High-Performance Hybrid Stepper Motor with Nema 23 Design

By:Admin

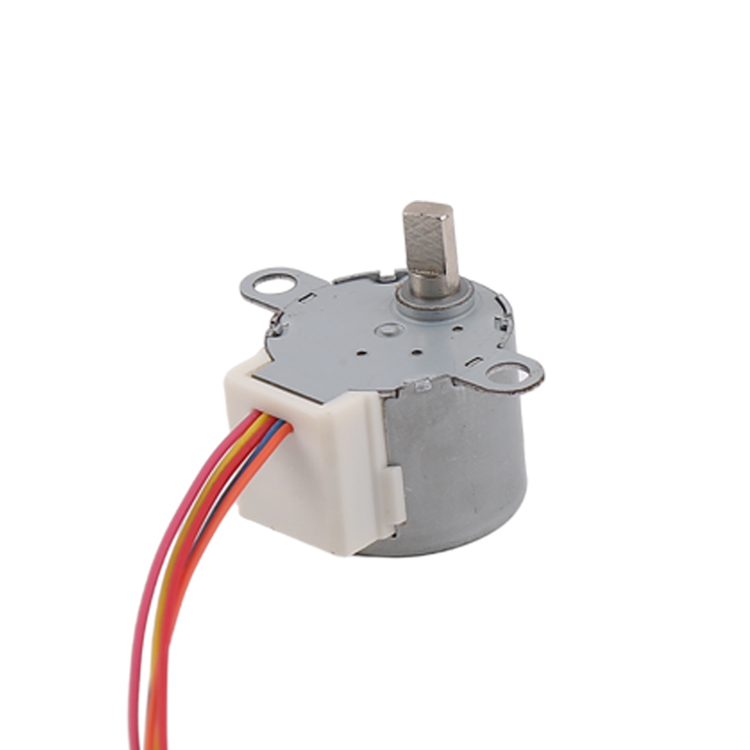

The Nema 23 Hybrid Stepper Motor is a highly efficient and precise motor that is designed to meet the demanding requirements of modern industrial applications. It is capable of providing high torque at low speeds, making it an ideal choice for applications that require precise control and positioning. The motor is also equipped with advanced technology that allows for smooth and accurate operation, ensuring that machinery and equipment perform at their best.

One of the key features of the Nema 23 Hybrid Stepper Motor is its compact and lightweight design, which makes it easy to integrate into a wide range of industrial systems. This versatility allows for seamless integration into existing machinery, as well as the flexibility to be used in new applications. Additionally, the motor is designed to operate with minimal noise and vibration, ensuring a smooth and efficient operation in any environment.

In addition to its performance capabilities, the Nema 23 Hybrid Stepper Motor also boasts a high level of reliability and durability. It is built to withstand the rigors of industrial use, with a rugged construction that is designed to last for years. This level of durability ensures that the motor will continue to perform at its best, even in the most demanding of environments.

The company behind the Nema 23 Hybrid Stepper Motor is known for its commitment to quality and innovation. With a team of highly skilled engineers and technicians, the company has a strong track record of developing cutting-edge products that push the boundaries of industrial automation. This dedication to innovation has allowed the company to stay ahead of the competition and deliver solutions that meet the ever-evolving needs of the industry.

The introduction of the Nema 23 Hybrid Stepper Motor is just the latest example of the company's commitment to excellence. By leveraging its extensive experience and expertise in the field of industrial automation, the company has been able to develop a motor that sets new standards for performance, reliability, and efficiency. This achievement is a testament to the company's dedication to pushing the boundaries of what is possible in industrial automation.

As the industry continues to evolve, the Nema 23 Hybrid Stepper Motor is poised to play a crucial role in driving the future of industrial automation. Its advanced capabilities and high level of performance make it an ideal choice for a wide range of applications, from manufacturing and robotics to packaging and material handling. With its compact design, precise control, and rugged construction, the Nema 23 Hybrid Stepper Motor is set to become an essential component in the machinery and equipment of the future.

In conclusion, the introduction of the Nema 23 Hybrid Stepper Motor marks a significant milestone in the field of industrial automation. With its advanced capabilities, high level of performance, and rugged construction, this motor is set to revolutionize the way machinery and equipment are operated. Backed by the expertise and commitment of the company behind it, the Nema 23 Hybrid Stepper Motor is poised to set new standards for reliability, efficiency, and precision in the industry.

