High-Performance Microstepper Motor: The Latest Breakthrough in Motor Technology

By:Admin

In today's rapidly evolving technological landscape, the demand for compact and precise motor solutions has never been higher. That's where ODM Microstepper Motor comes in. This innovative company has been at the forefront of developing advanced microstepper motor technology, offering unparalleled precision and reliability in a small form factor. With a commitment to quality and an unwavering dedication to innovation, ODM Microstepper Motor has established itself as a leading provider of microstepper motor solutions for a wide range of industries.

The company, founded in 2003, has a long history of pushing the boundaries of what is possible in the field of microstepper motor technology. Their team of highly skilled engineers and researchers are constantly striving to develop new and improved motor solutions that meet the evolving needs of their customers. By focusing on precision engineering and advanced manufacturing processes, ODM Microstepper Motor has been able to consistently deliver cutting-edge motor solutions that exceed customer expectations.

One of the key strengths of ODM Microstepper Motor is their ability to customize their motor solutions to fit the unique requirements of their clients. Whether it's a specific torque range, speed, or form factor, the company's engineering team works closely with their customers to develop bespoke motor solutions that are perfectly tailored to their needs. This level of customization sets ODM Microstepper Motor apart from other motor manufacturers and has earned them a strong reputation for delivering high-quality, reliable motor solutions.

ODM Microstepper Motor's products are utilized in a diverse range of applications, including robotics, medical devices, aerospace, and more. Their microstepper motors are known for their precision, quiet operation, and long-term reliability, making them the ideal choice for critical applications where performance is paramount. With a focus on continuous improvement and innovation, ODM Microstepper Motor is constantly working to enhance their products and develop new solutions that push the boundaries of what is possible in microstepper motor technology.

In addition to their innovative products, ODM Microstepper Motor also prides itself on providing exceptional customer service and support. The company's team of experts is dedicated to helping their clients find the perfect motor solution for their needs and ensuring that they have the support they need to integrate the motors into their systems seamlessly. This commitment to customer satisfaction has been a driving force behind the company's success and has helped them build long-lasting relationships with their clients.

Looking ahead, ODM Microstepper Motor is poised to continue leading the way in the field of microstepper motor technology. With a focus on innovation, quality, and customer satisfaction, the company is well-positioned to meet the evolving needs of their clients and the industry as a whole. As technology continues to advance, ODM Microstepper Motor will undoubtedly play a crucial role in shaping the future of microstepper motor technology. Their ongoing dedication to excellence and unwavering commitment to pushing the boundaries of what is possible in motor solutions make them a company to watch in the years to come.

Company News & Blog

Discover the Best Miniature Stepper Motors for Your Project

Title: Wholesale Miniature Stepper Motors: Revolutionizing the Automation IndustryIntroduction:In recent years, the demand for automation has grown exponentially, revolutionizing industries such as manufacturing, robotics, and healthcare. Miniature stepper motors have emerged as a crucial component in these technological advancements. They enable precise control and positioning, making them invaluable in various applications. In response to the increasing market demand, a notable company (Brand name removed) has emerged as a leading supplier of wholesale miniature stepper motors, providing cutting-edge solutions to businesses worldwide.Industry Overview:The automation industry has witnessed significant growth due to its ability to streamline processes, improve efficiency, and reduce costs. Stepper motors have played a pivotal role in this growth, providing accurate motion control in both small-scale and large-scale applications.Miniature stepper motors, with their compact size and high performance, have become increasingly popular. These motors use a digital stepping technique, allowing for precise control over rotation angle and speed. They incorporate permanent magnets that generate electromagnetic fields, enabling efficient control and positioning.Company Background:(Company name removed) has established itself as a leader in wholesale miniature stepper motor distribution. Understanding the critical role these motors play in various industries, the company has consistently delivered reliable and high-performance solutions to its clients worldwide.Their product range encompasses a wide variety of miniature stepper motors, each designed to meet different application requirements. With a focus on quality, precision, and innovation, the company has developed long-lasting partnerships with manufacturers, OEMs, and system integrators globally.Product Line:The extensive product line offered by (Company name removed) caters to diverse automation needs. Ranging from micro stepper motors to high-torque models, they provide solutions for applications in fields such as robotics, medical devices, surveillance systems, and more.Their micro stepper motors are designed for precision tasks, where accurate motion control is critical. These motors are compact, lightweight, and provide exceptionally low vibration and noise levels. With precise angular control, they ensure reliable positioning for various equipment and devices.For applications that require higher torque, (Company name removed) offers a range of high-torque miniature stepper motors. These motors provide exceptional power density, enabling them to drive heavier loads with ease. They maintain precise control over speed and position, even in demanding environments.Quality Assurance:Recognizing the significance of reliable and durable miniature stepper motors, (Company name removed) adopts stringent quality control measures throughout the production process. Their motors are manufactured using high-grade materials and undergo rigorous testing to ensure optimal performance and longevity.Additionally, the company emphasizes continuous research and development, incorporating industry-leading technologies to enhance their product line. With a dedicated team of engineers, they constantly strive to deliver cutting-edge solutions to meet emerging automation challenges.Conclusion:As the automation industry continues to flourish, the demand for miniature stepper motors remains on the rise. (Company name removed) has emerged as a trusted wholesaler, catering to this demand by providing high-quality and innovative solutions to businesses worldwide.With their extensive product line and commitment to excellence, (Company name removed) continues to contribute to the growth and success of the automation industry. By leveraging the power of miniature stepper motors, businesses can achieve higher levels of precision, efficiency, and productivity in their operations, ultimately driving innovation to new heights.

