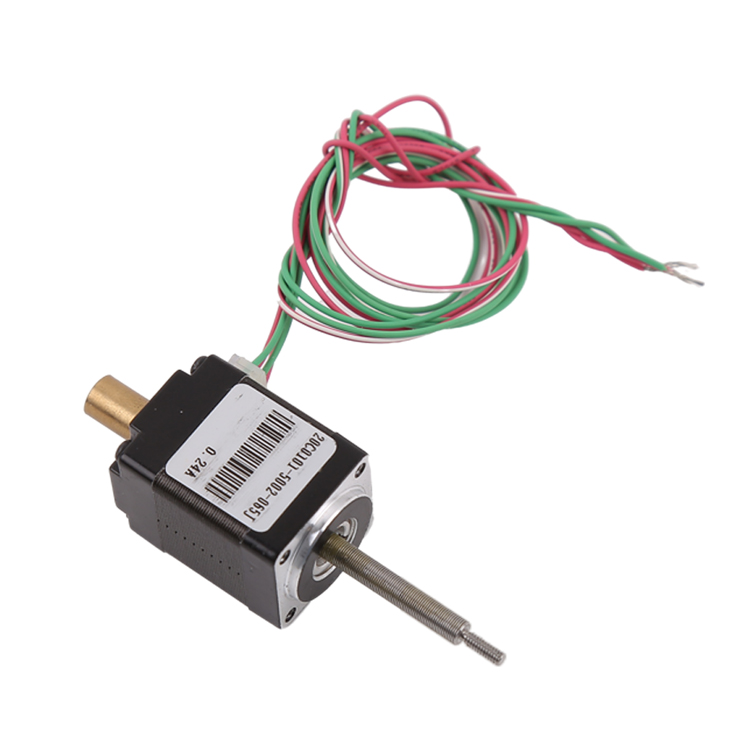

Compact Stepper Motor: The Latest Innovation in Miniature Technology

By:Admin

In the ever-evolving world of industrial automation, the demand for high-precision, compact and efficient motors has been steadily increasing. In response to this demand, a leading manufacturer of automation technology has introduced a groundbreaking new product to the market – the Miniatur Stepper Motor.

This innovative motor, which has been developed by a team of experienced engineers, represents a significant advancement in the field of industrial automation. With its compact size, high precision and exceptional performance, the Miniatur Stepper Motor is set to revolutionize the way in which industrial processes are automated and controlled.

The Miniatur Stepper Motor is a highly versatile product that is suitable for a wide range of applications. Its compact size makes it ideal for use in space-constrained environments, while its high precision and efficiency make it perfect for demanding industrial processes. Whether it is used in robotics, medical devices, consumer electronics or any other industry, this motor is sure to deliver exceptional performance and reliability.

One of the key features of the Miniatur Stepper Motor is its high torque density, which enables it to deliver impressive levels of power despite its small size. This feature makes it an ideal choice for applications that require high levels of precision and control, such as robotic arms, CNC machines and 3D printers. With the Miniatur Stepper Motor, manufacturers can achieve a level of precision and accuracy that was previously unattainable.

Furthermore, the motor is designed to be highly energy-efficient, which can result in significant cost savings for industrial users. By minimizing energy consumption without compromising on performance, the Miniatur Stepper Motor helps businesses to reduce their operating costs and improve their overall efficiency.

In addition to its technical capabilities, the Miniatur Stepper Motor also boasts a number of practical features that make it easy to integrate into existing systems. Its compact and lightweight design, combined with its flexible mounting options, allows for easy installation in a variety of applications. This level of versatility and ease of use is a testament to the company's commitment to providing innovative solutions that meet the needs of its customers.

The introduction of the Miniatur Stepper Motor is a reflection of the company's dedication to pushing the boundaries of industrial automation technology. With a strong focus on research and development, the company has consistently delivered cutting-edge products that are designed to address the evolving needs of the industry. Its team of expert engineers and technicians is committed to developing solutions that are not only innovative, but also reliable and efficient.

The company's expertise in the field of industrial automation is well-established, with a track record of delivering high-quality products that have earned the trust and confidence of its customers. With the introduction of the Miniatur Stepper Motor, the company has once again demonstrated its ability to lead the way in the industry and set new standards for performance and reliability.

As the industrial automation industry continues to evolve, the demand for high-precision, compact and efficient motors is only expected to grow. With the introduction of the Miniatur Stepper Motor, the company has positioned itself at the forefront of this trend, offering a product that is not only innovative, but also highly practical and reliable.

