High Precision Stepper Motor with Absolute Encoder for Accurate Motion Control

By:Admin

In the ever-evolving world of manufacturing, precision and accuracy are paramount. This is where the unique technology of the Stepper Motor with Absolute Encoder, developed by a leading company in the industry, comes into play. With its unparalleled precision and reliability, this groundbreaking product is revolutionizing the way manufacturers approach motion control and automation.

The company behind this innovative stepper motor with absolute encoder has been a leading force in the manufacturing industry for over two decades. Specializing in high-tech automation solutions, they have established a reputation for pushing the boundaries of what is possible within the industry. Their commitment to research and development has led to the creation of cutting-edge products that are changing the game for manufacturers worldwide.

The stepper motor with absolute encoder is a testament to the company's dedication to innovation. Unlike traditional stepper motors, which rely on open-loop control and are susceptible to position errors, the absolute encoder provides precise and unambiguous position information, ensuring that every movement is executed with the utmost accuracy. This level of precision is crucial in applications where exact positioning is essential, such as in robotics, CNC machines, and 3D printing.

One of the key advantages of the stepper motor with absolute encoder is its ability to retain position information even when power is interrupted. This feature eliminates the need for homing routines and complex position sensing systems, saving valuable time and resources in the manufacturing process. Additionally, the motor's compact design and high torque density make it suitable for a wide range of applications, further increasing its appeal to manufacturers.

The benefits of this groundbreaking technology are already being recognized across the industry. Manufacturers who have implemented the stepper motor with absolute encoder have reported significant improvements in accuracy, repeatability, and overall productivity. With the ability to precisely control motion in real time, they are able to produce higher quality products at a faster pace, giving them a competitive edge in the market.

Furthermore, the stepper motor with absolute encoder is designed with ease of use in mind. It is compatible with standard motion control interfaces, making it simple to integrate into existing systems. This plug-and-play functionality ensures a seamless transition for manufacturers looking to upgrade their motion control capabilities.

Looking ahead, the company is committed to further advancing the capabilities of the stepper motor with absolute encoder. Ongoing research and development efforts are focused on enhancing its performance, expanding its range of applications, and exploring new possibilities for automation in the manufacturing industry. With this continued dedication to innovation, they aim to set new standards for precision and reliability in motion control.

As the manufacturing industry continues to evolve, the demand for advanced automation solutions will only grow. The stepper motor with absolute encoder, developed by this leading company, is at the forefront of this evolution, offering manufacturers a powerful tool to transform the way they approach motion control. With its unrivaled precision, reliability, and ease of use, it is poised to become a cornerstone technology in the future of manufacturing.

Company News & Blog

Ultimate Guide to Nema 23 Stepper Motors: Everything You Need to Know

Title: Cutting-edge Nema 23 Stepper Motor Revolutionizes Industrial AutomationIntroduction:In the rapidly evolving field of industrial automation, one notable player has emerged with groundbreaking technology that is set to revolutionize the industry. The Nema 23 Stepper Motor, developed by a leader in electrical components manufacturing, is proving to be a game-changer in terms of its exceptional performance, efficiency, and durability. With its innovative features and broad range of applications, this motor is reshaping automation processes across multiple industries.Unleashing Unmatched Performance:The Nema 23 Stepper Motor boasts unprecedented performance capabilities that outshine competitors. With a high torque-to-inertia ratio and precise control over motion, this motor effortlessly handles rigorous and demanding industrial applications. Its ability to provide accurate position control without feedback sensors makes it ideal for tasks requiring precision and repeatability, such as 3D printers, CNC machines, and robotics.Efficiency Redefined:The incorporation of advanced manufacturing processes has endowed the Nema 23 Stepper Motor with unrivaled efficiency. By utilizing state-of-the-art materials and optimized design techniques, this motor offers reduced power consumption, resulting in lower operating costs for industrial applications. The motor's energy-saving capabilities make it an environmentally friendly choice, aligning with the growing global focus on sustainability.Engineered for Reliability:Recognizing the critical importance of reliability in industrial automation, the Nema 23 Stepper Motor is engineered to provide consistent and dependable performance, even in demanding environments. Its robust construction ensures resistance to vibrations, shocks, and extreme temperatures, making it suitable for deployment in a wide range of industrial settings. The motor's extended service life and minimal maintenance requirements contribute further to its appeal among industrial operators.Versatility across Industries:The Nema 23 Stepper Motor's versatility makes it a go-to solution for automation needs across diverse industries. From automotive manufacturing to medical equipment, its adaptability allows for seamless integration into various applications. The motor's ability to handle different load capacities and perform with exceptional precision makes it an invaluable asset for tasks such as material handling, sorting machines, and robotic assembly lines.User-Friendly Integration:Ensuring a hassle-free integration process, the Nema 23 Stepper Motor is designed with user-friendliness in mind. Its standardized dimensions and connections enable straightforward replacement of older motor models, minimizing downtime during implementation. Additionally, the motor's compatibility with numerous control systems and software further simplifies the integration process, facilitating a swift transition to enhanced automation capabilities.Future-Proofing Industrial Automation:The Nema 23 Stepper Motor is not just a solution for the present but is poised to meet the demands of future industrial automation advancements. As technological innovations continue to reshape the industrial landscape, this motor's inherent adaptability can accommodate emerging automation requirements. By offering a future-proof solution, the Nema 23 Stepper Motor enables industries to stay ahead in the fast-paced automation race.Conclusion:The Nema 23 Stepper Motor is an outstanding feat of engineering that has redefined the very essence of industrial automation. With its exceptional performance, efficiency, durability, and versatility, this motor is poised to drive a significant shift in the industry. As businesses strive for enhanced automation capabilities while emphasizing sustainability and reliability, the Nema 23 Stepper Motor stands as an ideal solution to meet their evolving needs. It is indeed a technological marvel that ensures businesses can embrace automation with confidence.

