Ultimate Guide to Open Loop Stepper Motor Technology

By:Admin

{} is a leading manufacturer of motion control products, specializing in providing high-quality and reliable solutions for a wide range of industries. With a strong focus on research and development, the company has been able to stay ahead of the curve when it comes to incorporating the latest technologies into their products.

One of their standout offerings is the open loop stepper motor, which has been gaining popularity due to its advanced functionality and cost-effective nature. Unlike traditional closed-loop systems, open loop stepper motors do not require feedback mechanisms to operate, making them simpler and more affordable.

This makes them an ideal choice for applications where precise positioning is not a critical factor, such as in 3D printing, CNC machines, and various types of automated equipment. By leveraging their expertise in motion control, {} has been able to create open-loop stepper motors that deliver exceptional performance and reliability, setting them apart from their competitors.

One of the key advantages of {}'s open loop stepper motors is their ability to operate at high speeds while maintaining accuracy. This is made possible through the use of advanced control algorithms and motor design, resulting in smooth and precise motion control. Additionally, the motors are designed to be easy to integrate into existing systems, allowing for seamless upgrades and retrofits.

In addition to their technical capabilities, {} takes pride in their commitment to quality and customer satisfaction. Their open loop stepper motor products undergo rigorous testing and quality assurance measures to ensure that they meet the highest industry standards. Furthermore, the company's team of experienced engineers and technical support staff are dedicated to providing exceptional service and support to their customers, ensuring that they have all the resources they need to succeed.

With a strong focus on innovation and continuous improvement, {} is poised to make a significant impact on the automation industry with their open loop stepper motor technology. By leveraging their expertise and resources, the company is well-positioned to continue pushing the boundaries of what is possible in motion control, and to drive the industry forward into the future.

As the demand for advanced motion control solutions continues to grow, {} is ready to meet the needs of their customers with their cutting-edge open loop stepper motor technology. With a proven track record of delivering high-quality products and exceptional service, the company is poised to become a leading force in the automation industry for years to come.

