applications that require precise positioning and control. The motor is also highly efficient, producing minimal heat and consuming very little power. This makes it an ideal solution for applications where energy efficiency is a priority.One of the key features of the micro stepper motor with lead screw is its compact size. This makes it easy to integrate into a wide range of systems, including small or confined spaces where traditional motors would not fit. Its lightweight design also makes it easy to transport and install, further adding to its versatility and ease of use.In addition to its high level of performance, the micro stepper motor with lead screw is also designed to be highly reliable. It is built to withstand the rigors of continuous use, and it is engineered to operate smoothly and consistently over an extended period of time. This makes it an ideal choice for applications where downtime is not an option.The release of the micro stepper motor with lead screw represents a significant advancement in the field of automation and robotics. It offers a level of performance, precision, and reliability that is unmatched by any other product on the market. With its compact size, lightweight design, and energy efficiency, it is sure to become a key component in a wide range of automated systems.{} is a leading provider of automation and robotics solutions in China, with a strong track record of innovation and excellence. The company has a proven track record of developing cutting-edge products that push the boundaries of what is possible in the field of automation. With the release of the micro stepper motor with lead screw, {} is once again demonstrating its commitment to providing state-of-the-art solutions that meet the evolving needs of its customers.With its new micro stepper motor with lead screw, {} is set to further solidify its position as a leader in the field of automation and robotics. The company's dedication to innovation, quality, and customer satisfaction is evident in every product it releases, and the new motor is no exception. As automation and robotics continue to play an increasingly important role in a wide range of industries, {} is well-positioned to meet the growing demand for high-performance, reliable solutions.

Compact DC Motor for Small Applications

DC Motor Small, a leading manufacturer of small electric motors, has announced the release of their latest product, the MiniDrive 2000. This compact but powerful motor is designed to provide high performance in a variety of applications, from robotics and automation to consumer electronics and automotive systems.With over 20 years of experience in the industry, DC Motor Small has established itself as a trusted supplier of small electric motors, known for their reliability and precision engineering. The company has a strong track record of delivering innovative solutions to meet the growing demands of the market, and the MiniDrive 2000 is no exception.The MiniDrive 2000 features a compact design, making it ideal for applications where space is limited. Despite its small size, this motor packs a punch, offering high torque and efficient performance. With a wide operating range and customizable options available, the MiniDrive 2000 can be tailored to suit specific requirements, making it a versatile choice for a range of applications.One of the key features of the MiniDrive 2000 is its advanced control system, which allows for seamless integration with different types of control electronics. This flexibility makes it easy to incorporate the motor into existing systems or to develop new applications that require precise motor control."We are excited to announce the release of the MiniDrive 2000," said a spokesperson for DC Motor Small. "This motor represents the latest in our ongoing commitment to providing high-quality, reliable electric motors for a wide range of applications. We believe that the MiniDrive 2000 will set new standards for performance and versatility in the industry."In addition to its technical capabilities, the MiniDrive 2000 is also designed with sustainability in mind. The motor is engineered to be energy efficient, reducing power consumption and minimizing environmental impact. This aligns with DC Motor Small's dedication to producing environmentally-friendly products that meet the evolving needs of the industry.The release of the MiniDrive 2000 further solidifies DC Motor Small's position as a leader in the small electric motor market. The company's reputation for delivering exceptional products and providing outstanding customer support has earned them a loyal customer base and has positioned them for continued success in the future.With a global presence, DC Motor Small is able to serve customers around the world, offering reliable supply chain management and technical support. Their team of experienced engineers and technicians are dedicated to ensuring that customers receive the best possible solutions for their motor requirements, whether it's for a small-scale project or a large-scale industrial application.As the demand for small electric motors continues to grow across a wide range of industries, the release of the MiniDrive 2000 demonstrates DC Motor Small's commitment to meeting the evolving needs of the market. With its combination of high performance, compact design, and sustainability features, the MiniDrive 2000 is set to make a significant impact in the industry and further solidify DC Motor Small's reputation as a leading supplier of small electric motors.

Understanding the Advantages of 2 Phase Stepper Motors for Efficient Motion Control

Title: Cutting-Edge 2-Phase Stepper Motors Revolutionize the Industry: A Breakthrough from Introduction:The relentless quest for innovation continues to drive advancements in the realm of automation and robotics. In line with this pursuit, a leading industry player, [Company Name], has announced a groundbreaking development in the form of their highly efficient 2-Phase Stepper Motors. These cutting-edge motors promise to redefine the standards of precision, reliability, and performance, setting a new benchmark for the industry.Phase 1: Transforming Automation with Unparalleled Precision[Company Name] unveils its latest 2-Phase Stepper Motors, aiming to revolutionize the automation landscape. With a focus on precision, these motors offer a level of accuracy that surpasses their closest competitors. Equipped with advanced magnetic technology, they provide incremental rotations, allowing for pin-point positioning in a wide range of applications. This groundbreaking precision is hailed as a game-changer, enabling robotic systems to perform intricate tasks with unprecedented accuracy and responsiveness.Phase 2: Unmatched Reliability for Increased ProductivityAlongside remarkable precision, [Company Name]'s 2-Phase Stepper Motors deliver unmatched reliability, ensuring consistent performance even in the most demanding environments. By incorporating state-of-the-art design enhancements, these motors exhibit exceptional durability even when subjected to extreme operational conditions. With extended operational lifespans and reduced maintenance requirements, businesses utilizing these motors can experience heightened productivity and cost savings.Phase 3: Optimized Performance for Versatile Applications[Company Name]'s 2-Phase Stepper Motors exhibit superior performance across a vast array of applications. From manufacturing processes to robotics, from medical devices to 3D printers, these motors have the versatility to drive various automated systems efficiently. With customizable torque settings and adaptable speed control, they empower businesses to optimize their operations and streamline processes for maximum efficiency. This versatility guarantees that organizations in multiple industries can reap the benefits of these cutting-edge motors.Phase 4: Tackling Industry Challenges Head-OnRecognizing the evolving needs and challenges faced by industries today, [Company Name] has incorporated advanced features into their 2-Phase Stepper Motors, effectively addressing key concerns. With enhanced heat dissipation mechanisms, the motors minimize the risk of overheating, thereby mitigating the potential for operational failures. Furthermore, the motors integrate intelligent power management systems, allowing for efficient energy consumption and reduced power wastage. These advancements signify a significant step towards sustainable and energy-efficient automation solutions.Phase 5: A Commitment to Continuous Innovation[Company Name] is committed to pushing the boundaries of technological innovation, continually striving to exceed industry expectations. Their relentless pursuit of product development and improvement ensures that their 2-Phase Stepper Motors remain at the forefront of automation solutions. Collaborating with industry leaders, [Company Name] aims to drive progress and shape the future of automation.Conclusion:With the launch of their state-of-the-art 2-Phase Stepper Motors, [Company Name] is poised to revolutionize the industry with their exceptional precision, reliability, and performance. These motors open up a world of possibilities for businesses, enabling them to streamline operations, increase productivity, and achieve new levels of automation efficiency. As [Company Name] continues to innovate and collaborate with industry frontrunners, the future of automation looks brighter than ever before.