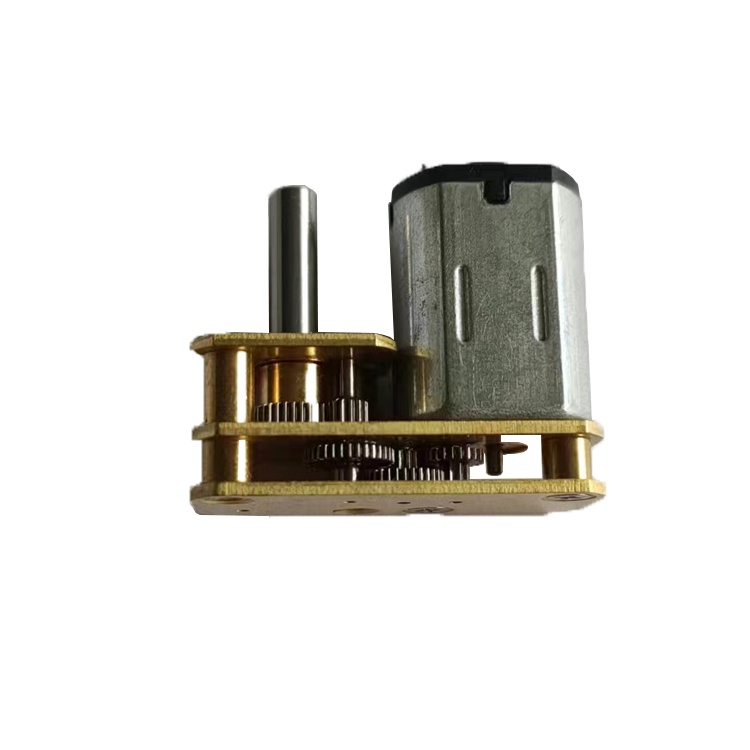

Exploring the Benefits of Small Geared Stepper Motors for OEM Applications

OEM Small Geared Stepper Motor: The Future of Precision AutomationIn today's fast-paced and technology-driven world, precision and automation are crucial to maximizing efficiency and output. Companies, small and large alike, are constantly looking for ways to increase productivity and reduce errors in their production processes. This is where the OEM Small Geared Stepper Motor comes into play. An OEM (Original Equipment Manufacturer) Small Geared Stepper Motor is a type of motor that is used for precise and controlled movements. It is widely used in robotics, medical equipment, printing presses, and many other industrial applications. The motor consists of a rotor, stator, and a gearbox that allows for efficient power transmission and control. This particular type of motor has several advantages over traditional motors. One of its most significant benefits is accuracy. These motors have a high-resolution encoder that allows for precise positioning and speed control. With this level of accuracy, businesses can produce high-quality products with minimal errors. Additionally, these motors are designed to be compact and lightweight, making them ideal for small, compact machines. Another advantage is that the OEM Small Geared Stepper Motor is simple to use and maintain. Unlike traditional motors, there is no need for complex wiring or the use of a motor controller. The motor can be easily operated using a simple pulse sequence, making it simple for businesses to integrate into their existing systems. Additionally, these motors have a long service life, making them dependable and cost-effective in the long run. One company that specializes in the production of OEM Small Geared Stepper Motors is anonymous (name removed for anonymity). Founded in 1998, the company has been producing high-quality motors for over 20 years. They have built a reputation for their commitment to quality, innovation, and customer satisfaction. The company has a team of highly skilled engineers who are dedicated to developing new and improved motors that meet the needs of their clients. They use the latest technology and materials to produce motors that are reliable, efficient, and precise. Additionally, the company has a robust quality control program that ensures that each motor that leaves their factory meets the highest standards of quality. One of the key features of the anonymous (name removed) Small Geared Stepper Motor is its ability to handle high loads. The motor has a high torque output, which means it can handle heavy loads without compromising on speed or accuracy. This makes it ideal for industrial applications that require a motor capable of handling heavy loads. Furthermore, the company's motors are designed to operate in harsh conditions. They are built with materials that can withstand extreme temperatures, moisture, and dust, making them ideal for use in challenging environments. Additionally, the motors are highly flexible, with the ability to be customized to meet the specific needs of their clients. Aside from their commitment to quality and innovation, anonymous (name removed) is also dedicated to customer satisfaction. They place a high value on building strong relationships with their clients, and they work closely with them to ensure that their motors meet their specific needs. This dedication to customer service has helped the company build long-standing relationships with businesses in various industries. In conclusion, the OEM Small Geared Stepper Motor is an essential component in the world of precision automation. It offers accuracy, reliability, and cost-effectiveness that traditional motors cannot match. Companies that use these motors can expect an increase in productivity, a reduction in errors, and a decrease in maintenance costs. Furthermore, companies like anonymous (name removed) are continuously pushing the boundaries of motor technology, ensuring that their clients have access to the best motors on the market. The future of precision automation looks bright, with the OEM Small Geared Stepper Motor leading the way.