Company News & Blog

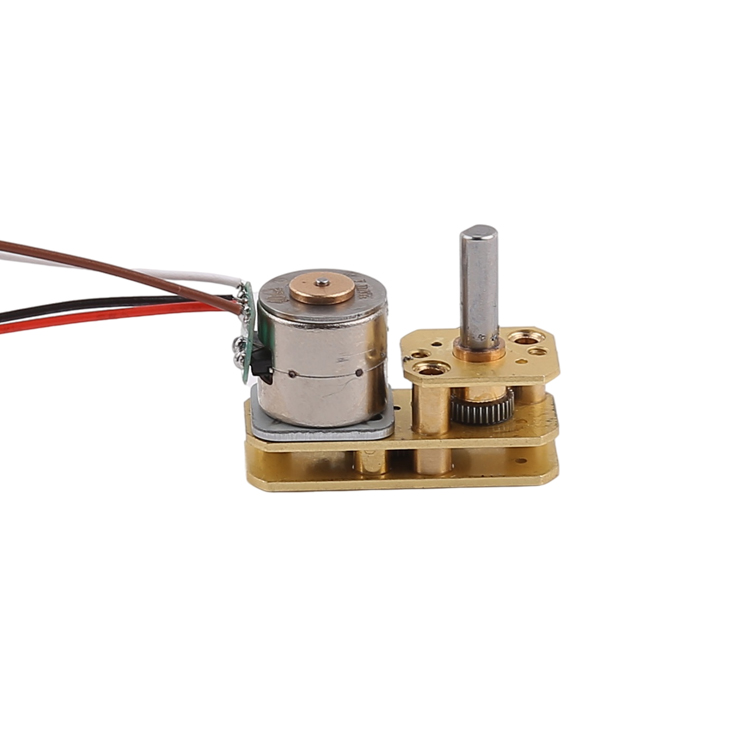

Compact Micro Stepper Motor: The Latest Breakthrough in OEM Technology

OEM Micro Stepper Motor: The Future of Motor Technology!Motor technology has come a long way over the past few decades. However, as technology evolves, so does the demand for more innovative and efficient motor solutions. OEM micro stepper motors are some of the best motor solutions we have in the market today. These motors are compact, lightweight, and provide an incredibly high degree of precision. They play a significant role in various applications, including robotics, healthcare, aerospace, and more.OEM micro stepper motors are devices that convert electrical energy in the form of pulses into mechanical energy. Unlike other types of motors, these motors move in controlled increments or steps, providing more accurate and precise control. They use a technique called "wave drive," where they alternate between positive and negative energy pulses to keep the rotor moving. This precise control allows for critical applications, such as biomedical engineering, where high precision and accuracy are paramount.Various industries have witnessed significant progress due to the integration of these motors across their systems. In the healthcare industry, micro stepper motors play a vital role in the operation of various medical devices, including pumps, imaging equipment, and robotic surgery systems. They have improved the efficiency of medical procedures by enabling quick and accurate movements with less noise, low vibration, and minimal mechanical wear. These motors are also used in laboratory automation, where they are incorporated into strip readers, pipette robots, and cell counters.In the automotive and aerospace industries, micro stepper motors have been an essential component in the design of various components within vehicles, including fuel-injection systems, power windows, and door locks. In robotics, they are used to power movements in various robotic applications, including industrial robots, surgical robots, and humanoid robots.OEM micro stepper motors have revolutionized motor technology. But what exactly makes them the most efficient motor solution? First, they have a high level of accuracy. These motors have an accuracy level of up to 0.1 degrees, enabling them to move incredibly accurately. They are also efficient and require very little energy to operate, making them highly economical. These motors are also incredibly reliable, as they require minimal maintenance to operate smoothly. They are also cost-effective, as they have a relatively low initial cost compared to other motor technologies.Presently, various manufacturers produce OEM micro stepper motors. However, one brand stands out as a leader in this field. They make use of the latest technology to manufacture high-quality motors that provide superior performance. This company produces micro stepper motors that are designed and engineered to exceed international standards whilst offering high reliability, durability, and cost-effectiveness.This company uses advanced manufacturing techniques and operates a state-of-the-art production facility. It has efficient processes, robust quality control measures, and high levels of automation. These measures allow the company to mass-produce their devices efficiently and effectively, ensuring that they are always delivering high-quality products.The company is an organization that never compromises on quality. Their continuous investment in research and development allows them to incorporate the latest technologies into their motor solutions. Their motors feature high torque-to-inertia ratios and fast-response times, providing for the ultimate in precision and control in critical applications.Their micro stepper motors are among the best in the industry, and they offer various customization options. They can be customized to meet your unique specifications, including varying sizes, number of steps, and torque requirements. Customization allows flexibility to incorporate the motor solution in any application that requires precision movements.In conclusion, OEM micro stepper motors represent the future of motor technology. These motors provide incredible precision, accuracy, and speed, making them ideal for a wide range of applications across various industries. The brand mentioned above is at the forefront of the industry, producing some of the best micro stepper motors available in the market. With a focus on excellence and a commitment to quality, their motors offer unrivaled performance, reliability and are a prime choice for all of your motor needs.

