High-Quality Stepper Motor for Original Equipment Manufacturer

By:Admin

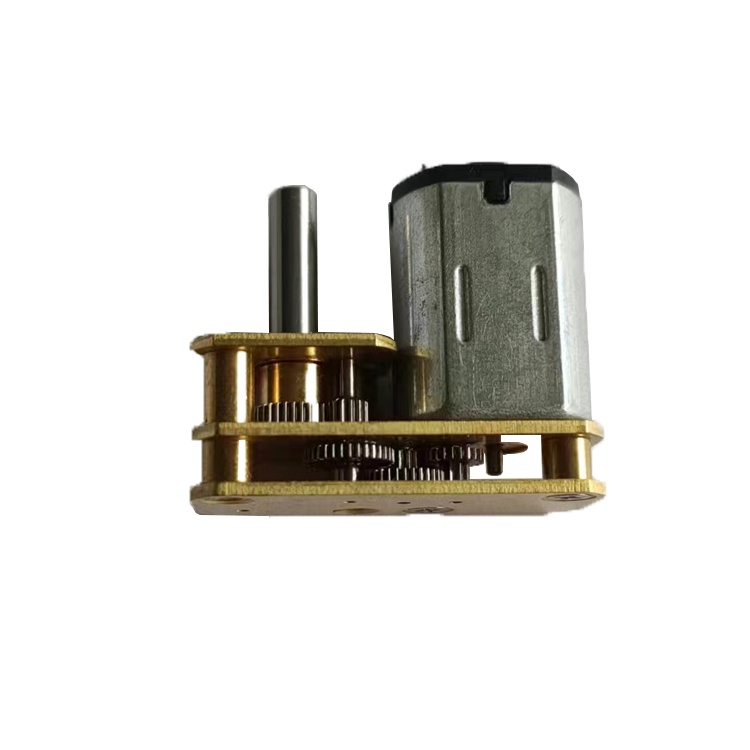

The world of motion control technology has seen significant advancements in recent years, and one standout innovation is the OEM Stepper Motor. This powerful and reliable motor is designed to provide precise and efficient movement control in a wide range of industrial applications.

The OEM Stepper Motor is the brainchild of a leading manufacturer in the motion control industry. With a strong commitment to research and development, this company has been at the forefront of developing cutting-edge solutions for motion control challenges. The OEM Stepper Motor represents the culmination of years of expertise and innovation, offering a high-performance motor that is tailored to meet the demands of modern industrial automation.

One of the key features of the OEM Stepper Motor is its superior precision and accuracy. This motor is capable of delivering highly precise movement control, making it ideal for applications that require exact positioning and motion control. Whether it's in CNC machines, 3D printers, or automated manufacturing systems, the OEM Stepper Motor provides the level of accuracy and reliability that today's industries demand.

In addition to its precision, the OEM Stepper Motor is also known for its exceptional durability and robustness. Built to withstand the rigors of industrial environments, this motor is designed to deliver consistent performance even in the most demanding conditions. With a rugged construction and high-quality components, the OEM Stepper Motor offers a level of reliability that ensures uninterrupted operation and minimal downtime.

Another standout feature of the OEM Stepper Motor is its versatility. This motor is available in a wide range of configurations, including varying step angles, torque levels, and size options. This versatility allows the OEM Stepper Motor to be tailored to specific application requirements, ensuring that it can deliver the exact performance needed for a particular motion control task.

Furthermore, the OEM Stepper Motor is designed for ease of integration and compatibility with existing motion control systems. With a range of connectivity options and compatibility with standard control interfaces, this motor can be seamlessly integrated into a variety of industrial automation setups. This makes it a convenient and practical choice for manufacturers and system integrators looking to upgrade their motion control capabilities.

The OEM Stepper Motor is also designed with energy efficiency in mind. By leveraging advanced motor control technologies, this motor is able to achieve high levels of efficiency and reduce energy consumption. This not only helps to lower operational costs but also aligns with the growing emphasis on sustainability and environmental responsibility in the industry.

With its superior performance, durability, versatility, and energy efficiency, the OEM Stepper Motor has quickly garnered attention in the motion control market. Manufacturers across various industries are recognizing the value of this motor in enhancing the precision and reliability of their motion control systems.