New Planetary Gearbox now available for OEM applications

Title: Cutting-Edge Planetary Gearbox Revolutionizing Industries with Superior PerformanceIntroduction:In today's fast-paced and evolving industrial landscape, technological advancements play a pivotal role in driving innovation. One such groundbreaking innovation is the cutting-edge OEM nema planetary gearbox (brand name removed), developed by a prominent industry player. This state-of-the-art gearbox has revolutionized various sectors by offering unparalleled precision, reliability, and performance. In this article, we will delve into the features and capabilities of the OEM nema planetary gearbox and explore its transformative impact on different industries.I. The Excellency of OEM Nema Planetary Gearbox:The OEM nema planetary gearbox stands out as an engineering marvel, designed to cater to the demands of modern industries. With precision engineering at its core, this gearbox offers exceptional performance, accuracy, and durability, making it an ideal choice for a wide range of applications. Let us delve deeper into its key features and advantages.1. Enhanced Efficiency:The OEM nema planetary gearbox incorporates advanced gear arrangement, reducing losses due to friction and maximizing the efficiency of power transmission. Its compact size and superior load-bearing capability contribute to higher energy efficiency, resulting in reduced operating costs for industries.2. Exceptional Precision and Torque:The gearbox's intricate design ensures precise and accurate torque transmission, making it an indispensable component in various precision applications, including robotics, automation, and CNC machining. Its high-torque capabilities enable it to handle heavy-duty operations effortlessly, enhancing overall system productivity.3. Low Noise and Vibration:The OEM nema planetary gearbox adopts advanced noise-damping technology and exceptional gear meshing techniques, resulting in low vibration and noise levels during operation. This feature is vital in industries where noise reduction and a smooth working environment are crucial considerations.4. Reliable and Durable:Engineered with high-grade materials and subjected to rigorous testing, the OEM nema planetary gearbox is built to last. Its rugged construction ensures reliable performance in extreme conditions, such as high temperature, heavy loads, and challenging environments. This durability minimizes maintenance requirements, reducing downtime and improving overall productivity.5. Versatile Applications:The OEM nema planetary gearbox finds extensive applications across various industries. From industrial automation to aerospace, robotics to medical equipment, this gearbox has become a key component in numerous critical systems. Its adaptability and compatibility make it a preferred choice for manufacturers seeking highly efficient solutions.II. Contributing to Industry Advancements:The introduction of the OEM nema planetary gearbox has significantly impacted multiple industries, revolutionizing manufacturing processes and driving technological advancements. Here are some key sectors benefiting from this groundbreaking innovation:1. Automotive Industry:In the automotive industry, the OEM nema planetary gearbox optimizes engine performance, allowing vehicles to achieve higher fuel efficiency while maintaining superior power output. It plays a crucial role in electric vehicles, ensuring smooth power delivery from the motor to the wheels.2. Aerospace and Defense:In the aerospace and defense sectors, the nema planetary gearbox finds utility in mission-critical applications where precision, reliability, and compactness are essential. From aircraft engines to missile systems, its high-torque capabilities and rugged design contribute to safer and more efficient operations.3. Robotics and Automation:The robots of today rely heavily on efficient and precise motion control, and the OEM nema planetary gearbox provides the necessary gears to enable smooth and accurate robotic movements. Whether in industrial manufacturing or healthcare, this gearbox enhances robotic capabilities, leading to increased automation and improved overall productivity.4. Renewable Energy:With the global shift towards renewable energy, the OEM nema planetary gearbox plays a crucial role in wind turbines and solar tracking systems. Its ability to efficiently convert rotational speed and transmit higher torque enables more efficient utilization of generated energy, contributing to greener and more sustainable power generation.Conclusion:The OEM nema planetary gearbox (brand name removed) represents a remarkable advancement in engineering excellence. Its outstanding features, including enhanced efficiency, exceptional precision, low noise and vibration, and durability, have propelled its adoption across several industries. From the automotive sector to aerospace, robotics, and renewable energy, the OEM nema planetary gearbox has revolutionized industrial processes, enabling superior performance and driving technological advancements. Undoubtedly, this cutting-edge gearbox is poised to shape the future of modern industries, nurturing a more efficient, productive, and sustainable landscape.