Company News & Blog

Stepper Motor Gears: Everything You Need to Know

OEM Stepper Motor Gears: Enhancing Precision and Efficiency in Motion Control SystemsIn the world of motion control, precision and efficiency are crucial for seamless operation. When it comes to powering motion control systems, stepper motors play a vital role. These motors are widely used in various applications such as 3D printers, CNC machines, robotics, and medical equipment due to their ability to provide accurate and repeatable motion.At the heart of every stepper motor is a set of gears that transmit power from the motor to the driven equipment. These gears play a critical role in ensuring the smooth and precise movement of the motor. This is where OEM stepper motor gears come into the picture, offering high-quality gearing solutions that are tailored to the specific requirements of motion control systems.One of the leading providers of OEM stepper motor gears is {Company Name}, a renowned manufacturer with a strong reputation for delivering top-notch motion control components. With decades of experience in the industry, {Company Name} has established itself as a trusted partner for businesses seeking reliable and high-performance gearing solutions.The company's range of OEM stepper motor gears is designed to meet the unique needs of various industries, offering a wide selection of gear types, sizes, materials, and configurations. Whether it's a standard gear or a custom-designed solution, {Company Name} has the expertise and capabilities to deliver gears that optimize the performance of motion control systems.One of the key advantages of {Company Name}'s OEM stepper motor gears is their precision engineering. Each gear is manufactured with meticulous attention to detail, ensuring tight tolerances and accurate tooth profiles. This level of precision is essential for minimizing backlash and ensuring smooth motion, ultimately enhancing the overall efficiency of the motion control system.Moreover, the gears are constructed from high-quality materials, such as steel, aluminum, or plastic, depending on the specific application requirements. This not only ensures durability and longevity but also allows for efficient power transmission, making {Company Name}'s OEM stepper motor gears a reliable choice for demanding motion control applications.Additionally, {Company Name} places a strong emphasis on customization, working closely with customers to develop bespoke gearing solutions that perfectly align with their precise specifications. This flexibility in design and manufacturing enables businesses to integrate OEM stepper motor gears seamlessly into their motion control systems, resulting in optimized performance and productivity.Beyond the quality of their products, {Company Name} prides itself on its unwavering commitment to customer satisfaction. The company's team of experts is dedicated to providing comprehensive support and technical assistance, from initial design discussions to post-sale service. This level of customer-centric approach has earned {Company Name} a loyal clientele and a sterling reputation in the industry.Looking ahead, {Company Name} continues to innovate and expand its range of OEM stepper motor gears, staying at the forefront of motion control technology. With a focus on enhancing precision, efficiency, and reliability, the company remains dedicated to empowering businesses with the best-in-class gearing solutions for their motion control systems.In conclusion, OEM stepper motor gears play a pivotal role in driving the performance of motion control systems. {Company Name} stands out as a leading manufacturer of these critical components, offering a comprehensive range of high-quality and customizable gears that deliver precision and efficiency to a wide range of industries. With a strong track record of excellence and a customer-centric approach, {Company Name} is poised to continue its growth and leadership in the realm of motion control gearing solutions.