As the demand for advanced motion control solutions continues to grow, the OEM Stepper Motor is poised to play a pivotal role in shaping the future of industrial automation. With its innovative design and unmatched performance, this motor represents a significant step forward in motion control technology.

In conclusion, the OEM Stepper Motor stands as a testament to the relentless pursuit of innovation and excellence in the motion control industry. With its precision, durability, versatility, and energy efficiency, this motor is well-positioned to meet the evolving needs of modern industrial automation. As manufacturers and system integrators seek to optimize their motion control capabilities, the OEM Stepper Motor offers a compelling solution that combines performance and reliability in a single, powerful package.

Company News & Blog

Powerful High Torque DC Motor for Industrial Applications

High Torque DC Motor Revolutionizes the IndustryThe use of High Torque DC Motors has been a game-changer for many industries, and one company leading the way in this technology is {company name}. With their innovative designs and cutting-edge technology, {company name} has quickly become a leading provider of high torque DC motors for a wide range of applications.{Company Name} has been at the forefront of motor technology for decades, constantly evolving and innovating to meet the changing needs of the industry. With a focus on quality, reliability, and performance, their high torque DC motors have become the go-to choice for many companies that require high-performance motors for their applications.One of the key features of {company name}'s high torque DC motors is their ability to deliver high torque at low speeds, making them ideal for applications where power and precision are essential. This unique capability has made these motors a go-to choice for industries such as robotics, automation, and automotive, where precise control and high torque are critical.In addition to their high torque capabilities, {company name}'s DC motors are also known for their efficiency and reliability. Utilizing advanced designs and materials, these motors are able to deliver high performance while also being energy-efficient, making them a cost-effective choice for companies looking to reduce their energy consumption.{Company name} offers a wide range of high torque DC motors to suit the specific needs of their customers. From small, compact motors for use in robotics and automation, to larger, more powerful motors for industrial applications, they have a motor to fit virtually any requirement.One recent example of the impact of {company name}'s high torque DC motors is in the field of electric vehicles. As the demand for electric vehicles continues to grow, so does the need for high-performance motors that can deliver the power and efficiency required for these vehicles to perform at their best. {Company name} has been at the forefront of this market, providing high torque DC motors that are helping to drive the electric vehicle revolution.With their commitment to innovation and excellence, {company name} continues to push the boundaries of what is possible with high torque DC motors. Their dedication to quality and performance has earned them a reputation as a trusted and reliable provider of high torque DC motors, and they are poised to continue leading the way in this industry for years to come.As the demand for high torque DC motors continues to grow across a wide range of industries, {company name} is well-positioned to meet this demand with their cutting-edge technology and commitment to excellence. With a focus on quality, reliability, and performance, {company name}'s high torque DC motors are revolutionizing the industry and setting new standards for what is possible with motor technology.

Powerful High Torque DC Motor: The Ultimate Guide

[HIGH TORQUE DC MOTOR] company, a leading manufacturer of high-quality DC motors, has recently unveiled its latest innovation in the form of a high torque DC motor. With a strong focus on research and development, [HIGH TORQUE DC MOTOR] has consistently delivered cutting-edge products that meet the evolving needs of various industries.The new high torque DC motor is designed to provide superior performance and efficiency, making it an ideal choice for a wide range of applications. Whether it's powering industrial machinery, robotics, or electric vehicles, this motor is engineered to deliver reliable and consistent torque output, ensuring smooth and stable operation.One of the key features of the high torque DC motor is its robust construction, which enhances its durability and longevity. The motor is built to withstand the rigors of demanding environments, making it a reliable choice for industrial and commercial use. Additionally, [HIGH TORQUE DC MOTOR] has integrated advanced thermal management systems into the motor, ensuring that it can operate at peak performance levels without overheating.Furthermore, the high torque DC motor is equipped with a range of customizable options, allowing customers to tailor the motor to their specific requirements. From different shaft configurations to varying speed and torque specifications, [HIGH TORQUE DC MOTOR] offers versatility and flexibility to meet diverse application needs.In addition to its technical capabilities, [HIGH TORQUE DC MOTOR] is committed to sustainability and environmental responsibility. The high torque DC motor is designed to be energy-efficient, helping businesses reduce their carbon footprint and operating costs. This aligns with [HIGH TORQUE DC MOTOR]'s dedication to supporting green initiatives and promoting eco-friendly solutions within the industry.With a strong emphasis on quality assurance, [HIGH TORQUE DC MOTOR] conducts rigorous testing and inspection processes to ensure that every motor meets the highest standards of performance and reliability. This dedication to quality has earned [HIGH TORQUE DC MOTOR] a reputation for delivering products that exceed customer expectations and set new benchmarks within the industry.The unveiling of the high torque DC motor underscores [HIGH TORQUE DC MOTOR]'s continuous commitment to innovation and technological advancement. By leveraging years of expertise and experience in motor design and engineering, the company has once again raised the bar with its latest offering."We are thrilled to introduce our new high torque DC motor to the market," said the spokesperson for [HIGH TORQUE DC MOTOR]. "This motor represents a significant leap forward in terms of performance, efficiency, and versatility. It is a testament to our relentless pursuit of excellence and our commitment to providing our customers with the best possible solutions."As [HIGH TORQUE DC MOTOR] continues to expand its product portfolio, the company remains focused on staying at the forefront of the industry. By investing in research, development, and innovation, [HIGH TORQUE DC MOTOR] aims to address the evolving needs of its customers and anticipate future trends in the market.For businesses and organizations seeking a reliable and high-performance DC motor solution, [HIGH TORQUE DC MOTOR] offers a compelling option with its new high torque DC motor. With its superior engineering, customizable features, and dedication to quality, the motor is poised to make a significant impact across various sectors.