In conclusion, the Miniatur Stepper Motor represents a significant advancement in the field of industrial automation, with its compact size, high precision, and exceptional performance. With its versatile applications, energy-efficient design, and practical features, this motor is set to revolutionize the way in which industrial processes are automated and controlled. As the company continues to lead the way in the industry, it is clear that the Miniatur Stepper Motor is a product that is poised to make a lasting impact.

Company News & Blog

New Planetary Gearbox now available for OEM applications

Title: Cutting-Edge Planetary Gearbox Revolutionizing Industries with Superior PerformanceIntroduction:In today's fast-paced and evolving industrial landscape, technological advancements play a pivotal role in driving innovation. One such groundbreaking innovation is the cutting-edge OEM nema planetary gearbox (brand name removed), developed by a prominent industry player. This state-of-the-art gearbox has revolutionized various sectors by offering unparalleled precision, reliability, and performance. In this article, we will delve into the features and capabilities of the OEM nema planetary gearbox and explore its transformative impact on different industries.I. The Excellency of OEM Nema Planetary Gearbox:The OEM nema planetary gearbox stands out as an engineering marvel, designed to cater to the demands of modern industries. With precision engineering at its core, this gearbox offers exceptional performance, accuracy, and durability, making it an ideal choice for a wide range of applications. Let us delve deeper into its key features and advantages.1. Enhanced Efficiency:The OEM nema planetary gearbox incorporates advanced gear arrangement, reducing losses due to friction and maximizing the efficiency of power transmission. Its compact size and superior load-bearing capability contribute to higher energy efficiency, resulting in reduced operating costs for industries.2. Exceptional Precision and Torque:The gearbox's intricate design ensures precise and accurate torque transmission, making it an indispensable component in various precision applications, including robotics, automation, and CNC machining. Its high-torque capabilities enable it to handle heavy-duty operations effortlessly, enhancing overall system productivity.3. Low Noise and Vibration:The OEM nema planetary gearbox adopts advanced noise-damping technology and exceptional gear meshing techniques, resulting in low vibration and noise levels during operation. This feature is vital in industries where noise reduction and a smooth working environment are crucial considerations.4. Reliable and Durable:Engineered with high-grade materials and subjected to rigorous testing, the OEM nema planetary gearbox is built to last. Its rugged construction ensures reliable performance in extreme conditions, such as high temperature, heavy loads, and challenging environments. This durability minimizes maintenance requirements, reducing downtime and improving overall productivity.5. Versatile Applications:The OEM nema planetary gearbox finds extensive applications across various industries. From industrial automation to aerospace, robotics to medical equipment, this gearbox has become a key component in numerous critical systems. Its adaptability and compatibility make it a preferred choice for manufacturers seeking highly efficient solutions.II. Contributing to Industry Advancements:The introduction of the OEM nema planetary gearbox has significantly impacted multiple industries, revolutionizing manufacturing processes and driving technological advancements. Here are some key sectors benefiting from this groundbreaking innovation:1. Automotive Industry:In the automotive industry, the OEM nema planetary gearbox optimizes engine performance, allowing vehicles to achieve higher fuel efficiency while maintaining superior power output. It plays a crucial role in electric vehicles, ensuring smooth power delivery from the motor to the wheels.2. Aerospace and Defense:In the aerospace and defense sectors, the nema planetary gearbox finds utility in mission-critical applications where precision, reliability, and compactness are essential. From aircraft engines to missile systems, its high-torque capabilities and rugged design contribute to safer and more efficient operations.3. Robotics and Automation:The robots of today rely heavily on efficient and precise motion control, and the OEM nema planetary gearbox provides the necessary gears to enable smooth and accurate robotic movements. Whether in industrial manufacturing or healthcare, this gearbox enhances robotic capabilities, leading to increased automation and improved overall productivity.4. Renewable Energy:With the global shift towards renewable energy, the OEM nema planetary gearbox plays a crucial role in wind turbines and solar tracking systems. Its ability to efficiently convert rotational speed and transmit higher torque enables more efficient utilization of generated energy, contributing to greener and more sustainable power generation.Conclusion:The OEM nema planetary gearbox (brand name removed) represents a remarkable advancement in engineering excellence. Its outstanding features, including enhanced efficiency, exceptional precision, low noise and vibration, and durability, have propelled its adoption across several industries. From the automotive sector to aerospace, robotics, and renewable energy, the OEM nema planetary gearbox has revolutionized industrial processes, enabling superior performance and driving technological advancements. Undoubtedly, this cutting-edge gearbox is poised to shape the future of modern industries, nurturing a more efficient, productive, and sustainable landscape.