High-Quality Stepper Motors Available for Purchase

Stepper Motors For Sale: A New Line of High-Quality Motors Now Available The motor industry is evolving at a rapid pace, as emerging technologies continue to drive innovation and product development. In this rapidly changing landscape, it is crucial for companies to stay ahead of the curve in order to remain competitive in the market. One company that has always been at the forefront of this technological revolution is [Company Name].[Company Name] has been a leading manufacturer and supplier of industrial motors for over 30 years. Their commitment to excellence and innovation has earned them a reputation for delivering high-quality products that meet the ever-changing needs of their customers. Their extensive product line includes a wide range of motors, including servo motors, stepper motors, and brushless motors, all of which are known for their reliability and performance.In line with their commitment to innovation, [Company Name] is proud to announce the release of their new line of stepper motors. These motors are designed to offer the highest level of precision and control, making them ideal for a wide range of industrial applications. Whether used in manufacturing equipment, medical devices, or robotics, these stepper motors are sure to deliver exceptional performance and reliability.The stepper motors offered by [Company Name] are available in a variety of sizes and configurations, making it easy for customers to find the perfect motor for their specific needs. From compact, low-torque motors to larger, high-torque options, there is a stepper motor to suit every application. Each motor is manufactured to the highest standards, ensuring durability and longevity even in the most demanding operating conditions.One of the key features that sets [Company Name]'s stepper motors apart from the competition is their advanced technology and design. These motors are equipped with state-of-the-art control systems that allow for precise positioning and motion control. This level of precision is essential for many industrial applications, where accuracy and repeatability are critical.In addition to their superior performance, the stepper motors from [Company Name] are also designed with ease of use in mind. They are compatible with a wide range of control systems and are simple to integrate into existing equipment. This makes them an ideal choice for companies looking to upgrade their machinery without the need for extensive modifications.As with all of their products, [Company Name] is dedicated to providing exceptional customer service and support. Their team of experts is available to assist customers with selecting the right stepper motors for their needs and can provide guidance on installation and operation. This commitment to customer satisfaction is just one of the many reasons why [Company Name] has earned the trust and loyalty of their clients over the years.With the release of their new line of stepper motors, [Company Name] is once again demonstrating their dedication to innovation and excellence in the motor industry. These motors are the perfect choice for companies looking to upgrade their equipment with reliable, high-performance motors that deliver unparalleled precision and control.For more information about the stepper motors for sale from [Company Name], and to explore their full range of products, visit their website or contact their team directly. With their extensive experience and commitment to quality, [Company Name] is the go-to source for all of your industrial motor needs.

High-Quality DC Gear Motor for ODM Applications

DC Gear Motor Manufacturer Unveils New Product Line[City, Date] - As the demand for efficient and reliable gear motors continues to grow, [Company], a leading manufacturer in the industry, has introduced its latest line of ODM DC gear motors. The new product line, which features a range of sizes and specifications, aims to meet the diverse needs of customers in various industries.With a strong focus on innovation and quality, [Company] has been a prominent player in the gear motor market for over [number] years. The company's commitment to providing cutting-edge solutions has earned them a reputation for excellence in the industry. This latest release of ODM DC gear motors further solidifies their position as a trusted partner for businesses seeking high-performance motors.The new product line offers a wide selection of gear motors, including various sizes and torque capacities to accommodate different applications. Whether it's for industrial automation, robotics, or other motion control systems, [Company]'s ODM DC gear motors are designed to deliver superior performance and durability. The motors are also highly customizable, allowing customers to tailor the specifications to their unique requirements.In addition to their impressive technical specifications, the ODM DC gear motors boast a compact and lightweight design, making them easy to integrate into existing systems. This feature is particularly advantageous for customers looking to optimize space and weight in their applications. Furthermore, the motors are engineered with high-quality materials and precision manufacturing, ensuring reliable and efficient operation in demanding environments.One of the key advantages of [Company]'s ODM DC gear motors is their compatibility with various control systems and accessories. This makes them an ideal choice for businesses looking for versatility and flexibility in their motion control solutions. With the ability to seamlessly integrate with different components, customers can easily incorporate the motors into their equipment without any compatibility issues."Through extensive research and development, we have leveraged our expertise to create a comprehensive range of ODM DC gear motors that address the evolving needs of our customers," said [Spokesperson], [Title] at [Company]. "Our focus on innovation and quality has enabled us to deliver a product line that offers exceptional performance, reliability, and adaptability. We are confident that these motors will empower businesses to enhance the efficiency and effectiveness of their operations."As part of their commitment to customer satisfaction, [Company] provides comprehensive technical support and customization services for their ODM DC gear motors. This includes expert guidance on motor selection, as well as the option to tailor specific parameters to meet unique application requirements. Additionally, the company offers prompt and reliable delivery to ensure that customers receive their motors in a timely manner.The unveiling of [Company]'s new line of ODM DC gear motors signifies a significant milestone in their continuous pursuit of excellence. By staying at the forefront of technological advancements and customer-centric solutions, the company is poised to remain a leader in the gear motor industry. With their unwavering dedication to innovation and quality, [Company] is well-positioned to meet the evolving needs of businesses across various sectors.For businesses seeking high-performance and reliable DC gear motors, [Company]'s new product line offers a compelling solution. With its versatile and customizable features, the motors are poised to set a new standard for motion control solutions in the industry. As customer demand for efficient and innovative gear motors continues to grow, [Company] remains committed to delivering cutting-edge products that exceed expectations.