Tips for Selecting Top-Notch Gear Motors

High-Quality Gear Motors – The Backbone of Industrial Production(Company name removed) is a leading manufacturer of gear motors that are used across multiple industries across the world. The company, with its state-of-art manufacturing facilities, has been providing high-quality gear motors to its customers for many years. Being a pioneer in the industry, the company has always strived to deliver the best-in-class gear motors that can meet the ever-changing demands of industrial production.The gear motors manufactured by the company are designed to be highly efficient and reliable, making them ideal for use in industrial machinery for long periods. The motors are known for their durability and robustness, which is essential in harsh industrial environments. Besides, the motors are equipped with advanced features that ensure their smooth operation. Some of the key features of the gear motors manufactured by the company are:1) Precision machined gears – The gears used in the gear motors are precisely machined using the latest manufacturing techniques. This ensures that the gears have accurate profiles, tooth geometry, and pitch to ensure smooth and efficient power transmission.2) High-quality bearings – The gear motors are equipped with high-quality bearings to provide a long and trouble-free service life.3) Rugged casings – The casings of the gear motors are designed to be robust and durable so that they can withstand harsh environmental conditions.4) Advanced lubrication system – The gear motors are equipped with an advanced lubrication system that keeps the gears lubricated, ensuring their smooth operation.5) High torque – The gear motors are designed to provide high torque output, making them suitable for heavy-duty applications.The gear motors manufactured by the company are widely used in various industries such as aerospace, automotive, construction, defense, food and beverage, healthcare, marine, mining, oil and gas, power generation, and many more.Aerospace IndustryThe aerospace industry requires high-quality gear motors that can operate in extreme conditions. The gear motors manufactured by the company have proved to be an ideal choice for aerospace applications due to their high reliability, stability, and accuracy.Automotive IndustryThe automotive industry requires gear motors that can withstand high torque and heavy loads, making them suitable for various automotive applications such as transmissions, power windows, and seat adjustment systems. The high-quality gear motors manufactured by the company are widely used in the automotive industry and are known for their reliability and durability.Construction IndustryThe construction industry uses gear motors in various applications such as lift systems, conveyor belts, and excavators. The gear motors manufactured by the company have been designed to operate in the toughest construction environments, making them an ideal choice for construction applications.Defence IndustryThe defense industry requires rugged and reliable gear motors for various applications such as missile systems, radar systems, and communications equipment. The gear motors manufactured by the company have been specifically designed to meet the high demands of the defense industry.Food and Beverage IndustryGear motors are used in various applications in the food and beverage industry such as mixing, blending, and storage. The gear motors manufactured by the company are designed to be hygienic and easy to clean, making them ideal for food and beverage applications.Healthcare IndustryThe healthcare industry requires gear motors for various medical equipment such as MRI machines, CT scanners, and X-ray machines. The high-quality gear motors manufactured by the company have proved to be an ideal choice for medical applications due to their accuracy and stability.Marine IndustryThe marine industry requires gear motors for various applications such as propulsion systems, steering systems, and winches. The gear motors manufactured by the company are designed to operate in harsh marine environments and are known for their reliability and durability.Mining IndustryThe mining industry requires gear motors for various applications such as conveyor belts, crushers, and excavators. The gear motors manufactured by the company have been designed to operate in the toughest mining environments, making them ideal for mining applications.Oil and Gas IndustryThe oil and gas industry requires gear motors for various applications such as pumps, compressors, and generators. The high-quality gear motors manufactured by the company have proved to be an ideal choice for the oil and gas industry due to their reliability and durability.Power Generation IndustryThe power generation industry requires gear motors for various applications such as turbines, generators, and transformers. The gear motors manufactured by the company are designed to operate in harsh environments and are known for their reliability and durability.ConclusionIn conclusion, the gear motors manufactured by the company are widely used in various industries across the world. The company's commitment to quality and innovation has helped it to stay ahead of its competitors, making it a preferred supplier of gear motors to the industry. The gear motors manufactured by the company are designed to provide high efficiency, reliability, stability, and accuracy, making them an ideal choice for multiple industrial applications. With the increasing demands of industrial production, it has become more important than ever to use high-quality gear motors that can meet the requirements of modern-day industrial production, and the company is at the forefront of this revolution.