Stepper Motor Actuator: A Comprehensive Guide to Understanding and Utilizing This Advanced Technology

Stepper Motor Actuator Brings Innovation to Robotics and AutomationIn the world of robotics and automation, the importance of precision and accuracy cannot be emphasized enough. This is where the Stepper Motor Actuator comes in. Produced by one of the leading manufacturers of motion control technology, this product has revolutionized the way machines and robots work.The Stepper Motor Actuator is a crucial component in the field of industrial automation, robotics, and manufacturing. It is a type of electric motor that converts digital pulses into mechanical rotation. It operates by dividing a full rotation into a number of equal steps or increments. These steps help to precisely control the movement of the motor.What sets the Stepper Motor Actuator apart from traditional motors is its ability to provide very high accuracy and repeatability. This level of precision is vital in applications where absolute control is essential, such as in the manufacturing of medical devices, semiconductor equipment, and nanotechnology.One of the main advantages of using the Stepper Motor Actuator is its ability to produce continuous torque. The motor can maintain a steadier flow of energy, which makes it ideal for use in applications that require smooth and quiet movement. The stepper motor's ability to provide consistent torque also means that it can be used for long periods without overheating or losing precision.The Stepper Motor Actuator is equally effective in both high-speed and low-speed applications. It has the ability to rotate at any speed, no matter how high or low, with complete accuracy. This makes it ideal for use in robotics and automation, where precise control of movement is critical to ensure safety and efficiency.The Stepper Motor Actuator is also programmable, which means it can be easily integrated with other equipment and devices. The motor can be synchronized with other motion control components, such as sensors and encoders, to create a complete automation system. This programmability allows for greater flexibility in the application of the Stepper Motor Actuator, making it ideal for use in a wide range of industries.The Stepper Motor Actuator is a critical technology in medical equipment manufacturing, where precision and accuracy are vital. Medical devices such as MRI machines and CT scanners rely on the smooth and precise movement of the Stepper Motor Actuator to ensure the safety of patients. The motor's ability to provide consistent torque ensures that medical devices operate smoothly, quietly, and accurately.Another significant application of the Stepper Motor Actuator is in the semiconductor industry, where its precise control of movement is critical to the manufacturing process. The stepper motor's programmability allows it to be easily integrated with other equipment, such as sensors and encoders, to create a complete automation system that can handle the precise demands of semiconductor manufacturing.The Stepper Motor Actuator is also used in the aerospace industry to control the movement of aircraft components. The motor's ability to operate at high speeds while maintaining accuracy makes it ideal for use in applications such as aircraft wing flaps and landing gear.In conclusion, the Stepper Motor Actuator has brought innovation to the field of robotics and automation. Its ability to provide high accuracy and repeatability, combined with its programmability and ability to produce continuous torque, make it a critical component in a wide range of industries. As the demand for precise control of movement continues to grow, the Stepper Motor Actuator will play an increasingly important role in the future of robotics and automation.