High-quality micro stepper motor lead screw for OEM applications

OEM Micro Stepper Motor Lead Screw: The Future of Precision TechnologyIn today's fast-paced world, precision and accuracy are more important than ever. From manufacturing to medical equipment, industries rely on cutting-edge technology to ensure the highest level of precision in their products. This is where the OEM micro stepper motor lead screw comes in. With its advanced design and unparalleled precision, this innovative technology is changing the game for industries that demand top-quality products.The OEM micro stepper motor lead screw is a crucial part of the company's product line. With its exceptional precision and advanced design, the lead screw is revolutionizing the way industries approach precision technology. By providing a seamless and efficient motion control solution, the lead screw is pushing the boundaries of what is possible in precision engineering.One of the key features of the OEM micro stepper motor lead screw is its compact size. This allows for seamless integration into a wide range of applications, from medical equipment to robotics. The lead screw's small size does not compromise its capabilities, as it is capable of delivering precise and reliable performance in even the most demanding of environments.Another standout feature of the OEM micro stepper motor lead screw is its unparalleled precision. With its advanced design and high-quality construction, the lead screw offers unparalleled accuracy, ensuring that industries can rely on it for the most precise motion control applications. This level of precision is essential for industries that require the highest level of accuracy, such as aerospace, automotive, and medical equipment manufacturing.The lead screw's advanced design also sets it apart from other precision motion control solutions. With its high torque capacity and low backlash, the lead screw offers a level of reliability that is unmatched in the industry. This means that industries can trust the lead screw to deliver consistent and precise performance, even in the most challenging of conditions.The OEM micro stepper motor lead screw is also designed with versatility in mind. With its wide range of available sizes and configurations, the lead screw can be tailored to meet the specific needs of any industry. This level of customization ensures that industries can rely on the lead screw for a wide range of applications, from small-scale precision instruments to large-scale industrial machinery.In addition to its advanced design and precision capabilities, the OEM micro stepper motor lead screw is also backed by a company with a long-standing reputation for excellence in precision engineering. With a proven track record of delivering high-quality motion control solutions, the company behind the lead screw is a trusted partner for industries that demand the highest level of performance.The future of precision technology is here, and it is powered by the OEM micro stepper motor lead screw. With its advanced design, unparalleled precision, and unmatched reliability, the lead screw is changing the game for industries that demand the highest level of accuracy in their products. As industries continue to push the boundaries of what is possible in precision engineering, the OEM micro stepper motor lead screw will undoubtedly play a crucial role in shaping the future of precision technology.