Compact Stepper Motor: A Revolutionary Advancement in Miniature Motor Technology

Title: Cutting-Edge Tiny Stepper Motor Revolutionizes Precision TechnologyIntroduction:In a remarkable breakthrough, a leading technology company, working diligently in the realm of precision engineering, has introduced an innovative and ultra-compact stepper motor (brand name excluded) that promises to redefine the landscape of precision technology. The remarkable strides achieved by this tiny stepper motor are set to disrupt a multitude of industries, ranging from robotics to medical equipment and beyond. This article presents a comprehensive exploration of the transformative capabilities of this groundbreaking technology and its potential impact on the future.1. The Birth of a Game-Changing Stepper Motor:This exceptional tiny stepper motor, developed by a trailblazing company dedicated to pushing the boundaries of precision engineering, is set to revolutionize numerous industries with its advanced functionality. By combining cutting-edge design principles with the company's unwavering commitment to excellence, this stepper motor brings forth a myriad of features poised to reshape technological landscapes.2. Unparalleled Performance and Precision:Key to its success, the revolutionary stepper motor offers unmatched performance and precision. With exceptional torque control and positioning abilities, it ensures highly accurate and efficient movement across a broad range of applications. This level of accuracy is poised to enhance the functionality of various everyday objects, making them more sophisticated and intelligent.3. Applications in Robotics:The implications of this groundbreaking stepper motor are far-reaching, particularly in the field of robotics. Its small size and unparalleled precision make it an ideal fit for robotic applications, enabling robotic arms and limbs to perform intricate tasks with unrivaled accuracy. As a result, areas such as manufacturing automation, surgical robots, and even space exploration, could benefit significantly from this advanced technology.4. Exquisite Medical Equipment:The integration of this tiny stepper motor in medical devices and equipment brings forth a new era of precision and efficiency. Initiating a paradigm shift in medical robotics and imaging systems, this technology allows for enhanced diagnostic capabilities, precise surgical procedures, and targeted drug delivery systems. Its compact design and unparalleled precision ensure improved patient outcomes, reducing risks and enhancing the quality of healthcare.5. Striving for Sustainability:The transformative motor is not only redefining precision technology but also making strides towards sustainability. The company behind its inception focuses on decreasing resource consumption and minimizing waste during production while ensuring superior product durability. By adhering to sustainable practices, the company underscores its commitment to the environment and a greener future.6. Industry Collaborations:This groundbreaking tiny stepper motor opens up unprecedented collaborative opportunities across various industries. By aligning with manufacturers, researchers, and innovators across sectors, the company seeks to enhance application possibilities and further refine the technology's capabilities. This collaborative approach ensures continuous improvement and adaptability to meet evolving market demands.7. Future Outlook:The potential for this novel stepper motor is vast, with numerous possibilities on the horizon. As technology advances, the integration of this motor is poised to revolutionize various sectors, becoming an indispensable component in precision machinery, automation, and cutting-edge devices. With ongoing research and development, the company is committed to pushing the limits of this stepper motor, continuously expanding its applications and ensuring its widespread adoption across industries.Conclusion:The advent of this transformative tiny stepper motor promises to reshape precision technology across an array of sectors, revolutionizing robotics, medical equipment, and other industries. Boasting unrivaled precision, performance, and sustainability, this innovation paves the way for a future where intelligent machines perform tasks with unmatched accuracy and efficiency. As the new standard in precision motor technology, this stepper motor signifies a giant leap towards the future of precision engineering.