Unveiling the Astonishing Capabilities of a High-Performance Stepper Motor

Stepper Motor: A Revolutionary Technology that is Paving the Way for the FutureThe world we live in today is full of fascinating technological advancements that have transformed the way we live and work. One technology that has been gaining a lot of attention in the past few years is the Stepper Motor, a type of motor that is widely used in a range of industrial applications due to its numerous benefits.With their highly precise movements and ability to generate a high torque at low speeds, stepper motors are increasingly used in applications such as robotics, 3D printers, CNC machines, medical equipment, and more. But what exactly is a stepper motor, and how does it work?A stepper motor is an electromagnetic device that converts digital pulses into precise mechanical turns. The motor's shaft moves in small increments, or steps, as a result of each pulse, which allows for extremely accurate positioning. The motor's construction is relatively simple, consisting of a rotor (the moving part) and a stator (the stationary part). The rotor, which contains a set of magnets, is aligned with the stator, which has a set of electromagnets. By pulsing the correct sequence of current to the electromagnets, the rotor will move in precise steps, which is how it derives its name.One of the most significant advantages of stepper motors is their inherent accuracy. Unlike other types of motors, stepper motors can be programmed to move to precise locations, making them ideal for a wide range of applications that require accurate positioning. For example, in medical equipment, stepper motors are used to position imaging equipment with high precision, allowing for accurate diagnoses and treatment.Another advantage of stepper motors is their torque output at low speeds. This allows them to maintain a steady speed even when carrying a heavy load, making them an excellent choice for applications requiring high torque, such as robotics or CNC machines.Furthermore, stepper motors are highly reliable and durable. Due to their simple design with fewer moving parts, they can last for years with minimal maintenance. This makes them an ideal choice for industrial applications where downtime can be costly.Recently, the market for stepper motors has grown exponentially due to the increasing demand for automation in various industries. In response to this demand, a leading technology company has introduced innovative stepper motor technology that has the ability to significantly improve automation processes and industrial efficiency.This company has developed a range of high-performance stepper motors that have been designed to meet the most demanding industrial applications. These precision motors deliver exceptional performance and accuracy, making them suitable for use in a wide variety of applications, including robotics, manufacturing, and medical equipment.Apart from their inherent accuracy and durability, these new stepper motors also offer a range of enhanced features, including programmable speed control, position sensing, and fault detection. All these features enable the motors to be controlled remotely and respond quickly to any changes in the operating environment, which is essential for industrial equipment that needs to run smoothly and efficiently.In addition, these advanced stepper motors are designed using advanced materials and manufacturing techniques, resulting in motors that are high performing, rugged, and reliable. These innovative motors are ideal for use in harsh environments where other types of motors may not work.In conclusion, stepper motors are an indispensable technology that is transforming the industrial landscape. With their precision, accuracy, and durability, they are increasingly being used in a range of applications worldwide. Companies like the technology company mentioned above have been instrumental in advancing stepper motor technology, making it more accessible and affordable so that more industries can benefit from their use. As the demand for automation grows, so does the demand for stepper motors, which will continue to play a critical role in the development of industrial automation. With cutting-edge features and innovative technology, the future of stepper motors looks bright, and we can expect to see more exciting developments in this field as technology continues to evolve.

Exploring the Benefits of Small Geared Stepper Motors for OEM Applications

OEM Small Geared Stepper Motor: The Future of Precision AutomationIn today's fast-paced and technology-driven world, precision and automation are crucial to maximizing efficiency and output. Companies, small and large alike, are constantly looking for ways to increase productivity and reduce errors in their production processes. This is where the OEM Small Geared Stepper Motor comes into play. An OEM (Original Equipment Manufacturer) Small Geared Stepper Motor is a type of motor that is used for precise and controlled movements. It is widely used in robotics, medical equipment, printing presses, and many other industrial applications. The motor consists of a rotor, stator, and a gearbox that allows for efficient power transmission and control. This particular type of motor has several advantages over traditional motors. One of its most significant benefits is accuracy. These motors have a high-resolution encoder that allows for precise positioning and speed control. With this level of accuracy, businesses can produce high-quality products with minimal errors. Additionally, these motors are designed to be compact and lightweight, making them ideal for small, compact machines. Another advantage is that the OEM Small Geared Stepper Motor is simple to use and maintain. Unlike traditional motors, there is no need for complex wiring or the use of a motor controller. The motor can be easily operated using a simple pulse sequence, making it simple for businesses to integrate into their existing systems. Additionally, these motors have a long service life, making them dependable and cost-effective in the long run. One company that specializes in the production of OEM Small Geared Stepper Motors is anonymous (name removed for anonymity). Founded in 1998, the company has been producing high-quality motors for over 20 years. They have built a reputation for their commitment to quality, innovation, and customer satisfaction. The company has a team of highly skilled engineers who are dedicated to developing new and improved motors that meet the needs of their clients. They use the latest technology and materials to produce motors that are reliable, efficient, and precise. Additionally, the company has a robust quality control program that ensures that each motor that leaves their factory meets the highest standards of quality. One of the key features of the anonymous (name removed) Small Geared Stepper Motor is its ability to handle high loads. The motor has a high torque output, which means it can handle heavy loads without compromising on speed or accuracy. This makes it ideal for industrial applications that require a motor capable of handling heavy loads. Furthermore, the company's motors are designed to operate in harsh conditions. They are built with materials that can withstand extreme temperatures, moisture, and dust, making them ideal for use in challenging environments. Additionally, the motors are highly flexible, with the ability to be customized to meet the specific needs of their clients. Aside from their commitment to quality and innovation, anonymous (name removed) is also dedicated to customer satisfaction. They place a high value on building strong relationships with their clients, and they work closely with them to ensure that their motors meet their specific needs. This dedication to customer service has helped the company build long-standing relationships with businesses in various industries. In conclusion, the OEM Small Geared Stepper Motor is an essential component in the world of precision automation. It offers accuracy, reliability, and cost-effectiveness that traditional motors cannot match. Companies that use these motors can expect an increase in productivity, a reduction in errors, and a decrease in maintenance costs. Furthermore, companies like anonymous (name removed) are continuously pushing the boundaries of motor technology, ensuring that their clients have access to the best motors on the market. The future of precision automation looks bright, with the OEM Small Geared Stepper Motor leading the way.