Tips for Selecting Top-Notch Gear Motors

High-Quality Gear Motors – The Backbone of Industrial Production(Company name removed) is a leading manufacturer of gear motors that are used across multiple industries across the world. The company, with its state-of-art manufacturing facilities, has been providing high-quality gear motors to its customers for many years. Being a pioneer in the industry, the company has always strived to deliver the best-in-class gear motors that can meet the ever-changing demands of industrial production.The gear motors manufactured by the company are designed to be highly efficient and reliable, making them ideal for use in industrial machinery for long periods. The motors are known for their durability and robustness, which is essential in harsh industrial environments. Besides, the motors are equipped with advanced features that ensure their smooth operation. Some of the key features of the gear motors manufactured by the company are:1) Precision machined gears – The gears used in the gear motors are precisely machined using the latest manufacturing techniques. This ensures that the gears have accurate profiles, tooth geometry, and pitch to ensure smooth and efficient power transmission.2) High-quality bearings – The gear motors are equipped with high-quality bearings to provide a long and trouble-free service life.3) Rugged casings – The casings of the gear motors are designed to be robust and durable so that they can withstand harsh environmental conditions.4) Advanced lubrication system – The gear motors are equipped with an advanced lubrication system that keeps the gears lubricated, ensuring their smooth operation.5) High torque – The gear motors are designed to provide high torque output, making them suitable for heavy-duty applications.The gear motors manufactured by the company are widely used in various industries such as aerospace, automotive, construction, defense, food and beverage, healthcare, marine, mining, oil and gas, power generation, and many more.Aerospace IndustryThe aerospace industry requires high-quality gear motors that can operate in extreme conditions. The gear motors manufactured by the company have proved to be an ideal choice for aerospace applications due to their high reliability, stability, and accuracy.Automotive IndustryThe automotive industry requires gear motors that can withstand high torque and heavy loads, making them suitable for various automotive applications such as transmissions, power windows, and seat adjustment systems. The high-quality gear motors manufactured by the company are widely used in the automotive industry and are known for their reliability and durability.Construction IndustryThe construction industry uses gear motors in various applications such as lift systems, conveyor belts, and excavators. The gear motors manufactured by the company have been designed to operate in the toughest construction environments, making them an ideal choice for construction applications.Defence IndustryThe defense industry requires rugged and reliable gear motors for various applications such as missile systems, radar systems, and communications equipment. The gear motors manufactured by the company have been specifically designed to meet the high demands of the defense industry.Food and Beverage IndustryGear motors are used in various applications in the food and beverage industry such as mixing, blending, and storage. The gear motors manufactured by the company are designed to be hygienic and easy to clean, making them ideal for food and beverage applications.Healthcare IndustryThe healthcare industry requires gear motors for various medical equipment such as MRI machines, CT scanners, and X-ray machines. The high-quality gear motors manufactured by the company have proved to be an ideal choice for medical applications due to their accuracy and stability.Marine IndustryThe marine industry requires gear motors for various applications such as propulsion systems, steering systems, and winches. The gear motors manufactured by the company are designed to operate in harsh marine environments and are known for their reliability and durability.Mining IndustryThe mining industry requires gear motors for various applications such as conveyor belts, crushers, and excavators. The gear motors manufactured by the company have been designed to operate in the toughest mining environments, making them ideal for mining applications.Oil and Gas IndustryThe oil and gas industry requires gear motors for various applications such as pumps, compressors, and generators. The high-quality gear motors manufactured by the company have proved to be an ideal choice for the oil and gas industry due to their reliability and durability.Power Generation IndustryThe power generation industry requires gear motors for various applications such as turbines, generators, and transformers. The gear motors manufactured by the company are designed to operate in harsh environments and are known for their reliability and durability.ConclusionIn conclusion, the gear motors manufactured by the company are widely used in various industries across the world. The company's commitment to quality and innovation has helped it to stay ahead of its competitors, making it a preferred supplier of gear motors to the industry. The gear motors manufactured by the company are designed to provide high efficiency, reliability, stability, and accuracy, making them an ideal choice for multiple industrial applications. With the increasing demands of industrial production, it has become more important than ever to use high-quality gear motors that can meet the requirements of modern-day industrial production, and the company is at the forefront of this revolution.