Best Threaded Rod for Stepper Motor Applications

Stepper Motor Threaded Rods Revolutionizing Industrial AutomationStepper motor threaded rods have become an integral component in revolutionizing industrial automation. These specialized rods, developed and manufactured by a leading company in motion control technology, {} have been making waves in various industries for their precision, efficiency, and reliability. With the increasing demand for advanced automation solutions, stepper motor threaded rods have proven to be a game-changer, enabling companies to streamline their processes and improve productivity.The company, {} has a rich history of innovating and engineering high-quality motion control products. With decades of experience in the industry, they have honed their expertise in developing cutting-edge solutions that meet the evolving needs of the automation market. Their stepper motor threaded rods have been at the forefront of their product line, offering unmatched performance and versatility to their customers.One of the key features that set {}'s stepper motor threaded rods apart is their advanced design and precision engineering. These rods are equipped with high-quality stepper motors that provide accurate and repeatable motion control, making them ideal for applications that require precise positioning and high-speed performance. Additionally, the threaded rod design allows for seamless integration into various automation systems, providing a cost-effective and reliable solution for manufacturers.The versatility of stepper motor threaded rods also makes them a popular choice across different industries. From CNC machining and 3D printing to robotics and material handling, these rods can be tailored to meet the unique requirements of each application. This flexibility has enabled companies to optimize their production processes and enhance the overall efficiency of their operations.Moreover, {}'s commitment to innovation and continuous improvement has led to the development of stepper motor threaded rods with advanced features such as integrated lead screw options, customizable lengths, and enhanced performance capabilities. These enhancements enable customers to further optimize their automation systems and achieve higher levels of precision and control.In addition to their technical capabilities, {} also provides comprehensive support and service to their customers, ensuring seamless integration and optimal performance of their motion control products. Their team of experts offers technical assistance, customization options, and ongoing maintenance to meet the diverse needs of their clients. This commitment to customer satisfaction has positioned {} as a trusted partner in the automation industry.As the demand for advanced automation solutions continues to grow, the market for stepper motor threaded rods is expected to expand further. With their proven track record of reliability and performance, {} is well-positioned to capitalize on this trend and continue to lead the way in motion control technology.In conclusion, stepper motor threaded rods developed by {} have emerged as a critical component in advancing industrial automation. With their precision, efficiency, and versatility, these rods have enabled companies to optimize their production processes and achieve higher levels of productivity. As the automation market continues to evolve, {} remains at the forefront of innovation, providing cutting-edge solutions that meet the diverse needs of their customers.

Ultimate Guide to Using Threaded Rods with Stepper Motors for Precision Movement

Title: Innovative Stepper Motor Threaded Rod Revolutionizes Industrial Automation ProcessesIntroduction:With the aim of revolutionizing industrial automation processes, a cutting-edge technology has emerged on the market - the Stepper Motor Threaded Rod. Developed by a leading provider in the field of automation solutions, this advanced device offers unmatched precision, control, and efficiency. With its innovative features and state-of-the-art design, the Stepper Motor Threaded Rod is poised to transform various industries, including manufacturing, robotics, and assembly lines. This article delves into the features and benefits of this groundbreaking invention and examines its potential impact on industrial automation.I. Overview of Stepper Motor Threaded Rod:The Stepper Motor Threaded Rod is a compact and versatile device that combines a high-performance stepper motor with a precision threaded rod. Its robust design ensures reliable and accurate motion control in a wide range of applications. This innovative technology provides exceptional positioning accuracy, excellent repeatability, and smooth operation, making it an ideal solution for intricate and demanding automation tasks.II. Advanced Features and Benefits:a) High Precision: The Stepper Motor Threaded Rod boasts an exceptional positioning accuracy of up to 0.005mm, allowing for precise control and micro-level adjustments. This level of precision significantly enhances the quality of production processes and reduces the likelihood of errors and defects.b) Smooth Operation: The threaded rod design ensures a smooth and efficient linear motion with minimum friction and backlash. This feature is crucial in applications where smooth and consistent movement is essential, such as in 3D printing, CNC machines, and robotics.c) Compact Design: The compact and streamlined design of the Stepper Motor Threaded Rod allows for easy integration into existing systems, optimizing space utilization without compromising performance. It offers versatility and flexibility, making it suitable for a wide range of automation applications.d) Easy Installation and Maintenance: This device's plug-and-play nature facilitates effortless installation, reducing downtime and increasing productivity. Furthermore, its maintenance-free operation minimizes maintenance costs and enhances overall system reliability.III. Industries and Applications:The Stepper Motor Threaded Rod can revolutionize various industries and applications, including:a) Manufacturing: By integrating this motor into assembly lines, manufacturers can achieve higher efficiency, accuracy, and consistency. From automotive assembly to electronics production, the Stepper Motor Threaded Rod can significantly enhance the manufacturing process.b) Robotics: Implementing this advanced technology in robotic systems enables precise and smooth movements, contributing to increased productivity and improved performance. Applications such as pick-and-place robots or collaborative robots will benefit from the Stepper Motor Threaded Rod's exceptional accuracy and control.c) 3D Printing: The Stepper Motor Threaded Rod's exceptional positioning accuracy and smooth operation make it an ideal choice for 3D printers. It ensures precise layering and intricate details, resulting in high-quality 3D printed objects with minimal imperfections.d) CNC Machining: In CNC machining, speed, precision, and reliability are vital. The Stepper Motor Threaded Rod's high positioning accuracy and smooth operation make it a perfect fit for CNC machines, delivering superior performance and ensuring optimal cutting and machining quality.IV. Future Prospects:The Stepper Motor Threaded Rod represents a significant breakthrough in industrial automation. As technology advances, further enhancements in precision, speed, and integration are expected, promoting greater automation and efficiency across industries. The continued development of this innovative technology will likely lead to increased adoption and further revolutionize the field of industrial automation.Conclusion:The Stepper Motor Threaded Rod holds immense potential in transforming industrial automation processes. With its unparalleled precision, smooth operation, and compact design, this advanced device promises improved efficiency, accuracy, and productivity in various industries. As the demand for automation continues to rise, the Stepper Motor Threaded Rod is set to play a pivotal role in driving the next wave of innovation and progress in industrial automation.