New Planetary Gearbox now available for OEM applications

Title: Cutting-Edge Planetary Gearbox Revolutionizing Industries with Superior PerformanceIntroduction:In today's fast-paced and evolving industrial landscape, technological advancements play a pivotal role in driving innovation. One such groundbreaking innovation is the cutting-edge OEM nema planetary gearbox (brand name removed), developed by a prominent industry player. This state-of-the-art gearbox has revolutionized various sectors by offering unparalleled precision, reliability, and performance. In this article, we will delve into the features and capabilities of the OEM nema planetary gearbox and explore its transformative impact on different industries.I. The Excellency of OEM Nema Planetary Gearbox:The OEM nema planetary gearbox stands out as an engineering marvel, designed to cater to the demands of modern industries. With precision engineering at its core, this gearbox offers exceptional performance, accuracy, and durability, making it an ideal choice for a wide range of applications. Let us delve deeper into its key features and advantages.1. Enhanced Efficiency:The OEM nema planetary gearbox incorporates advanced gear arrangement, reducing losses due to friction and maximizing the efficiency of power transmission. Its compact size and superior load-bearing capability contribute to higher energy efficiency, resulting in reduced operating costs for industries.2. Exceptional Precision and Torque:The gearbox's intricate design ensures precise and accurate torque transmission, making it an indispensable component in various precision applications, including robotics, automation, and CNC machining. Its high-torque capabilities enable it to handle heavy-duty operations effortlessly, enhancing overall system productivity.3. Low Noise and Vibration:The OEM nema planetary gearbox adopts advanced noise-damping technology and exceptional gear meshing techniques, resulting in low vibration and noise levels during operation. This feature is vital in industries where noise reduction and a smooth working environment are crucial considerations.4. Reliable and Durable:Engineered with high-grade materials and subjected to rigorous testing, the OEM nema planetary gearbox is built to last. Its rugged construction ensures reliable performance in extreme conditions, such as high temperature, heavy loads, and challenging environments. This durability minimizes maintenance requirements, reducing downtime and improving overall productivity.5. Versatile Applications:The OEM nema planetary gearbox finds extensive applications across various industries. From industrial automation to aerospace, robotics to medical equipment, this gearbox has become a key component in numerous critical systems. Its adaptability and compatibility make it a preferred choice for manufacturers seeking highly efficient solutions.II. Contributing to Industry Advancements:The introduction of the OEM nema planetary gearbox has significantly impacted multiple industries, revolutionizing manufacturing processes and driving technological advancements. Here are some key sectors benefiting from this groundbreaking innovation:1. Automotive Industry:In the automotive industry, the OEM nema planetary gearbox optimizes engine performance, allowing vehicles to achieve higher fuel efficiency while maintaining superior power output. It plays a crucial role in electric vehicles, ensuring smooth power delivery from the motor to the wheels.2. Aerospace and Defense:In the aerospace and defense sectors, the nema planetary gearbox finds utility in mission-critical applications where precision, reliability, and compactness are essential. From aircraft engines to missile systems, its high-torque capabilities and rugged design contribute to safer and more efficient operations.3. Robotics and Automation:The robots of today rely heavily on efficient and precise motion control, and the OEM nema planetary gearbox provides the necessary gears to enable smooth and accurate robotic movements. Whether in industrial manufacturing or healthcare, this gearbox enhances robotic capabilities, leading to increased automation and improved overall productivity.4. Renewable Energy:With the global shift towards renewable energy, the OEM nema planetary gearbox plays a crucial role in wind turbines and solar tracking systems. Its ability to efficiently convert rotational speed and transmit higher torque enables more efficient utilization of generated energy, contributing to greener and more sustainable power generation.Conclusion:The OEM nema planetary gearbox (brand name removed) represents a remarkable advancement in engineering excellence. Its outstanding features, including enhanced efficiency, exceptional precision, low noise and vibration, and durability, have propelled its adoption across several industries. From the automotive sector to aerospace, robotics, and renewable energy, the OEM nema planetary gearbox has revolutionized industrial processes, enabling superior performance and driving technological advancements. Undoubtedly, this cutting-edge gearbox is poised to shape the future of modern industries, nurturing a more efficient, productive, and sustainable landscape.