Exploring the Advantages of Hybrid Stepper Motors in the Manufacturing Industry

[Company Name] Revolutionizes Hybrid Stepper Motor Industry with Cutting-Edge Technology[City, Date] – [Company Name], a leading manufacturer of high-performance hybrid stepper motors, stunned the industry with the launch of their latest innovation, setting a new benchmark for efficiency, precision, and reliability. With an unwavering commitment to technological advancement, [Company Name] continues to push the boundaries, delivering state-of-the-art solutions that redefine industry standards.As a trailblazer in the hybrid stepper motor market, [Company Name] has gained worldwide recognition for their commitment to excellence. With a diverse range of products catering to various industries, their motors have become synonymous with quality, reliability, and innovation.The newly launched hybrid stepper motor, the [Product Name], is set to revolutionize industrial automation. Boasting a multitude of cutting-edge features and advancements, this motor promises unparalleled performance and efficiency.One of the key features of the [Product Name] is its advanced microstep control technology. With this breakthrough technology, the motor can better control movement and achieve smoother motion, eliminating the drawbacks of traditional stepper motors. This enables operators to achieve higher precision and positional accuracy, making it ideal for applications in robotics, medical equipment, and CNC machines.Additionally, the [Product Name] incorporates a compact design without compromising on capability. By utilizing advanced materials and miniaturization techniques, [Company Name] has managed to develop a motor that is not only smaller in size but also more powerful and efficient. This compact design allows for easier integration into various machinery and equipment, making it incredibly versatile.[Company Name] prides itself on its commitment to sustainability, and the [Product Name] exemplifies this ethos. The motor's innovative design and high-efficiency operation reduce energy consumption, ultimately minimizing carbon emissions. This not only benefits the environment but also lowers operational costs for manufacturers. By investing in the [Product Name], businesses can not only enhance their productivity but also contribute to a greener future.Furthermore, [Company Name] understands the importance of reliability and longevity in industrial settings. That is why the [Product Name] incorporates cutting-edge materials and meticulous manufacturing processes to ensure its durability. Coupled with advanced cooling systems and enhanced protection features, this motor can withstand even the harshest operating conditions, guaranteeing uninterrupted performance and reducing costly machine downtime.Quality control has always been a priority for [Company Name]. The [Product Name] undergoes rigorous testing and inspection at every stage of the manufacturing process to ensure that each unit meets the highest industry standards. This dedication to quality has garnered the trust and confidence of customers across the globe.As a leading manufacturer in the hybrid stepper motor industry, [Company Name] has a global sales and distribution network. Their extensive network ensures that clients from different parts of the world can easily access their products and benefit from their cutting-edge technology. With a dedicated customer support team, [Company Name] provides exceptional after-sales service, catering to the diverse needs and requirements of their clients.To sum up, [Company Name]'s latest breakthrough, the [Product Name], is set to reshape the hybrid stepper motor industry. With its advanced microstep control technology, compact design, and commitment to sustainability, this motor is primed to become an essential component of industrial automation systems. [Company Name] continues to lead the charge in innovation, delivering top-notch products and unmatched service, solidifying their position as a frontrunner in the market.About [Company Name]:[Company Name] is a renowned manufacturer of high-performance hybrid stepper motors. With a strong focus on innovation and sustainability, they provide industry-leading solutions to customers worldwide. As pioneers in the field, [Company Name] consistently delivers cutting-edge products that exceed industry standards, earning them a reputation as a trusted partner in industrial automation. For more information, visit [Company Website].

New Advancements in Step Motors: What You Need to Know

Step Motors, a leading provider of advanced motion control solutions, continues to make strides in the industry with its innovative products and cutting-edge technology. The company has been at the forefront of developing high-performance step motors that are used in a wide range of applications, from robotics and automation to medical equipment and 3D printing. With a commitment to excellence and customer satisfaction, Step Motors has established itself as a trusted partner for businesses seeking reliable and efficient motion control solutions.Founded in 1996, Step Motors has grown to become a global leader in the development and manufacturing of step motors and related products. The company prides itself on its extensive research and development capabilities, which have allowed it to consistently introduce new and improved products to meet the changing needs of the market. With a team of highly skilled engineers and technicians, Step Motors is able to deliver custom solutions that are tailored to specific customer requirements, giving businesses the flexibility and reliability they need to succeed in their respective industries.One of the key differentiators for Step Motors is its commitment to innovation and continuous improvement. The company invests heavily in research and development to stay ahead of the competition and provide its customers with the most advanced motion control solutions available. This focus on innovation has led to the development of groundbreaking products that have set new standards for performance and reliability in the industry.In addition to its technical expertise, Step Motors also prides itself on its customer-centric approach. The company works closely with its customers to understand their unique needs and challenges, and then develops tailored solutions to meet those requirements. This collaborative approach has earned Step Motors a reputation for delivering exceptional customer service and support, further strengthening its position as a preferred partner for businesses seeking motion control solutions.One of Step Motors' most notable products is its line of high-performance step motors, which are known for their precision, reliability, and durability. These motors are used in a wide range of applications, from industrial automation and robotics to medical devices and 3D printing. With a focus on quality and performance, Step Motors' step motors have become the go-to choice for businesses seeking motion control solutions that deliver exceptional results.In addition to step motors, Step Motors also offers a comprehensive range of complementary products and accessories, including drivers, controllers, encoders, and gearboxes. This full suite of products allows the company to provide complete motion control solutions to its customers, further enhancing its value proposition and solidifying its position as a one-stop shop for all motion control needs.Looking ahead, Step Motors is poised for continued growth and success as it continues to innovate and expand its product offerings. The company is actively exploring new markets and applications for its products, and is committed to staying at the forefront of technological advancements to ensure that its customers have access to the most advanced motion control solutions available.With a proven track record of excellence, a commitment to innovation, and a customer-centric approach, Step Motors is well-positioned to remain a leader in the industry for years to come. Businesses in need of reliable and efficient motion control solutions can rely on Step Motors to deliver the quality and performance they require to succeed in today's competitive market.