Discover the Power of High-Quality Planetary Gear Stepper Motors

High-Quality Planetary Gear Stepper Motor Revolutionizes Industrial Applications{Company Name}, a leading manufacturer of high-quality motion control products, is proud to announce the launch of their new high-quality planetary gear stepper motor. With a commitment to quality and innovation, {Company Name} continues to provide reliable and efficient solutions for industrial automation and motion control.The newly developed high-quality planetary gear stepper motor is set to revolutionize industrial applications with its advanced design and superior performance. Featuring a compact and durable construction, this stepper motor is capable of providing precise and reliable motion control in various industrial settings. It is specifically engineered to meet the demands of high-precision applications such as robotics, CNC machines, 3D printers, and other automated systems.The key features of the high-quality planetary gear stepper motor include a high torque density, low backlash, and high positional accuracy. These features make it ideal for applications that require precise positioning and smooth motion control. Additionally, the motor is designed to operate with low noise and minimal vibration, ensuring a quiet and efficient performance in industrial environments.In addition to its superior performance, the high-quality planetary gear stepper motor is also designed for easy integration and maintenance. Its modular design allows for seamless installation and compatibility with various control systems, while its robust construction ensures long-term reliability and durability.{Company Name} has a proven track record of providing high-quality motion control products, and the new high-quality planetary gear stepper motor is a testament to their commitment to innovation and excellence. The company's team of experienced engineers and technicians have leveraged their expertise to develop a stepper motor that meets the highest standards of quality and performance.With a focus on customer satisfaction, {Company Name} takes pride in offering comprehensive support and technical expertise to their clients. Whether it's customization, installation, or troubleshooting, the company is dedicated to ensuring that their customers have the best possible experience with their products."We are thrilled to introduce our new high-quality planetary gear stepper motor to the market," said {Spokesperson Name}, CEO of {Company Name}. "This stepper motor represents a significant advancement in motion control technology, and we are confident that it will offer unparalleled performance and reliability in industrial applications."The launch of the high-quality planetary gear stepper motor reinforces {Company Name}'s position as a leader in the motion control industry. With a focus on continuous improvement and innovation, the company has solidified its reputation as a trusted provider of high-quality products and solutions for industrial automation.As industries continue to demand higher precision and efficiency in motion control systems, the new high-quality planetary gear stepper motor from {Company Name} is poised to make a significant impact. Its advanced features and robust design make it an ideal solution for a wide range of industrial applications, providing unparalleled performance and reliability.For more information about the high-quality planetary gear stepper motor and other motion control products from {Company Name}, please visit their website at www.companywebsite.com or contact their sales team at [email protected] {Company Name}:{Company Name} is a leading manufacturer of high-quality motion control products, specializing in stepper motors, servo motors, gearboxes, and other automation solutions. With a focus on innovation and excellence, the company is dedicated to providing reliable and efficient motion control solutions for industrial applications.