High-Powered 12v DC Motor: What You Need to Know

Motor Dc 12v (Brand Name Removed): Revolutionizing the Electric Motor IndustryInnovation is the key to success in any industry, and the electric motor industry is no exception. With the increasing demand for efficient and reliable electric motors, companies are constantly striving to develop cutting-edge technologies that meet the needs of the market. One such company that has been at the forefront of this push for innovation is [Company Name].Established in [year], [Company Name] has quickly made a name for itself as a leading manufacturer of high-quality electric motors. With a strong focus on research and development, the company has continuously pushed the boundaries of what is possible in the electric motor industry. Their commitment to innovation has led to the development of the Motor Dc 12v, a groundbreaking product that has revolutionized the industry.The Motor Dc 12v is a small but powerful electric motor that is designed to provide efficient and reliable performance in a wide range of applications. Whether it's used in automotive, industrial, or consumer electronics, this motor is able to deliver the power and precision needed to get the job done. What sets the Motor Dc 12v apart from other electric motors on the market is its advanced design and cutting-edge technology. With a focus on energy efficiency and durability, this motor is able to outperform its competitors in terms of performance and reliability.One of the key features of the Motor Dc 12v is its advanced brushless design, which allows for smoother operation and improved efficiency. This design also reduces the need for maintenance, making it an ideal choice for applications where reliability is essential. In addition, the motor is equipped with state-of-the-art control systems that allow for precise speed and torque control, allowing users to tailor its performance to their specific needs.Another significant advantage of the Motor Dc 12v is its compact size and lightweight construction. This makes it easy to integrate into a wide range of products and applications without adding unnecessary bulk or weight. As a result, the motor is able to offer superior performance without compromising on space or flexibility.Along with its exceptional performance and advanced design, the Motor Dc 12v is also backed by [Company Name]'s commitment to quality and customer satisfaction. The company prides itself on delivering products that exceed expectations, and the Motor Dc 12v is no exception. Each motor is subjected to rigorous testing and quality control measures to ensure that it meets the highest standards of performance and reliability. This dedication to quality has earned [Company Name] a reputation for excellence in the electric motor industry.Looking to the future, [Company Name] is committed to continuing its legacy of innovation and excellence in the electric motor industry. With a focus on sustainable and environmentally friendly technologies, the company is working to develop even more advanced products that will meet the needs of a rapidly changing market. The Motor Dc 12v is just the beginning of what promises to be a long line of innovative and groundbreaking products from [Company Name].In conclusion, the Motor Dc 12v is a testament to [Company Name]'s dedication to innovation and excellence in the electric motor industry. With its advanced design, superior performance, and commitment to quality, this motor is setting a new standard for electric motors. As the industry continues to evolve, [Company Name] will undoubtedly remain a driving force in shaping its future.

Screw Thread Linear Actuator for Precise Motion Control

Stepper Motor Screw - Revolutionizing the Precision in Industrial ManufacturingPrecision is paramount in industrial manufacturing processes. It not only ensures the quality of the products but also contributes to the overall efficiency and productivity of the manufacturing process. The stepper motor screw, a cutting-edge technology used in the industrial sector, has revolutionized precision in manufacturing processes.The stepper motor screw is a self-contained electromechanical system that enables accurate control of linear motion. The screw is driven by a stepper motor, which is a brushless electric motor that divides a full rotation into smaller steps. The combination of a stepper motor and a screw allows for precise and repeatable movement of machinery.The stepper motor screw has various industrial applications that range from industrial automation, robotics, 3D printing, CNC machining, and others. The self-contained system has gained broad acceptance due to its high level of accuracy, reliability, and repeatability. It has significantly impacted the manufacturing industry, enabling industries to produce high-quality products in an efficient, precise, and cost-effective manner.One company that has made significant milestones in the manufacturing industry is {remove brand name}. The company has a reputation for producing high-quality motion control systems, including stepper motor screws. They have a state-of-the-art manufacturing facility that produces a wide range of stepper motor screws tailored to different industrial applications.Their stepper motor screws are designed to offer exceptional precision, torque, and speed control. They have integrated the latest technology, including advanced control algorithms, to enhance the performance of their stepper motor screws. The company's products undergo rigorous testing to guarantee durability, reliability, and longevity.{Remove brand name} stepper motor screws are used in various industries, including the automotive, aerospace, energy, and medical industries. The screw enables the industries to produce parts and components with the highest precision and accuracy. The use of stepper motor screws enhances the manufacturing process's efficiency, which translates to cost savings, reduced waste, and timely delivery of products.One significant advantage of {Remove brand name} stepper motor screws is their ability to work in any environment. They have a high resistance to extreme temperatures, humidity, and dust, which makes them suitable for use in different manufacturing environments. Additionally, their products are designed to be low maintenance, which reduces downtime and increases productivity.The company's commitment to quality has translated to their products' recognition in the market. They have received various certifications for their products, including CE, UL, and RoHS. These certifications are a testament to their commitment to producing high-quality products that meet the highest global standards.In conclusion, the stepper motor screw, in combination with advanced control algorithms, has significantly impacted the manufacturing industry. It has enabled industries to produce high-quality products in a precise, efficient, and cost-effective manner. {Remove brand name} has been at the forefront of producing high-quality stepper motor screws that have revolutionized the industrial manufacturing process. Their commitment to quality, reliability, and durability has earned them a reputation as a leading manufacturer of motion control systems.