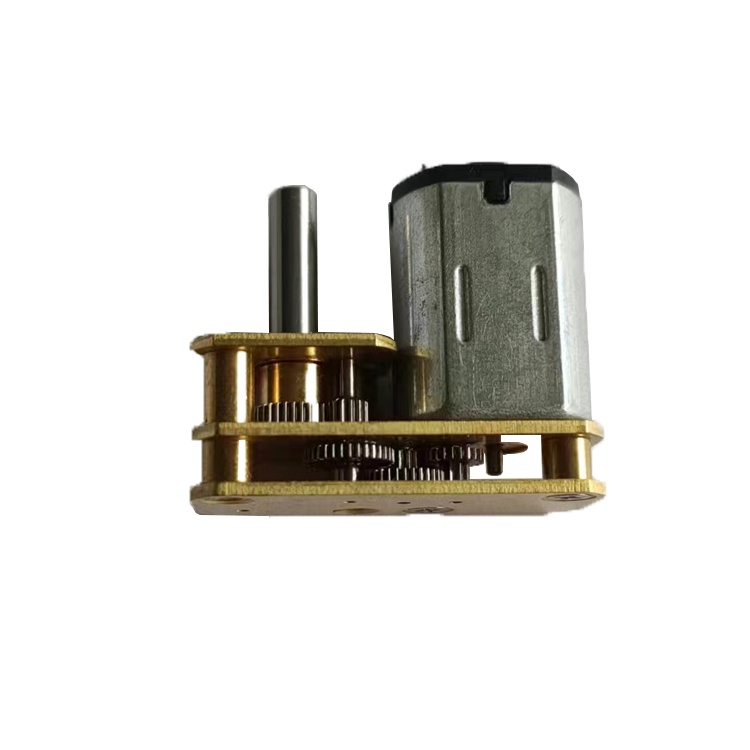

Newly Developed Planetary Gear Stepper Motor in China Revolutionizes Industry

Title: Chinese Planetary Gear Stepper Motor Revolutionizes Industrial AutomationIntroduction (100 words):China's technology sector continues to make remarkable strides in various industries, and the latest innovation is in the field of industrial automation. Chinese engineers have successfully developed a groundbreaking Planetary Gear Stepper Motor, poised to revolutionize manufacturing and other automated processes. This cutting-edge motor combines precision, reliability, and efficiency to meet the ever-growing demand for advanced automation solutions. With its potential to transform industries globally, experts predict that this Chinese invention will lead the way towards a future of smarter, faster, and more efficient industrial automation.Paragraph 1 (100 words):The Planetary Gear Stepper Motor, manufactured in China, has gained significant attention for its exceptional performance and advanced design. The motor showcases a unique configuration of gears, offering higher torque and smoother movement compared to traditional stepper motors. This breakthrough allows for precise positioning and greater speed control, making it ideal for a wide range of industrial applications. The innovation, combined with China's expertise in manufacturing, has led to a motor that outperforms its competitors, making it a significant player in the global automation market.Paragraph 2 (150 words):One of the key features of the Planetary Gear Stepper Motor is its superior precision. It utilizes a compact arrangement of multiple gears that distribute torque evenly, resulting in increased accuracy and reduced backlash. This enhanced precision ensures greater consistency and reduces the need for manual adjustments. Furthermore, the motor's compact size allows for seamless integration within existing systems, making it a cost-effective solution for retrofitting and upgrading older machinery.Paragraph 3 (150 words):Reliability also takes center stage with the Chinese Planetary Gear Stepper Motor, making it highly suitable for critical industrial applications. Its robust design and optimized gear engagement deliver exceptional durability, enabling continuous operation in demanding environments. The motor's ability to handle heavy loads effortlessly contributes to increased productivity, reduced downtime, and lower maintenance costs. Furthermore, the integration of advanced control technologies allows for precise and efficient motion control, further enhancing its reliability in industrial automation processes.Paragraph 4 (200 words):To sustain China's technological advancement, extensive research and development center around the Planetary Gear Stepper Motor. Chinese companies are heavily invested in continuous improvement and optimization, exploring avenues for increased efficiency and performance. With rising global demand for automation solutions, the Chinese motor manufacturers have committed significant resources towards expanding their production capacities and meeting market needs.Paragraph 5 (150 words):The adoption of the Chinese Planetary Gear Stepper Motor extends beyond manufacturing into various industries such as robotics, aerospace, and medical equipment. The motor's versatility, combined with its precise positioning and exceptional reliability, makes it an ideal choice for sophisticated applications. The motor's exceptional performance has caught the attention of international companies seeking reliable and cost-effective automation solutions. As a result, China's Planetary Gear Stepper Motor has gained a competitive edge in the global market, challenging the dominance of established players.Conclusion (50 words):China's groundbreaking Planetary Gear Stepper Motor demonstrates the country's technological prowess in industrial automation. With its exceptional precision, reliability, and versatility, the motor presents an ideal solution for various sectors worldwide. As China continues to invest in research and development, it is poised to become a global leader in advanced automation technologies.