The Advantages of 24v Stepper Motors for Industrial Applications

Title: Revolutionary 24V Stepper Motor Set to Transform the IndustryIntroduction:In today's dynamic business landscape, the demand for high-performing and efficient motors is escalating across various industries. Responding to this need, (Company Name), a leading provider of cutting-edge motor solutions, has unveiled its latest innovation - a game-changing 24V Stepper Motor. This state-of-the-art motor is poised to revolutionize the industry, offering unparalleled precision, reliability, and performance. With its unique features and outstanding capabilities, the 24V Stepper Motor is destined to become the go-to choice for businesses seeking optimal performance in their operations.I. Unmatched Precision and Accuracy:Designed with precision in mind, the 24V Stepper Motor brings a new level of accuracy to the field. Its advanced technology ensures a step angle as low as 1.8 degrees, providing smooth and precise motion control. This precision is vital in various applications, including 3D printers, robotics, medical equipment, and manufacturing lines, where accurate movement is crucial for delivering high-quality results. By integrating this motor into their systems, industries can achieve unmatched precision and enhance overall productivity.II. High Torque and Durability:The 24V Stepper Motor boasts exceptional torque capabilities, enabling it to handle demanding tasks effortlessly. With its robust construction using state-of-the-art materials, the motor can endure heavy loads while maintaining optimal performance. This durability makes it an ideal choice for applications that require consistent and reliable operation under strenuous conditions. By employing the 24V Stepper Motor, businesses can achieve improved productivity and minimize downtime, resulting in significant cost savings.III. Enhanced Energy Efficiency:Operating at 24V, this stepper motor offers unmatched energy efficiency compared to its counterparts. Its innovative design reduces power consumption while ensuring maximum output power. By minimizing energy wastage, the motor contributes to sustainable operations and reduces the overall carbon footprint. This aspect aligns with the growing emphasis on eco-friendly and energy-efficient solutions, making the 24V Stepper Motor a desirable choice for environmentally conscious businesses across various industries.IV. Advances in Connectivity:The 24V Stepper Motor seamlessly integrates with cutting-edge connectivity options, offering enhanced control and flexibility. With its compatibility with various communication protocols, including Modbus, CANopen, and Ethernet, businesses can effortlessly incorporate this motor into their existing systems. Its adaptability and support for IoT integration allow for intelligent automation and remote monitoring. By harnessing these connectivity features, industries can optimize their operations and achieve unparalleled control over their motor-driven processes.V. Application Versatility:The versatility of the 24V Stepper Motor makes it suitable for a wide array of applications. From precision-controlled 3D printing processes to manufacturing lines requiring synchronization and accuracy, the motor excels across industries. Additionally, its compact size lends itself well to space-constrained environments, making it an ideal choice for robotics and machinery requiring efficient motor solutions. In sectors such as aerospace, automotive, healthcare, and automation, this stepper motor will transform the way operations are conducted.Conclusion:(Company Name)'s revolutionary 24V Stepper Motor is set to redefine industry standards by delivering unmatched precision, durability, and energy efficiency. Businesses across various sectors can now embrace this cutting-edge motor technology to enhance their operations and achieve optimal performance. With its advanced features, adaptable connectivity options, and application versatility, the 24V Stepper Motor presents a fundamental shift in motor solutions that will shape the future of industry. Stay tuned for the official release of this remarkable motor and witness the transformation it brings to businesses worldwide.