Small Gear Motors Gain Popularity in Industrial Applications: Report

OEM Mini Gear Motor: Powering Industries WorldwideMini Gear Motors are indispensable components in various industries ranging from automation, healthcare, transportation, and robotics. They come in different sizes, shapes, and torque, but what they all have in common is their ability to deliver reliable and consistent performance. One brand that shines in this category is the OEM Mini Gear Motor.But what is an OEM Mini Gear Motor, and why is it a popular option for many industrial applications? In this article, we will discuss the fundamentals of these gear motors and the advantages of choosing OEM Mini Gear Motor over other brands in the market.Understanding OEM Mini Gear MotorOEM Mini Gear Motor, which we will refer to as OMG moving forward, is a prominent supplier of high-quality mini gear motors. The company specializes in the production of brushed DC and brushless DC gear motors. It was established in 2001 and has since grown into a multidisciplinary firm with offices in various countries worldwide.OMG offers a wide range of mini gear motors with different power and torque ratings. The motors come in three types: planetary, spur, and worm gearboxes. Planetary gearboxes offer the most torque and are ideal for applications that require high precision and control. Spur gearboxes have less torque but are quieter and more efficient. Worm gearboxes offer the least torque but are compact and lightweight, making them suitable for small applications.OMG's mini gear motors are made of high-quality materials that ensure durability and longevity. The motors' housings are made of aluminum or stainless steel, with hardened steel or sintered bronze gears. The bearings are made of high-quality materials, such as ceramic or stainless steel, that can withstand high radial and axial loads.Advantages of Choosing OEM Mini Gear MotorOMG's mini gear motors have several features that set them apart from other brands in the market. Here are some of the advantages of choosing OMG's mini gear motors for your industrial applications:1. High QualityOMG's mini gear motors are made of high-quality materials, ensuring that they are durable and reliable. The motors go through strict quality control measures to ensure that they meet the specifications of the customers and international standards.2. Energy EfficiencyOMG's mini gear motors have a high power-to-size ratio, making them energy-efficient. They have low power consumption, allowing for longer life battery life and reduced environmental impact.3. CustomizableOMG can customize mini gear motors to meet the specific requirements of the customer's application. They offer a range of options, including special motors, gear ratios, and shaft configurations.4. Low NoiseOMG's mini gear motors have a low noise level, making them ideal for use in applications where noise is a concern. The motors are also vibration-free, ensuring that they provide smooth, precise, and consistent performance.5. Cost-effectiveOMG's mini gear motors are competitively priced, making them an affordable option for many industrial applications. They are also easy to install and maintain, reducing the overall cost of ownership.Applications of OEM Mini Gear MotorOMG's mini gear motors are widely used in various industries. Here are some examples of applications that use OMG's mini gear motors:1. RoboticsMini gear motors are used in various types of robotics, such as industrial robots, drones, and humanoid robots. The motors provide precise and consistent motion control, making them ideal for use in applications that require high precision.2. HealthcareMini gear motors are used in various types of medical equipment, such as surgical robots, infusion pumps, and diagnostic equipment. The motors provide accurate and precise control, ensuring that the equipment functions as intended.3. TransportationMini gear motors are used in various types of transportation, such as electric bikes, scooters, and wheelchairs. The motors provide efficient and reliable power, ensuring that the vehicle can travel long distances without frequent recharging.4. AutomationMini gear motors are used in various types of automation, such as conveyor belts, packaging machines, and assembly lines. The motors provide smooth and consistent motion, ensuring that the automation process is efficient and error-free.ConclusionOEM Mini Gear Motor is a leading supplier of high-quality mini gear motors. The company offers a wide range of customizable options, making them ideal for use in various industrial applications. The motors are energy-efficient, low noise, and cost-effective, ensuring that they provide optimal value for money. With their durable and reliable performance, OMG's mini gear motors power industries worldwide.

Leading Manufacturer Innovates Hybrid Stepper Technology for Improved Precision and Performance