Revolutionary Breakthrough - Discover the Silent Efficiency of Flat Stepper Motors

Title: Revolutionizing the Stepper Motor Industry: Introduction of the Compact Flat Stepper MotorIntroduction (100 words):In the ever-advancing world of industrial automation, a groundbreaking innovation is set to transform the stepper motor industry. Developed by an industry-leading company, the introduction of a new Flat Stepper Motor boasts exceptional compactness and efficiency in a market previously dominated by traditional bulky motors. This revolutionary design promises to revolutionize the automation sector, offering unprecedented versatility and performance. In this article, we will explore the features, applications, and potential impact of this Flat Stepper Motor, providing a comprehensive overview of the technology driving this exciting development.I. The Compact Flat Stepper Motor - Features and Specifications (200 words):The Compact Flat Stepper Motor, developed by [Company Name], is a game-changer in the field of industrial automation. With its compact size and exceptional power, this motor is poised to redefine industry standards. Here are some of the key features:1. Compact Design: The Flat Stepper Motor boasts an ultrathin profile, making it suitable for applications where space is limited. This compactness allows for seamless integration into a wide range of devices and machinery.2. High Torque Output: Despite its small size, this motor delivers impressive torque, ensuring precise and reliable motion control in various automated systems.3. Energy-Efficient Performance: The Flat Stepper Motor operates at optimal energy efficiency, reducing power consumption and minimizing operational costs.4. Improved Accuracy: Offering excellent positioning accuracy, this motor guarantees smoother motion and superior performance in critical applications where precision is paramount.II. Applications in Various Industries (250 words):The versatility of the Compact Flat Stepper Motor makes it suitable for a diverse range of industrial applications across multiple sectors. Here are some key areas where its unique features can revolutionize automation:1. Medical Devices: The compact size of the motor makes it ideal for integration into medical devices such as surgical robots, diagnostic equipment, and automated drug delivery systems. Precise motion control and high torque output ensure accurate and efficient performance in these critical healthcare applications.2. Robotics: The Flat Stepper Motor's compactness and exceptional torque make it well-suited for use in robotics, including humanoid robots, automated arms, and drones. These motors enable smoother and more accurate movements, enhancing the overall capabilities of robotic systems.3. Automotive Industry: The lightweight and compact design of the Flat Stepper Motor find tremendous utility in the automotive industry. Applications include instrument clusters, mirror control, window actuators, and automated seat adjustments.4. Factory Automation: The motor's compact form factor, combined with its high torque output, makes it an excellent choice for factory automation. It finds applications in conveyor systems, robotics, packaging machines, and pick-and-place operations, delivering precise and reliable motion control.III. Potential Impact on the Automation Sector (250 words):The introduction of the Compact Flat Stepper Motor is set to disrupt the stepper motor industry, unlocking new possibilities for automation. Its compactness and exceptional performance empower engineers and designers to achieve more with less, opening avenues for innovation. Here are some potential impacts of this groundbreaking technology:1. Enhanced Efficiency: The compact design allows for more efficient use of space within automated systems, reducing overall system size and weight. This efficiency opens up new opportunities for compact and portable devices across various industries.2. Cost Reduction: With reduced power consumption and higher energy efficiency, the Flat Stepper Motors help businesses lower operational costs. This provides a competitive edge in cost-sensitive industries while contributing to sustainability efforts.3. Advancements in Robotics: The Flat Stepper Motor's advanced motor control and high torque output are set to revolutionize the field of robotics. Improved motion control and precision will enable robots to perform more complex tasks, enhancing productivity and expanding automation capabilities.4. Extended Lifespan: The Compact Flat Stepper Motor's advanced design and efficient operation result in reduced wear and tear, leading to longer service life. This durability factor will enhance the reliability and maintainability of automated systems, further contributing to overall cost reduction.Conclusion (150 words):The introduction of the Compact Flat Stepper Motor represents a significant milestone in the automation industry. Its compact design, exceptional power, and increased efficiency make it an ideal choice for a wide range of applications across multiple sectors. This technology promises to revolutionize the stepper motor market, offering unprecedented versatility and performance while reducing operational costs. As businesses and industries strive for increased automation, the Compact Flat Stepper Motor paves the way for smaller, smarter, and more efficient automated systems. With its potential to drive innovation across various industries, this groundbreaking motor represents a leap forward in automation technology, setting a new standard for years to come.