Revolutionary Flat Stepper Motor: Discover the Latest Advancement in Motor Technology

Title: Revolutionary Flat Stepper Motor Revolutionizes the Robotics IndustryIntroduction:In today's rapidly advancing technological landscape, innovation plays a crucial role in driving industries forward. To that end, a cutting-edge company has developed a groundbreaking device that promises to revolutionize the robotics industry. The flat stepper motor, created by an industry leader known for their commitment to technological advancements, has the potential to reshape the way robots interact with the world around them. By adhering to a minimalist design and leveraging advanced engineering techniques, this motor opens up a world of possibilities for robotics applications. Let's delve deeper into the features and implications of this game-changing device.Overview of Flat Stepper Motor:The now infamous flat stepper motor is a game-changing technology designed to provide robots with compact, lightweight, and precise movement capabilities. By removing bulky components and adopting a slim and compact design, this motor offers advantages in weight, size, and energy efficiency compared to traditional motors. Equipped with advanced control technology, the motor offers unparalleled accuracy and smoothness in its movements.One of the most significant advantages of the flat stepper motor is its low-profile design, which enables it to be seamlessly incorporated into a wide range of robotics applications, including surgical robots, industrial automation, and consumer electronics. Its compact size not only enhances flexibility in design but also reduces the overall weight of robot components, enabling greater maneuverability and cost-effective production.Noteworthy Features:The flat stepper motor boasts several impressive features that set it apart from other motors in the market:1. High Torque-to-Size Ratio: Incorporating advanced magnetic technology, this motor provides an exceptional torque-to-size ratio. Despite its compact dimensions, it offers robust and reliable performance, bringing increased power within smaller spaces.2. Precise Positioning: With its exceptional control technology, the motor ensures precise positioning and smooth movement even in complex robotic applications. This attribute is vital in industries like medicine, where accuracy and stability are of utmost importance.3. Energy Efficiency: The flat stepper motor consumes less power, making it an ideal choice for battery-powered applications. Its efficient operation not only prolongs the battery life but also reduces energy consumption, contributing to a more sustainable and eco-friendly solution.Application in the Robotics Industry:The introduction of this state-of-the-art flat stepper motor has the potential to transform the robotics industry in multiple ways:1. Medical Robotics: Surgical procedures require extremely precise and delicate movements. The flat stepper motor's unwavering accuracy and low profile are perfectly suited for assisting surgeons in performing intricate procedures. It enhances the safety and success rates of minimally invasive surgeries while reducing patient trauma.2. Industrial Automation: In factory floors, speed, precision, and reliability are essential for seamless production processes. With its compact size and high torque, the motor can be integrated into various automation applications, including conveyor systems, robotic arms, and assembly lines, to improve efficiency and productivity.3. Consumer Electronics: From wearable devices to smart home appliances, the flat stepper motor's compact design and energy efficiency make it a perfect fit for the consumer electronics market. Its robust control and smooth movement capabilities enhance functionality, ensuring a seamless user experience.Conclusion:The introduction of the flat stepper motor heralds a new era in robotics, providing compactness, precision, and efficiency hitherto unimagined. By revolutionizing industries such as medicine, manufacturing, and consumer electronics, this technology promises to reshape the world we live in.With a relentless commitment to innovation and a track record of cutting-edge developments, the company behind this revolutionary motor continues to pave the way for futuristic advancements in the field of robotics. As technology continues to push boundaries, the flat stepper motor stands as a testament to the limitless potential and possibilities that lie ahead.