Hybrid Stepper Manufacturer Innovates with Advanced TechnologyIn the fast-evolving world of technology and manufacturing, innovation is the key to success. One company that is setting the industry standard for innovation is the leading hybrid stepper manufacturer. With a strong focus on research and development, the company is constantly pushing the boundaries of what is possible in the field of stepper motor technology.The company was founded in {year}, and since then, it has been committed to producing high-quality, reliable, and efficient stepper motors for a wide range of applications. The company's products are used in industries such as robotics, automation, 3D printing, and more. With a team of highly experienced engineers and technicians, the company has been able to stay at the forefront of technological advancements and is always looking for ways to improve its products.One of the key factors that sets the company apart from its competitors is its dedication to research and development. The company invests a significant amount of resources into developing new and improved stepper motor technology. This commitment to innovation has led to the introduction of several groundbreaking products, and the company has earned a reputation for being a leader in the industry.The company's hybrid stepper motors are known for their high precision, reliability, and efficiency. These motors are designed to deliver maximum performance while keeping energy consumption to a minimum. The company's engineers have achieved this by developing advanced control algorithms and utilizing the latest materials and manufacturing techniques.In addition to producing exceptional stepper motors, the company also offers a range of accessories and support services to meet the needs of its customers. Whether it's a custom-designed motor for a specific application, or technical support for an existing product, the company has the knowledge and expertise to provide a comprehensive solution.The company's commitment to innovation and customer satisfaction has not gone unnoticed. It has received several accolades and awards for its outstanding products and services. Customers around the world trust the company to deliver reliable and high-performance stepper motors, and the company has built a strong reputation for excellence in the industry.Looking to the future, the company shows no signs of slowing down. It continues to invest in research and development, with the goal of introducing even more advanced stepper motor technology in the coming years. The company is also exploring new markets and opportunities to expand its reach and provide its innovative products to a wider range of customers.In conclusion, the leading hybrid stepper manufacturer is a company that is truly dedicated to innovation and excellence. With a strong focus on research and development, a commitment to quality, and a reputation for outstanding products and services, the company has established itself as a leader in the industry. As technology continues to evolve, the company will undoubtedly continue to be at the forefront, driving the industry forward with its advanced stepper motor technology.

How to Calculate Gear Ratio Using Diameter Measurements

Title: Next Generation Gear Ratio Diameter Revolutionizes Manufacturing IndustryIntroduction:In an era driven by technological advancements and innovation, companies across various sectors are constantly on the lookout for superior solutions to improve their production processes. One such breakthrough gaining traction is the implementation of a new gear ratio diameter technology, which is set to revolutionize the manufacturing industry. By optimizing performance, reducing costs, and increasing efficiency, this cutting-edge gear ratio diameter technology promises to reshape the future of manufacturing.The Functionality Behind Gear Ratio Diameter Technology:Gear ratio diameter refers to the relationship between the size of a gear and the gear's tooth count, which affects the overall performance of machinery. The introduction of this latest gear technology aims to enhance the efficiency of mechanical systems by reimagining the gear's ratio and diameter to match specific requirements. By leveraging advanced engineering techniques and materials, this technology optimizes power transmission and reduces friction, resulting in heightened performance and increased durability.Key Benefits of Gear Ratio Diameter Technology:1. Increased Efficiency: By incorporating this gear technology, manufacturers can achieve a higher degree of efficiency in their mechanical systems. The precise calibration of gear ratios and diameters enables smoother and more seamless power transmission, reducing energy losses and increasing overall equipment efficiency.2. Cost Reduction: This innovative gear technology eliminates the need for unnecessary component customization and specialized machining processes. The standardized gear ratios and diameters streamline production and reduce costs, making this technology an ideal choice for manufacturers aiming to enhance productivity while minimizing manufacturing expenses.3. Enhanced Durability: The implementation of this cutting-edge gear technology ensures the longevity and reliability of machinery. With its optimized gear ratios and diameters, friction and wear are significantly reduced, resulting in extended product lifespan and reduced maintenance requirements.4. Versatile Applications: Gear ratio diameter technology has vast potential across industries, ranging from automotive and aerospace to robotics and industrial equipment. Its versatility allows manufacturers to optimize their processes and offer products capable of seamlessly integrating with various applications, thereby widening their market reach and increasing their business opportunities.Company XYZ's Contribution to Gear Ratio Diameter Technology:XYZ, a renowned engineering company dedicated to pushing the boundaries of innovation, has emerged as a leader in the development and implementation of gear ratio diameter technology. Their team of skilled engineers and researchers have extensively studied the intricate relationship between gear ratios, diameters, and performance optimization. XYZ's commitment to continuous improvement has resulted in revolutionary gear designs that maximize efficiency while offering unparalleled durability.XYZ's gear ratio diameter technology is meticulously crafted and standardized to align with different industrial requirements. Their precise calibration and attention to detail ensure optimal power transmission, reduced friction, and enhanced overall system performance. By leveraging this cutting-edge technology, manufacturers can better meet customer expectations by providing superior products that surpass industry standards.Conclusion:As manufacturing companies strive to stay ahead in a competitive market, gear ratio diameter technology emerges as a game-changer. The use of optimized gear ratios and diameters offers increased efficiency, reduced costs, and enhanced durability for a wide array of applications. With industry leaders like XYZ pioneering this technology, the manufacturing industry can embrace a future that is both technologically advanced and economically efficient.