Top-rated underwater motors: Everything you need to know for scuba diving and marine exploration

Underwater Motors has recently made a splash in the marine industry with their innovative propulsion systems. The company, founded in 2010, has quickly become a leader in the development and manufacturing of high-quality underwater motors for a variety of applications, including marine propulsion, underwater robotics, and subsea vehicles.The company's flagship product is the Stealth 3500, a powerful and efficient electric motor designed specifically for underwater use. With its compact and lightweight design, the Stealth 3500 is ideal for a wide range of marine applications, including recreational boating, commercial fishing, and underwater exploration. The motor's innovative brushless design and advanced power management system make it not only more efficient, but also quieter and more environmentally friendly than traditional gasoline-powered motors.In addition to the Stealth 3500, Underwater Motors offers a range of other products and services to meet the needs of their customers. From custom motor design and manufacturing to maintenance and repair services, the company is dedicated to providing the highest level of quality and customer satisfaction. With a team of experienced engineers and technicians, Underwater Motors is able to provide innovative solutions for even the most challenging underwater propulsion needs.One of the key advantages of Underwater Motors' products is their versatility and adaptability to different marine environments. Whether it's shallow water, deep sea exploration, or navigating through tight spaces, Underwater Motors' propulsion systems are engineered to perform in a wide range of conditions. This flexibility has made the company a trusted partner for marine research organizations, commercial diving operations, and recreational boaters alike.The company's commitment to innovation and continuous improvement has also led to numerous partnerships and collaborations with leading marine technology companies and research institutions. By working closely with these partners, Underwater Motors has been able to stay at the forefront of technological advancements in underwater propulsion, ensuring that their products are always cutting-edge and reliable.Given the increasing focus on sustainable and environmentally friendly technologies, Underwater Motors' electric propulsion systems have been particularly well-received in the marine industry. With zero emissions and low noise levels, the company's motors are not only more efficient and cost-effective, but also contribute to the preservation of marine ecosystems. This has made Underwater Motors a preferred choice for environmentally conscious boaters, marine researchers, and conservation organizations.Looking ahead, Underwater Motors is poised to continue its growth and expand its presence in the global marine market. With a strong commitment to research and development, the company is constantly exploring new opportunities for innovation and product diversification. By continuing to push the boundaries of underwater propulsion technology, Underwater Motors aims to redefine the future of marine transportation and exploration.As the demand for sustainable and efficient marine propulsion solutions continues to rise, Underwater Motors is well-positioned to lead the way with their cutting-edge electric motors. With a proven track record of success and a dedication to excellence, the company is set to make a lasting impact on the marine industry for years to come.