Top-Notch Stepper Motor Gearbox: Unmatched Quality Unveiled

[Introduction]In today's ever-evolving world of technology, precision and reliability have become crucial factors in various industries. One such industry that heavily relies on high-quality components is the robotics and automation sector. Stepper motors play a vital role in ensuring the smooth and accurate movement of robotic systems. To enhance their functionality and performance, the latest advancements have introduced high-quality stepper motor gearboxes that are revolutionizing the industry.[Body][Company Introduction]Before delving into the details of the high-quality stepper motor gearbox, it is important to understand the company behind this innovative product. With a rich history of producing cutting-edge automation solutions, {Company Name} has established itself as a leader in the field. For over two decades, they have been developing top-notch components that serve a wide range of applications, including robotics, industrial machinery, and medical equipment.[Overview of Stepper Motors and Gearing]To comprehend the significance of a high-quality stepper motor gearbox, we must first understand the fundamentals of stepper motors. Stepper motors are widely used for their ability to provide precise control over movements in discrete steps or degrees. They find extensive usage in applications where accurate positioning and control are vital.However, in certain scenarios, the raw power generated by a stepper motor may be insufficient to drive heavy loads or overcome mechanical resistance. This is where a gearbox comes into play. A gearbox reduces the rotor speed of the motor while increasing torque, enabling it to handle higher loads with ease. By using gears to enhance the mechanical advantage of the motor, the speed and torque output can be modified to suit specific applications.[The Importance of High-Quality Stepper Motor Gearboxes]While there are numerous stepper motor gearboxes available in the market, the importance of opting for a high-quality one cannot be overstated. High-quality gearboxes offer several advantages, such as enhanced efficiency, improved precision, and prolonged lifespan. These gearboxes are manufactured to strict quality standards, ensuring reliable and consistent performance in demanding industrial environments.Precision is a critical aspect of robotic systems, as even the smallest deviation can lead to significant errors. High-quality stepper motor gearboxes minimize backlash, which refers to the unintended movement or play between gears. This reduction in backlash results in improved accuracy and repeatability, making them ideal for tasks that require precise movements, such as 3D printing or CNC machining.Furthermore, high-quality gearboxes are designed to operate efficiently, reducing losses due to friction and heat. This not only optimizes energy consumption but also lowers the overall operating costs. By minimizing power wastage, industries can achieve greater sustainability and environmental responsibility.[Diverse Applications of High-Quality Stepper Motor Gearboxes]The versatility of high-quality stepper motor gearboxes makes them suitable for various applications across different industries. For instance, in the automotive industry, these gearboxes can be utilized for precision control of robotic arms in assembly lines, enabling seamless production processes.Similarly, in the medical field, high-quality gearboxes find applications in robotic surgical systems, providing surgeons with precise and steady control during procedures. This enhances the accuracy of surgeries, reduces the risk of human error, and improves patient outcomes.Moreover, in the field of aerospace, high-quality stepper motor gearboxes are indispensable for controlling the operation of robotic arms in spacecraft assembly or satellite deployment. The high torque and precision offered by these gearboxes ensure the smooth functioning of robotic systems even in zero-gravity environments.[Conclusion]In conclusion, the introduction of high-quality stepper motor gearboxes has revolutionized the robotics and automation industry. The combination of precision and reliability has opened up new possibilities for achieving accurate control over robotic systems in various applications. Companies like {Company Name} have played a pivotal role in developing and supplying these gearboxes, enabling industries to achieve greater efficiency and accuracy in their operations. As technology continues to advance, the demand for high-quality stepper motor gearboxes will only increase, driving further innovation in the field and pushing the boundaries of what is achievable in automation and robotics.