Exploring the Advantages of Hybrid Stepper Motors in the Manufacturing Industry

[Company Name] Revolutionizes Hybrid Stepper Motor Industry with Cutting-Edge Technology[City, Date] – [Company Name], a leading manufacturer of high-performance hybrid stepper motors, stunned the industry with the launch of their latest innovation, setting a new benchmark for efficiency, precision, and reliability. With an unwavering commitment to technological advancement, [Company Name] continues to push the boundaries, delivering state-of-the-art solutions that redefine industry standards.As a trailblazer in the hybrid stepper motor market, [Company Name] has gained worldwide recognition for their commitment to excellence. With a diverse range of products catering to various industries, their motors have become synonymous with quality, reliability, and innovation.The newly launched hybrid stepper motor, the [Product Name], is set to revolutionize industrial automation. Boasting a multitude of cutting-edge features and advancements, this motor promises unparalleled performance and efficiency.One of the key features of the [Product Name] is its advanced microstep control technology. With this breakthrough technology, the motor can better control movement and achieve smoother motion, eliminating the drawbacks of traditional stepper motors. This enables operators to achieve higher precision and positional accuracy, making it ideal for applications in robotics, medical equipment, and CNC machines.Additionally, the [Product Name] incorporates a compact design without compromising on capability. By utilizing advanced materials and miniaturization techniques, [Company Name] has managed to develop a motor that is not only smaller in size but also more powerful and efficient. This compact design allows for easier integration into various machinery and equipment, making it incredibly versatile.[Company Name] prides itself on its commitment to sustainability, and the [Product Name] exemplifies this ethos. The motor's innovative design and high-efficiency operation reduce energy consumption, ultimately minimizing carbon emissions. This not only benefits the environment but also lowers operational costs for manufacturers. By investing in the [Product Name], businesses can not only enhance their productivity but also contribute to a greener future.Furthermore, [Company Name] understands the importance of reliability and longevity in industrial settings. That is why the [Product Name] incorporates cutting-edge materials and meticulous manufacturing processes to ensure its durability. Coupled with advanced cooling systems and enhanced protection features, this motor can withstand even the harshest operating conditions, guaranteeing uninterrupted performance and reducing costly machine downtime.Quality control has always been a priority for [Company Name]. The [Product Name] undergoes rigorous testing and inspection at every stage of the manufacturing process to ensure that each unit meets the highest industry standards. This dedication to quality has garnered the trust and confidence of customers across the globe.As a leading manufacturer in the hybrid stepper motor industry, [Company Name] has a global sales and distribution network. Their extensive network ensures that clients from different parts of the world can easily access their products and benefit from their cutting-edge technology. With a dedicated customer support team, [Company Name] provides exceptional after-sales service, catering to the diverse needs and requirements of their clients.To sum up, [Company Name]'s latest breakthrough, the [Product Name], is set to reshape the hybrid stepper motor industry. With its advanced microstep control technology, compact design, and commitment to sustainability, this motor is primed to become an essential component of industrial automation systems. [Company Name] continues to lead the charge in innovation, delivering top-notch products and unmatched service, solidifying their position as a frontrunner in the market.About [Company Name]:[Company Name] is a renowned manufacturer of high-performance hybrid stepper motors. With a strong focus on innovation and sustainability, they provide industry-leading solutions to customers worldwide. As pioneers in the field, [Company Name] consistently delivers cutting-edge products that exceed industry standards, earning them a reputation as a trusted partner in industrial automation. For more information, visit [Company Website].