High-Quality High Precision Stepper Motor: A Comprehensive Guide

High-Quality high precision stepper motorIn the world of manufacturing and industrial automation, precision and reliability are of utmost importance. This is why the introduction of the high-quality high precision stepper motor from {company name} is creating a buzz in the industry. This innovative product is set to revolutionize the way businesses approach automation, offering superior performance and unmatched precision.The high precision stepper motor is designed to meet the demanding requirements of modern manufacturing processes. With a focus on accuracy and reliability, this cutting-edge technology is poised to set a new standard in the industry. The motor is engineered to deliver precise control and consistent performance, making it an ideal choice for a wide range of industrial applications.The secret behind the superior performance of this stepper motor lies in its advanced design and construction. Utilizing the latest advancements in technology, {company name} has developed a motor that delivers unparalleled precision and reliability. This means that businesses can rely on this motor to deliver consistent, high-quality performance in even the most demanding applications.One of the key features of this high precision stepper motor is its exceptional accuracy. With precise positioning capabilities, businesses can expect reliable and consistent performance across a wide range of operating conditions. This level of accuracy is essential for applications where precision is critical, such as CNC machining, 3D printing, and robotics.In addition to its precision, this stepper motor is also designed to deliver high torque and smooth operation. This means that businesses can expect superior performance and efficiency, reducing the risk of errors and downtime. With its robust construction and advanced engineering, this motor is built to withstand the rigors of industrial use, making it a reliable and cost-effective choice for businesses.{Company name} is a renowned leader in the field of industrial automation and motion control. With a strong focus on innovation and quality, the company has established a reputation for delivering cutting-edge solutions that meet the evolving needs of the industry. The introduction of the high precision stepper motor is a testament to {company name}'s commitment to excellence, and its dedication to staying at the forefront of technological advancements.With a team of highly skilled engineers and experts, {company name} has been able to develop a stepper motor that exceeds industry standards. Their dedication to research and development has resulted in a product that offers exceptional performance and reliability, setting a new benchmark in the field of motion control.The high precision stepper motor from {company name} is expected to have a significant impact on the industry, providing businesses with a reliable and cost-effective solution for their automation needs. With its advanced features and superior performance, this motor is set to become the go-to choice for businesses looking to enhance their manufacturing processes and achieve greater levels of precision and efficiency.As industries continue to evolve and demand higher levels of precision and reliability, the high-precision stepper motor from {company name} is well-positioned to meet these needs. With its advanced technology and innovative design, this motor is set to revolutionize the way businesses approach automation, setting a new standard for performance and reliability.