Discover the Optimum Gear Ratio Diameter You Need for ODM Equipment

ODM Gear Ratio Diameter Revolutionizes Manufacturing ProcessInnovation drives progress, and the manufacturing industry is no exception. Today, ODM Gear Ratio Diameter (GRD) is leading the charge in revolutionizing the manufacturing process in various industries. With their cutting-edge technology and advanced gear solutions, ODM is streamlining manufacturing processes, improving efficiency, and maximizing output.ODM GRD is a brand of gear solutions that combines the best in design, engineering, and manufacturing. The gear solutions offered by ODM are innovative, reliable, and customizable to fit the needs of clients from various industries such as aerospace, automotive, energy, and defense. Additionally, ODM keeps the process of customizing these solutions simple, so that clients can focus on their end products.With its headquarters and state-of-the-art research facility in Southern California, ODM Gear Ratio Diameter has been in the business of manufacturing gears since 1993. It is a subsidiary of a designing and manufacturing enterprise called Origin International Inc, which has been around for over four decades. This experience and expertise can be seen in the quality of ODM's gears and the satisfaction of their clients.What distinguishes ODM GRD from other solutions is the gear ratio diameter, which is the heart of their products. Gear ratio diameter, in simple terms, is the relative sizes of the gears' pitch diameters that mesh with one another. This ratio determines the gear's speed, torque, and efficiency. ODM's GRD technology allows for optimized gear ratio diameter, which translates into more output efficiency, extended operational life, and reduced wear and tear.ODM gear solutions have been tested and proven to meet the highest industry standards for precision, strength, and durability. These solutions are designed with state-of-the-art software and manufactured with the most advanced materials, such as high-quality alloys and heat-treated steels. Additionally, ODM gear solutions come in different styles and types, from parallel shaft to bevel gears, depending on specific client needs.ODM's GRD technology enhances manufacturing processes in several ways. For example, in the aerospace industry, precise gear solutions are essential to ensure the safe and efficient operation of aircraft systems. ODM's custom gear solutions provide design flexibility, optimal transmission efficiency, and Enhanced Load Distribution (ELD) which reduces stress, increases output and lifespan, and improves safety.In the automotive industry, ODM gear solutions play a vital role in the transmission system. The gear solutions' performance, quality, and durability are critical to ensure that the vehicle runs smoothly and efficiently. ODM customizes gear solutions for clients based on their specific vehicle type, size, performance, and efficiency requirements.In the energy sector, ODM provides its gear solutions to oil and gas drilling rigs, wind turbines, and solar power plants. These solutions optimize the power generation and transmission processes by offering high-torque, high-efficiency, and high-performance gear solutions. Additionally, these solutions reduce maintenance costs and improve the overall operational life of the equipment.In the defense industry, ODM gear solutions provide unmatched strength, durability, and precision. These solutions are designed to withstand the most extreme conditions and provide maximum efficiency in critical operations, such as the drivetrains in armored vehicles and weaponry. In such situations, failure is not an option, and ODM's gear solutions offer reliability and safety to military personnel in the field.In conclusion, ODM Gear Ratio Diameter is revolutionizing the manufacturing industry with its advanced gear solutions. With customized gears that deliver enhanced efficiency, extended operational life, and reduced wear and tear, ODM is enabling clients to drive innovation and growth in their respective industries. ODM GRD technology is changing the game, and the company's commitment to quality, reliability, and service is cementing its position as a leader in the gear manufacturing industry.