Tips for Selecting Top-Notch Gear Motors

High-Quality Gear Motors – The Backbone of Industrial Production(Company name removed) is a leading manufacturer of gear motors that are used across multiple industries across the world. The company, with its state-of-art manufacturing facilities, has been providing high-quality gear motors to its customers for many years. Being a pioneer in the industry, the company has always strived to deliver the best-in-class gear motors that can meet the ever-changing demands of industrial production.The gear motors manufactured by the company are designed to be highly efficient and reliable, making them ideal for use in industrial machinery for long periods. The motors are known for their durability and robustness, which is essential in harsh industrial environments. Besides, the motors are equipped with advanced features that ensure their smooth operation. Some of the key features of the gear motors manufactured by the company are:1) Precision machined gears – The gears used in the gear motors are precisely machined using the latest manufacturing techniques. This ensures that the gears have accurate profiles, tooth geometry, and pitch to ensure smooth and efficient power transmission.2) High-quality bearings – The gear motors are equipped with high-quality bearings to provide a long and trouble-free service life.3) Rugged casings – The casings of the gear motors are designed to be robust and durable so that they can withstand harsh environmental conditions.4) Advanced lubrication system – The gear motors are equipped with an advanced lubrication system that keeps the gears lubricated, ensuring their smooth operation.5) High torque – The gear motors are designed to provide high torque output, making them suitable for heavy-duty applications.The gear motors manufactured by the company are widely used in various industries such as aerospace, automotive, construction, defense, food and beverage, healthcare, marine, mining, oil and gas, power generation, and many more.Aerospace IndustryThe aerospace industry requires high-quality gear motors that can operate in extreme conditions. The gear motors manufactured by the company have proved to be an ideal choice for aerospace applications due to their high reliability, stability, and accuracy.Automotive IndustryThe automotive industry requires gear motors that can withstand high torque and heavy loads, making them suitable for various automotive applications such as transmissions, power windows, and seat adjustment systems. The high-quality gear motors manufactured by the company are widely used in the automotive industry and are known for their reliability and durability.Construction IndustryThe construction industry uses gear motors in various applications such as lift systems, conveyor belts, and excavators. The gear motors manufactured by the company have been designed to operate in the toughest construction environments, making them an ideal choice for construction applications.Defence IndustryThe defense industry requires rugged and reliable gear motors for various applications such as missile systems, radar systems, and communications equipment. The gear motors manufactured by the company have been specifically designed to meet the high demands of the defense industry.Food and Beverage IndustryGear motors are used in various applications in the food and beverage industry such as mixing, blending, and storage. The gear motors manufactured by the company are designed to be hygienic and easy to clean, making them ideal for food and beverage applications.Healthcare IndustryThe healthcare industry requires gear motors for various medical equipment such as MRI machines, CT scanners, and X-ray machines. The high-quality gear motors manufactured by the company have proved to be an ideal choice for medical applications due to their accuracy and stability.Marine IndustryThe marine industry requires gear motors for various applications such as propulsion systems, steering systems, and winches. The gear motors manufactured by the company are designed to operate in harsh marine environments and are known for their reliability and durability.Mining IndustryThe mining industry requires gear motors for various applications such as conveyor belts, crushers, and excavators. The gear motors manufactured by the company have been designed to operate in the toughest mining environments, making them ideal for mining applications.Oil and Gas IndustryThe oil and gas industry requires gear motors for various applications such as pumps, compressors, and generators. The high-quality gear motors manufactured by the company have proved to be an ideal choice for the oil and gas industry due to their reliability and durability.Power Generation IndustryThe power generation industry requires gear motors for various applications such as turbines, generators, and transformers. The gear motors manufactured by the company are designed to operate in harsh environments and are known for their reliability and durability.ConclusionIn conclusion, the gear motors manufactured by the company are widely used in various industries across the world. The company's commitment to quality and innovation has helped it to stay ahead of its competitors, making it a preferred supplier of gear motors to the industry. The gear motors manufactured by the company are designed to provide high efficiency, reliability, stability, and accuracy, making them an ideal choice for multiple industrial applications. With the increasing demands of industrial production, it has become more important than ever to use high-quality gear motors that can meet the requirements of modern-day industrial production, and the company is at the forefront of this revolution.