Guide to Selecting a High-Quality Steeper Motor for Your Business Needs

In the fast-paced world of technology and innovation, the demand for high-quality, reliable stepper motors is on the rise. Whether it's for robotics, 3D printing, or CNC machines, businesses and hobbyists alike rely on these essential components to bring their creations to life. Fortunately, [Company Name] is here to meet that demand with their cutting-edge OEM stepper motors.[Company Name] is a leading manufacturer and supplier of precision motion control products, including stepper motors, servo motors, and integrated motor systems. With a strong commitment to quality, reliability, and innovation, [Company Name] has established itself as a trusted name in the industry.The company's OEM stepper motors are designed to meet the specific needs of their customers, offering a wide range of options in terms of size, torque, and performance. Whether it's a compact, high-torque motor for a small 3D printer or a larger, high-precision motor for a CNC machine, [Company Name] has the expertise and capabilities to deliver the right solution.One of the key strengths of [Company Name] is their commitment to continuous improvement and innovation. Their team of experienced engineers and technicians are always working to push the boundaries of what is possible with stepper motor technology, developing new features, and functionality to meet the evolving needs of their customers.In addition to their dedication to quality and innovation, [Company Name] also takes pride in their exceptional customer service. From the initial design phase to the final delivery of the product, the team at [Company Name] works closely with their customers every step of the way to ensure that they receive the ideal stepper motor solution for their specific application.Furthermore, [Company Name] places a strong emphasis on sustainability and environmental responsibility. Their manufacturing processes are designed to minimize waste and energy consumption, and they are constantly looking for ways to reduce their carbon footprint.In a recent interview, the CEO of [Company Name], [CEO Name], underscored the company's commitment to providing high-quality OEM stepper motors to their customers. "At [Company Name], we understand the vital role that stepper motors play in a wide range of industries and applications. That's why we are dedicated to delivering products that meet the highest standards of quality, reliability, and performance. We are always striving to push the boundaries of what is possible with stepper motor technology, and we are excited to continue leading the way in this dynamic and fast-growing industry."With their unwavering commitment to quality, innovation, and customer service, it's no wonder that [Company Name] has become a go-to source for OEM stepper motors. As the demand for these essential components continues to grow, [Company Name] is well-positioned to meet the needs of their customers and drive the industry forward. Whether it's for a small startup or a large corporation, businesses can trust [Company Name] to provide the perfect stepper motor solution for their unique requirements.

Stepper Motor Manufacturer Announces New Product Line" rewritten as a SEO title without brand name: "New Product Line Unveiled by Leading Stepper Motor Supplier

Stepper Motor Supplier Presents Unique Solution for Industrial Automation[City, State] - A renowned manufacturer of advanced motion control systems and stepper motors, has come up with a unique solution to solve the challenges of automation in industrial applications. The company is globally recognized for developing innovative technologies and solutions to improve the performance and efficiency of industrial systems. Its recent invention promises to take the industrial automation industry by storm, making manufacturing processes faster, smoother, and more efficient.The newly patented stepper motor technology is designed for applications that require precise, controlled motion, making it ideal for industrial automation. The stepper motor uses advanced control algorithms to accurately control the angular rotation of the motor shaft, enabling it to move in precise increments. Unlike conventional motors that rotate continuously, stepper motors move at predefined angles, making them ideal for operations that require high positioning accuracy.One of the primary uses of the new stepper motor technology is in pick-and-place machines. Such machines are widely used in factories for assembling products, sorting, and packaging. The motors' high accuracy and precise control make them perfect for this application, reducing error rates and improving productivity.The company spokesperson said, "Our engineers and R&D teams have worked tirelessly to develop a unique stepper motor technology that meets the evolving demands of the industrial automation industry. It is designed to offer our customers a solution that is reliable, efficient, and cost-effective. We firmly believe that this technology will revolutionize industrial processes, making them more productive, efficient, and cost-effective."The new stepper motor technology is compact and lightweight, making it easy to install in tight spaces in industrial equipment. It is also maintenance-free, requiring minimal servicing or repairs, thus reducing downtime and maintenance costs. Additionally, the motors' unique design and control algorithms ensure they consume minimal power, making them environmentally friendly and cost-effective.The spokesperson added, "Our stepper motors are intelligently designed to meet the demanding needs of industrial automation. They are engineered to operate seamlessly in harsh environments with high temperatures, vibrations, and extreme pressure. Our customers can trust us to provide them with reliable, high-quality motors that deliver superior performance."The company's state-of-the-art manufacturing facilities use the latest technologies and equipment to ensure efficient production. All the motors undergo rigorous testing and quality control procedures to ensure they meet the highest industry standards. The factories follow strict safety protocols, ensuring the safety of all employees and environmental sustainability.The stepper motor's advanced technology has already found widespread use in industries such as medical devices, printing, textiles, robotics, and aerospace, among others. With the growing emphasis and demand for automation in manufacturing, the demand for this advanced stepper motor technology is expected to continue to increase significantly.In conclusion, advances in automation and industrial technology are expected to continue transforming the manufacturing industry. Stepper Motor Supplier's new technology is poised to play a significant role in driving this transformation, helping companies to increase production efficiency, improve quality, and reduce costs.