Guide to Understanding DC Gear and Brushless Motors from China

China DC Gear Motor and Brushless DC MotorChina is quickly becoming a global leader in producing high-quality DC gear motors and brushless DC motors. These motors have a wide range of applications in various industries, including automotive, robotics, aerospace, and healthcare.DC gear motors are widely used in industries where there is a need for controlled speed and torque. They are known for their excellent efficiency, compact size, and reliability. These motors are primarily used in applications such as robotics, industrial machinery, and automotive systems.Brushless DC motors, on the other hand, are gaining immense popularity due to their high efficiency and durability. They are widely used in electric vehicles, drones, medical equipment, and industrial automation. Unlike traditional brushed motors, brushless DC motors have a longer lifespan and require less maintenance.China boasts a robust manufacturing infrastructure for DC gear motors and brushless DC motors. The country's advanced technology and skilled workforce allow manufacturers to produce motors that meet high-quality standards at competitive prices. With numerous factories spread across the country, China has become a one-stop destination for businesses looking for reliable and cost-effective motor solutions.One prominent company contributing to the success of China's DC gear motor and brushless DC motor industry is [Company Name]. With over [number] years of experience in motor manufacturing, the company has established itself as a leader in producing technologically advanced motors.[Company Name] specializes in the research, development, and production of a wide range of DC gear motors and brushless DC motors. Their motors are known for their exceptional performance, reliability, and energy efficiency. The company takes pride in its state-of-the-art production facilities and strict quality control measures that ensure consistent product quality.The company's DC gear motors are designed to provide precise control of speed and torque, making them suitable for various industrial applications. These motors are equipped with advanced gear systems that deliver smooth operation and reduce noise levels. Additionally, [Company Name]'s DC gear motors are highly customizable, allowing customers to tailor the motor's specifications to meet their specific needs.In the field of brushless DC motors, [Company Name] stands out for its innovative designs and advanced technology. The company's brushless DC motors offer high power density and excellent thermal performance, making them ideal for demanding applications. These motors are equipped with intelligent control systems that ensure accurate speed and position control.Moreover, [Company Name] emphasizes environmental sustainability in its motor production process. The company actively adopts eco-friendly manufacturing practices, such as using high-efficiency components and reducing energy consumption. This commitment to sustainable manufacturing aligns with China's push for a greener economy and has gained [Company Name] recognition as an environmentally responsible motor manufacturer.As the demand for DC gear motors and brushless DC motors continues to grow, [Company Name] is dedicated to pushing the boundaries of motor technology. The company invests significantly in research and development to stay ahead of the competition and cater to evolving market needs.In conclusion, China's DC gear motor and brushless DC motor industry have flourished due to the country's manufacturing capabilities and technological advancements. [Company Name] exemplifies the industry's success with its commitment to producing high-quality, customizable, and eco-friendly motors. With China's continued focus on innovation and sustainability, the future of the country's motor industry looks promising.

High-Quality Micro Motor for Various Applications - Everything You Need to Know

ODM Micro Motor, a leading manufacturer of micro motors, is revolutionizing the industry with its cutting-edge technology and innovative solutions. The company is dedicated to providing high-quality, reliable micro motors for a wide range of applications, including automotive, consumer electronics, medical devices, and industrial equipment.With a strong focus on research and development, ODM Micro Motor has a team of highly skilled engineers and technicians who are constantly pushing the boundaries of what is possible in the field of micro motor technology. The company's state-of-the-art facilities are equipped with the latest equipment and technology, allowing them to design and produce micro motors that are smaller, more efficient, and more powerful than ever before.What sets ODM Micro Motor apart from its competitors is its commitment to quality and customer satisfaction. The company's rigorous quality control processes ensure that every micro motor that leaves their facility meets the highest standards of reliability and performance. In addition, ODM Micro Motor works closely with its customers to understand their specific needs and requirements, allowing them to develop customized solutions that are tailored to each individual application.One of the key strengths of ODM Micro Motor is its ability to produce micro motors in high volume while maintaining consistently high quality. The company's advanced manufacturing processes and strict quality control measures enable them to produce large quantities of micro motors without sacrificing quality or performance. This has made ODM Micro Motor a preferred supplier for many leading companies in industries such as automotive, consumer electronics, and medical devices.In addition to its focus on quality and innovation, ODM Micro Motor is also committed to sustainability and environmental responsibility. The company prioritizes the use of eco-friendly materials and processes in its manufacturing operations, and is constantly seeking ways to reduce its environmental impact. This dedication to sustainability has not gone unnoticed, and ODM Micro Motor has received recognition and awards for its efforts in this area.ODM Micro Motor's dedication to excellence and innovation has positioned the company as a leader in the micro motor industry. With its state-of-the-art technology, commitment to quality, and focus on customer satisfaction, ODM Micro Motor is poised to continue driving the industry forward and shaping the future of micro motor technology.In conclusion, ODM Micro Motor is a company that is dedicated to pushing the boundaries of what is possible in the field of micro motor technology. With its advanced technology, commitment to quality, and focus on customer satisfaction, ODM Micro Motor is well positioned to continue driving the industry forward and shaping the future of micro motor technology.