How to Calculate Gear Ratio Using Diameter Measurements

Title: Next Generation Gear Ratio Diameter Revolutionizes Manufacturing IndustryIntroduction:In an era driven by technological advancements and innovation, companies across various sectors are constantly on the lookout for superior solutions to improve their production processes. One such breakthrough gaining traction is the implementation of a new gear ratio diameter technology, which is set to revolutionize the manufacturing industry. By optimizing performance, reducing costs, and increasing efficiency, this cutting-edge gear ratio diameter technology promises to reshape the future of manufacturing.The Functionality Behind Gear Ratio Diameter Technology:Gear ratio diameter refers to the relationship between the size of a gear and the gear's tooth count, which affects the overall performance of machinery. The introduction of this latest gear technology aims to enhance the efficiency of mechanical systems by reimagining the gear's ratio and diameter to match specific requirements. By leveraging advanced engineering techniques and materials, this technology optimizes power transmission and reduces friction, resulting in heightened performance and increased durability.Key Benefits of Gear Ratio Diameter Technology:1. Increased Efficiency: By incorporating this gear technology, manufacturers can achieve a higher degree of efficiency in their mechanical systems. The precise calibration of gear ratios and diameters enables smoother and more seamless power transmission, reducing energy losses and increasing overall equipment efficiency.2. Cost Reduction: This innovative gear technology eliminates the need for unnecessary component customization and specialized machining processes. The standardized gear ratios and diameters streamline production and reduce costs, making this technology an ideal choice for manufacturers aiming to enhance productivity while minimizing manufacturing expenses.3. Enhanced Durability: The implementation of this cutting-edge gear technology ensures the longevity and reliability of machinery. With its optimized gear ratios and diameters, friction and wear are significantly reduced, resulting in extended product lifespan and reduced maintenance requirements.4. Versatile Applications: Gear ratio diameter technology has vast potential across industries, ranging from automotive and aerospace to robotics and industrial equipment. Its versatility allows manufacturers to optimize their processes and offer products capable of seamlessly integrating with various applications, thereby widening their market reach and increasing their business opportunities.Company XYZ's Contribution to Gear Ratio Diameter Technology:XYZ, a renowned engineering company dedicated to pushing the boundaries of innovation, has emerged as a leader in the development and implementation of gear ratio diameter technology. Their team of skilled engineers and researchers have extensively studied the intricate relationship between gear ratios, diameters, and performance optimization. XYZ's commitment to continuous improvement has resulted in revolutionary gear designs that maximize efficiency while offering unparalleled durability.XYZ's gear ratio diameter technology is meticulously crafted and standardized to align with different industrial requirements. Their precise calibration and attention to detail ensure optimal power transmission, reduced friction, and enhanced overall system performance. By leveraging this cutting-edge technology, manufacturers can better meet customer expectations by providing superior products that surpass industry standards.Conclusion:As manufacturing companies strive to stay ahead in a competitive market, gear ratio diameter technology emerges as a game-changer. The use of optimized gear ratios and diameters offers increased efficiency, reduced costs, and enhanced durability for a wide array of applications. With industry leaders like XYZ pioneering this technology, the manufacturing industry can embrace a future that is both technologically advanced and economically efficient.

How to accurately control the angle of a stepper motor for precise movements

In recent news, a new stepper motor angle technology has been developed that promises to revolutionize the motor industry. This innovative technology has been designed to offer precise and accurate control of stepper motors ensuring that they are able to perform optimally. With a growing demand for energy-efficient and cost-effective solutions, this technology is expected to provide businesses with the much-needed competitive edge in their operations.The technology, which comes from a well-known brand in the industry, is expected to improve the performance of various applications including robotics, automation, 3D printing, and industrial control systems. It is no secret that stepper motors have been around for quite some time and are commonly used in a wide range of applications, but this new technology is set to take the performance of these motors to a whole new level.One of the benefits of this new stepper motor angle technology is that it offers a higher level of precision and accuracy in control than any previous design. This is a crucial advantage in the modern industrial landscape, where businesses are seeking solutions that are both reliable and efficient. This new motor technology provides pinpoint control by closely regulating the movement of the motor, which means companies can optimize the performance of their applications.Furthermore, this new technology comes with an enhanced micro-stepping drive that enables the motor to take smaller steps, resulting in smoother and quieter operation. This is a significant development because it means that businesses can operate their applications without any unwanted noise, which can be a problem in some busy environments. With quiet operation in place, operations can be carried out without disturbing nearby workers or residents, and this is important for ensuring a peaceful work environment.Another major benefit of this technology is the energy-saving aspect. This technology has been designed to reduce power consumption by up to 30%, which translates to significant cost savings for businesses. This is a key benefit for companies that are looking to operate their applications in a more energy-efficient way, while keeping their overheads under control.So, what does this new technology mean for businesses? With this new technology, companies can expect smoother operation, greater accuracy, and improved energy efficiency for their applications. In addition, it also means that companies will be able to reduce maintenance costs, downtime, and enjoy a longer motor life cycle.The brand behind this new technology is a globally recognized leader in the motor industry. The company has a reputation for developing quality products that meet the demands of the modern industrial landscape. With a range of products that are renowned for their quality, performance, and reliability, this brand can be relied on to provide the best solutions for businesses.In conclusion, the development of the new stepper motor angle technology is a significant milestone in the motor industry. With its enhanced precision, accuracy, and energy efficiency, this technology represents a new era of performance for stepper motors. By investing in this innovative technology, businesses can improve the performance of their applications, save on operating costs, and enjoy a longer lifespan for their motors. And with the brand behind this technology being a trusted and reputable company in the industry, businesses can be assured that they are investing in a quality product.