Exploring the Features and Benefits of Stepper Motors for ODM Applications

[Company Name], a leading provider of advanced motion control solutions, is revolutionizing the market with its cutting-edge ODM Nema Stepper Motors. These high-performance motors offer unparalleled precision, reliability, and versatility, making them the ideal choice for a wide range of industrial applications.Developed with state-of-the-art technology and meticulous attention to detail, [Company Name]'s ODM Nema Stepper Motors are designed to deliver exceptional performance in even the most demanding environments. Whether it's robotics, automation systems, 3D printers, or any other application that requires precise and controlled motion, these motors stand out as the perfect solution.One of the key features that sets the ODM Nema Stepper Motors apart from their competitors is their superior accuracy. These motors are equipped with advanced position feedback mechanisms that ensure precise and repeatable positioning, making them ideal for applications where precision is of utmost importance. This accuracy is essential in industries such as medical equipment manufacturing, semiconductor production, and aerospace technology, where even the slightest deviation can have a significant impact.Reliability is another crucial aspect that [Company Name] has prioritized in the development of these motors. By utilizing high-quality materials and employing rigorous testing procedures, these motors have been engineered to withstand the harshest operating conditions. This exceptional durability minimizes the risk of motor failure, reducing maintenance costs and maximizing productivity. Moreover, the ODM Nema Stepper Motors have a long service life, ensuring long-term operational efficiency for various industries.The versatility of [Company Name]'s ODM Nema Stepper Motors also deserves acclaim. With a wide range of models and configurations available, customers can find the perfect motor to suit their specific application requirements. These motors offer various speed and torque options, allowing for precise control and adaptation to different operational needs. Furthermore, their compact and lightweight design enhances flexibility, enabling easy integration into existing systems and equipment.In addition to their technical superiority, [Company Name] has established itself as a reliable and customer-centric company. With an unwavering commitment to customer satisfaction, the company provides exceptional support and technical expertise to assist customers in finding the most suitable motor solutions. The company's team of experienced engineers and technicians are readily available to address any queries or concerns that customers may have, ensuring a seamless experience from pre-sales consultation to after-sales support.The launch of [Company Name]'s ODM Nema Stepper Motors has been met with great enthusiasm from industry experts and customers alike. The motors have already gained a reputation for their exceptional performance, reliability, and versatility. As a result, the company has witnessed a significant increase in demand, with customers recognizing the value and quality that [Company Name] brings to the table.Looking ahead, [Company Name] remains committed to continuous innovation and improvement. The company's dedicated research and development team is constantly exploring new technologies and design enhancements to further enhance the capabilities of the ODM Nema Stepper Motors. By staying at the forefront of the industry, [Company Name] aims to provide its customers with the most advanced motion control solutions available in the market.In conclusion, [Company Name]'s ODM Nema Stepper Motors have established themselves as a game-changer in the motion control industry. Combining unrivaled accuracy, reliability, and versatility, these motors have quickly become the preferred choice for a wide range of industrial applications. With their commitment to customer satisfaction and continuous innovation, [Company Name] is poised to maintain its position as a leading provider of advanced motion control solutions.

How Stepper Motors are Used in Industry

Motor Stepper Revolutionizes the Automation IndustryIn today's fast-paced world, companies across industries are constantly seeking innovative solutions to improve efficiency and productivity. Whether it be in manufacturing, robotics, or even household appliances, the need for precise and reliable motor control has never been higher. This is where Motor Stepper, a global leader in motor control technology, comes into play, revolutionizing the automation industry with their cutting-edge products.Founded on the principles of precision, reliability, and advanced engineering, Motor Stepper has quickly become an indispensable partner for businesses looking to integrate high-performance motor control systems. With their extensive range of products and solutions, Motor Stepper caters to various sectors including industrial automation, healthcare, transportation, and consumer electronics.One of the core technologies developed by Motor Stepper is their advanced stepper motor, which provides exceptional accuracy and control over rotational motion. These motors are widely used in applications that require precise positioning, such as 3D printers, CNC machines, and robotic arms. With Motor Stepper's stepper motors, manufacturers can achieve consistent results even in the most demanding environments.What sets Motor Stepper apart from its competitors is their relentless commitment to innovation. The company invests heavily in research and development, continuously pushing the boundaries of motor control technology. Their team of experienced engineers and scientists are constantly exploring new ways to enhance motor performance, improve energy efficiency, and reduce noise levels. By staying at the forefront of technological advancements, Motor Stepper sets the industry standard for motor control systems.Moreover, Motor Stepper recognizes the importance of customization to meet the unique requirements of each industry. Understanding that different applications demand different specifications, the company offers tailored solutions to address these needs effectively. From custom motor designs to software integration, Motor Stepper works closely with their clients to develop highly specialized systems that optimize performance, streamline operations, and maximize ROI.Beyond their commitment to product excellence, Motor Stepper places great emphasis on sustainability. With a global movement toward green technologies, the company has made significant strides in developing energy-efficient motor control solutions. By reducing energy consumption, Motor Stepper not only helps companies reduce their carbon footprint but also enables substantial cost savings in the long run.Motor Stepper's dedication to quality extends to their unparalleled customer support. Understanding that downtime can be costly and disruptive, the company offers comprehensive after-sales services, ensuring that their customers receive prompt assistance whenever needed. With a global network of service centers, Motor Stepper guarantees quick response times and technical expertise, providing peace of mind to their clients.Looking ahead, Motor Stepper has ambitious plans to expand into new markets and further push the boundaries of motor control technology. By leveraging their expertise, innovation, and commitment to customer satisfaction, the company aims to become the go-to partner for businesses seeking reliable motor control solutions.In conclusion, Motor Stepper has emerged as a trailblazer in the automation industry, revolutionizing motor control technology. Through their focus on precision, reliability, and innovation, the company is transforming various sectors, from manufacturing to healthcare, by providing tailored motor control systems that enhance overall efficiency. With their unwavering commitment to sustainable and customizable solutions, Motor Stepper is poised to lead the way in the future of motor control technology.