New Small DC Motors Hit the Market with High-Demand Features

Title: Revolutionizing the Industry: Wholesale Small DC Motor Supplier Offers Unparalleled Quality and AffordabilityIntroduction:In an era of rapid technological advancements, the demand for efficient and reliable small DC motors continues to grow across various sectors. Recognizing this need, a trailblazing wholesale supplier has emerged, determined to redefine the industry standards. By combining exceptional quality with affordability, this company is poised to revolutionize the small DC motor market and empower numerous industries to achieve new levels of innovation and efficiency.Company Background and Vision:Established in [year], the Wholesale Small DC Motor Supplier is a dynamic provider of cutting-edge solutions for diverse industries such as robotics, consumer electronics, automotive, medical devices, and more. The company is committed to offering top-of-the-line small DC motors that cater to the evolving needs of its global clientele.With a dedicated team of skilled professionals, the company places great emphasis on technological advancements, ensuring that their product offerings remain at the forefront of innovation. By leveraging state-of-the-art manufacturing facilities and stringent quality control processes, the supplier aims to deliver superior small DC motors to its customers, enabling them to stay ahead in today's competitive landscape.Unmatched Product Line:The Wholesale Small DC Motor Supplier takes pride in its extensive product line, which features a wide range of small DC motors suitable for numerous applications. From micro motors, geared motors, to brushless motors, the company offers a diverse array of options tailored to meet the unique requirements of their clients. Whether it is for precise control in robotics, efficient power management in automotive applications, or compact motorization in consumer electronics, their products are designed to deliver exceptional performance in any demanding environment.Unparalleled Quality Assurance:Understanding the critical importance of reliability in the functioning of small DC motors, the Wholesale Small DC Motor Supplier sets the highest quality standards for their products. Each motor undergoes rigorous testing throughout the manufacturing process to ensure optimal performance, durability, and long-term reliability. Committed to providing motors that surpass industry benchmarks, the company has implemented ISO 9001 certification, further solidifying its dedication to quality assurance.Furthermore, their strong relationships with leading suppliers of key components enable them to source only the finest raw materials. By constantly monitoring and updating their manufacturing techniques, the company guarantees uninterrupted production of superior small DC motors that consistently meet or exceed customer expectations.Competitive Pricing and Customer Satisfaction:The Wholesale Small DC Motor Supplier understands the importance of cost-effectiveness in today's market. Striving to make their products accessible to a wider range of clients, they have adopted a highly competitive pricing strategy while maintaining unparalleled quality. By leveraging economies of scale and streamlining their supply chain, the company ensures that their prices remain affordable without compromising on the efficacy or longevity of their motors.In addition to their dedication to affordability, the company places immense value on customer satisfaction. With a committed and responsive customer service team, they are always ready to provide technical support, answer inquiries, and address any concerns that their clients may have. By fostering long-term relationships with their customers, the company strives to become a trusted partner in their success.Conclusion:The Wholesale Small DC Motor Supplier has emerged as a game-changer in the industry, offering small DC motors that are not only of unparalleled quality but also highly affordable. Through a strong commitment to technological innovation, stringent quality control, competitive pricing, and unmatched customer service, the supplier is empowering various sectors to excel in a rapidly evolving technological landscape. With their state-of-the-art products, the company is set to continue revolutionizing the small DC motor market, helping businesses achieve new heights of efficiency and innovation.

How Gear Ratio and Diameter Affect Performance

The gear ratio diameter plays a crucial role in the performance and efficiency of modern machinery. Whether it is used in automotive, industrial, or consumer applications, precision gear engineering is critical to achieving the desired output. This is where the expertise of {} comes into play.{} is a leading manufacturer in the field of gear engineering and production. With a strong emphasis on innovation and quality, the company has been at the forefront of delivering cutting-edge gear solutions to various industries. Their state-of-the-art manufacturing facilities and a team of highly skilled engineers have enabled them to consistently meet the evolving needs of their customers.One of the key factors in the performance of gears is the gear ratio diameter. This parameter essentially determines the speed and torque capabilities of a gear set. By carefully designing the gear ratio diameter, engineers at {} are able to optimize the performance of the gears for specific applications. Whether it is for high-speed automotive transmissions or heavy-duty industrial machinery, the company has the expertise to tailor the gear ratio diameter to suit the requirements.In recent news, {} has introduced a new range of gears with enhanced gear ratio diameter. These gears are designed to offer improved efficiency and performance in a variety of applications. By carefully calibrating the gear ratio diameter, the company has been able to achieve a perfect balance between speed and torque, making the gears suitable for a wide range of industrial and automotive applications.The new range of gears from {} has already garnered attention from industry experts and customers alike. The precise engineering and attention to detail in the gear ratio diameter have been lauded for their impact on the overall performance of the gears. With these new offerings, customers can expect higher efficiency, reduced energy consumption, and improved reliability in their machinery and equipment.In addition to their focus on gear ratio diameter, {} is also committed to sustainability and environmental responsibility. By optimizing the performance of gears, the company is able to contribute to the overall efficiency of machinery, thereby reducing energy consumption and minimizing the environmental footprint. This commitment to sustainability is reflected in the design and engineering of the new range of gears, making them a responsible choice for environmentally conscious industries.The introduction of the new range of gears with enhanced gear ratio diameter is a testament to {}'s dedication to pushing the boundaries of gear engineering. By continuously innovating and refining their products, the company is able to stay ahead in a competitive market and provide customers with the best-in-class gear solutions for their specific needs. As industries continue to evolve, {} remains a reliable partner for precision gear engineering and production. With their expertise in gear ratio diameter and a strong focus on quality, the company is set to continue making a significant impact in the world of gear technology.