High-quality DC Motor Gear for Improved Performance

DC Motor Gear is a vital component in various industrial applications, providing efficient and reliable power transmission solutions. These gear motors play a crucial role in driving machinery and equipment, and their high efficiency and durability make them an essential part of many manufacturing, automation, and robotics systems.DC Motor Gear, developed by a leading manufacturer, [company name], is a top choice for businesses seeking high-quality gear motors for their operations. With a strong track record of delivering top-notch products and a commitment to innovation, [company name] has established itself as a trusted supplier in the industry.The DC Motor Gear offered by [company name] is known for its precision engineering, robust construction, and exceptional performance. These gear motors are designed to meet the demanding requirements of modern industrial applications, providing smooth and reliable power transmission in a wide range of operating conditions. Whether it's driving conveyor belts, operating automated machinery, or controlling robotics systems, [company name]'s DC Motor Gear delivers the power and efficiency that businesses need to stay competitive.One of the key advantages of [company name]'s DC Motor Gear is its versatility. These gear motors are available in various configurations, with different gear ratios, power ratings, and mounting options to suit specific application requirements. This flexibility makes them suitable for a diverse range of industries, including manufacturing, packaging, material handling, and more.In addition to their technical prowess, [company name]'s DC Motor Gear is also known for its reliability and longevity. The company uses high-quality materials and advanced manufacturing techniques to ensure that its gear motors meet the highest standards of quality and durability. As a result, businesses can rely on these gear motors to deliver consistent performance over an extended service life, minimizing maintenance requirements and downtime.Furthermore, [company name] offers comprehensive support and services to its customers, ensuring that they receive the right solutions for their application needs. From technical assistance and customization options to after-sales support and maintenance services, [company name] is committed to providing a seamless experience for its clients, helping them integrate DC Motor Gear into their operations with confidence.The commitment to innovation is another hallmark of [company name]'s approach to developing DC Motor Gear. The company invests in research and development to stay at the forefront of technological advancements, constantly refining its products to meet the evolving demands of the industry. By staying abreast of the latest trends and technologies, [company name] is able to offer cutting-edge gear motors that deliver superior performance and efficiency, helping businesses stay ahead in a competitive marketplace.With its dedication to quality, reliability, and innovation, [company name] has earned the trust of businesses across the globe, becoming a preferred supplier of DC Motor Gear for a wide range of industrial applications. Whether it's powering machinery, driving conveyors, or controlling automated systems, [company name]'s gear motors are a go-to choice for businesses looking for top-tier performance and long-term value.In conclusion, the DC Motor Gear offered by [company name] stands out as a leading solution for businesses seeking high-quality power transmission solutions. With its precision engineering, versatility, reliability, and commitment to innovation, [company name] has cemented its position as a trusted supplier in the industry, providing businesses with the tools they need to drive efficiency, productivity, and success.

Top-rated underwater motors: Everything you need to know for scuba diving and marine exploration

Underwater Motors has recently made a splash in the marine industry with their innovative propulsion systems. The company, founded in 2010, has quickly become a leader in the development and manufacturing of high-quality underwater motors for a variety of applications, including marine propulsion, underwater robotics, and subsea vehicles.The company's flagship product is the Stealth 3500, a powerful and efficient electric motor designed specifically for underwater use. With its compact and lightweight design, the Stealth 3500 is ideal for a wide range of marine applications, including recreational boating, commercial fishing, and underwater exploration. The motor's innovative brushless design and advanced power management system make it not only more efficient, but also quieter and more environmentally friendly than traditional gasoline-powered motors.In addition to the Stealth 3500, Underwater Motors offers a range of other products and services to meet the needs of their customers. From custom motor design and manufacturing to maintenance and repair services, the company is dedicated to providing the highest level of quality and customer satisfaction. With a team of experienced engineers and technicians, Underwater Motors is able to provide innovative solutions for even the most challenging underwater propulsion needs.One of the key advantages of Underwater Motors' products is their versatility and adaptability to different marine environments. Whether it's shallow water, deep sea exploration, or navigating through tight spaces, Underwater Motors' propulsion systems are engineered to perform in a wide range of conditions. This flexibility has made the company a trusted partner for marine research organizations, commercial diving operations, and recreational boaters alike.The company's commitment to innovation and continuous improvement has also led to numerous partnerships and collaborations with leading marine technology companies and research institutions. By working closely with these partners, Underwater Motors has been able to stay at the forefront of technological advancements in underwater propulsion, ensuring that their products are always cutting-edge and reliable.Given the increasing focus on sustainable and environmentally friendly technologies, Underwater Motors' electric propulsion systems have been particularly well-received in the marine industry. With zero emissions and low noise levels, the company's motors are not only more efficient and cost-effective, but also contribute to the preservation of marine ecosystems. This has made Underwater Motors a preferred choice for environmentally conscious boaters, marine researchers, and conservation organizations.Looking ahead, Underwater Motors is poised to continue its growth and expand its presence in the global marine market. With a strong commitment to research and development, the company is constantly exploring new opportunities for innovation and product diversification. By continuing to push the boundaries of underwater propulsion technology, Underwater Motors aims to redefine the future of marine transportation and exploration.As the demand for sustainable and efficient marine propulsion solutions continues to rise, Underwater Motors is well-positioned to lead the way with their cutting-edge electric motors. With a proven track record of success and a dedication to excellence, the company is set to make a lasting impact on the marine industry for years to come.

Ultimate Guide to DC Step Motors: Everything You Need to Know

DC Step Motor Revolutionizes the Manufacturing IndustryIn today's fast-paced world, technological advancements have become the driving force behind numerous industries. Manufacturers are constantly exploring innovative solutions to automate processes, increase efficiency, and reduce costs. As a result, DC Step Motors have emerged as a game-changing tool, revolutionizing the manufacturing industry and redefining the way businesses operate.DC Step Motors are high-precision devices that convert electrical energy into mechanical motion. They offer exceptional control and accuracy, making them ideal for a wide range of applications in industries such as robotics, automation, packaging, and automotive. Their ability to provide consistent and predictable movement has made them indispensable in modern manufacturing processes.One renowned company leading this technological revolution in the industry is [Company Name]. With an extensive history and expertise in developing advanced motor technologies, they have pioneered the development and implementation of DC Step Motors. By harnessing the power of these motors, [Company Name] has reshaped the manufacturing landscape, helping businesses enhance productivity and competitiveness.The key to the success of DC Step Motors lies in their unique design and functionality. These motors operate by dividing a complete rotation into a series of smaller steps. By precisely controlling these steps, manufacturers can achieve accurate and repeatable motion that is vital for many production processes. This level of precision ensures that components are positioned correctly, minimizing errors and providing consistent quality.One of the significant advantages of DC Step Motors is their ability to operate in an open-loop system, eliminating the need for costly and complex feedback devices. This simplicity reduces overall system costs while improving reliability. Additionally, these motors offer exceptional torque-to-size ratios, making them ideal for applications with limited space or weight constraints.The versatility of DC Step Motors is another aspect that sets them apart. With the ability to control speed, position, and torque accurately, manufacturers can tailor these motors to meet their specific requirements. Whether it be high-speed automation, accurate positioning, or fine-tuned torque control, DC Step Motors offer a robust and reliable solution.[Company Name] has been at the forefront of implementing DC Step Motors across various industries. Their commitment to research and development has resulted in continuous improvements in motor design, performance, and efficiency. Leveraging their technical expertise, [Company Name] has been able to customize the motors to suit diverse applications, meeting the unique needs of different businesses.The integration of DC Step Motors has not only streamlined manufacturing processes but also improved overall production efficiency. By automating tasks once performed manually, businesses can reduce labor costs, increase productivity, and enhance the overall quality of their output. This technology has led to a significant reduction in downtime, allowing companies to meet tight deadlines and delivery schedules consistently.Furthermore, the adoption of DC Step Motors has had a positive impact on the environment. These motors consume minimal energy, resulting in reduced power consumption and lower carbon emissions. By choosing this eco-friendly solution, manufacturers are not only contributing to a greener future but also enjoying long-term cost savings.In conclusion, DC Step Motors have undoubtedly revolutionized the manufacturing industry. Their unparalleled precision, versatility, and cost-effectiveness have transformed the way businesses operate, leading to increased productivity and profitability. With companies like [Company Name] pioneering their development and implementation, these motors are poised to continue reshaping the manufacturing landscape, driving innovation and growth for years to come.