Top-Notch Stepper Motor Gearbox: Unmatched Quality Unveiled

[Introduction]In today's ever-evolving world of technology, precision and reliability have become crucial factors in various industries. One such industry that heavily relies on high-quality components is the robotics and automation sector. Stepper motors play a vital role in ensuring the smooth and accurate movement of robotic systems. To enhance their functionality and performance, the latest advancements have introduced high-quality stepper motor gearboxes that are revolutionizing the industry.[Body][Company Introduction]Before delving into the details of the high-quality stepper motor gearbox, it is important to understand the company behind this innovative product. With a rich history of producing cutting-edge automation solutions, {Company Name} has established itself as a leader in the field. For over two decades, they have been developing top-notch components that serve a wide range of applications, including robotics, industrial machinery, and medical equipment.[Overview of Stepper Motors and Gearing]To comprehend the significance of a high-quality stepper motor gearbox, we must first understand the fundamentals of stepper motors. Stepper motors are widely used for their ability to provide precise control over movements in discrete steps or degrees. They find extensive usage in applications where accurate positioning and control are vital.However, in certain scenarios, the raw power generated by a stepper motor may be insufficient to drive heavy loads or overcome mechanical resistance. This is where a gearbox comes into play. A gearbox reduces the rotor speed of the motor while increasing torque, enabling it to handle higher loads with ease. By using gears to enhance the mechanical advantage of the motor, the speed and torque output can be modified to suit specific applications.[The Importance of High-Quality Stepper Motor Gearboxes]While there are numerous stepper motor gearboxes available in the market, the importance of opting for a high-quality one cannot be overstated. High-quality gearboxes offer several advantages, such as enhanced efficiency, improved precision, and prolonged lifespan. These gearboxes are manufactured to strict quality standards, ensuring reliable and consistent performance in demanding industrial environments.Precision is a critical aspect of robotic systems, as even the smallest deviation can lead to significant errors. High-quality stepper motor gearboxes minimize backlash, which refers to the unintended movement or play between gears. This reduction in backlash results in improved accuracy and repeatability, making them ideal for tasks that require precise movements, such as 3D printing or CNC machining.Furthermore, high-quality gearboxes are designed to operate efficiently, reducing losses due to friction and heat. This not only optimizes energy consumption but also lowers the overall operating costs. By minimizing power wastage, industries can achieve greater sustainability and environmental responsibility.[Diverse Applications of High-Quality Stepper Motor Gearboxes]The versatility of high-quality stepper motor gearboxes makes them suitable for various applications across different industries. For instance, in the automotive industry, these gearboxes can be utilized for precision control of robotic arms in assembly lines, enabling seamless production processes.Similarly, in the medical field, high-quality gearboxes find applications in robotic surgical systems, providing surgeons with precise and steady control during procedures. This enhances the accuracy of surgeries, reduces the risk of human error, and improves patient outcomes.Moreover, in the field of aerospace, high-quality stepper motor gearboxes are indispensable for controlling the operation of robotic arms in spacecraft assembly or satellite deployment. The high torque and precision offered by these gearboxes ensure the smooth functioning of robotic systems even in zero-gravity environments.[Conclusion]In conclusion, the introduction of high-quality stepper motor gearboxes has revolutionized the robotics and automation industry. The combination of precision and reliability has opened up new possibilities for achieving accurate control over robotic systems in various applications. Companies like {Company Name} have played a pivotal role in developing and supplying these gearboxes, enabling industries to achieve greater efficiency and accuracy in their operations. As technology continues to advance, the demand for high-quality stepper motor gearboxes will only increase, driving further innovation in the field and pushing the boundaries of what is achievable in automation and robotics.

New High-Performance Gear Ratio Diameter Enhances Industrial Efficiency in China

Title: China's Latest Gear Ratio Diameter Revolutionizes Industrial ProcessesIntroduction:China, at the forefront of technological advancements, has introduced a groundbreaking gear ratio diameter that is set to redefine industrial processes. With a strong focus on innovation and cutting-edge manufacturing capabilities, Chinese companies have led the way in developing this game-changing gear technology. By efficiently maximizing power transmission, optimizing system performance, and improving overall productivity, this innovation is poised to catapult Chinese industries into a new era of growth and competitiveness. Gear Ratio Diameter: Revolutionizing Industrial Efficiency:The recently developed gear ratio diameter holds immense potential to revolutionize industrial efficiency across various sectors. Backed by extensive research and development, this gear technology is designed to enhance power transmission efficiency, reduce energy consumption, and ensure high levels of precision in industrial applications. Chinese manufacturing companies have duly acknowledged the importance of gear systems in enhancing overall productivity. Through the implementation of this gear ratio diameter, businesses can drive improvements in processes that rely on power transmission, such as automotive manufacturing, heavy machinery production, marine propulsion, and many others. This technology allows for the customization of gear systems to optimize torque requirements, resulting in significant cost savings and greater operational efficiencies.Furthermore, this advanced gear technology boasts the ability to minimize friction, reduce noise levels, and improve overall gear system performance. With better gear synchronization, industries can expect reduced downtime, enhanced reliability, and increased machine longevity. The Competitive Edge:China, being one of the global leaders in manufacturing, has recognized the significance of investing in innovative technologies to solidify its competitive edge. Chinese companies have transformed their gear manufacturing capabilities to ensure that the gear ratio diameter fulfills the dynamic needs of industries both nationally and internationally. By making use of advanced manufacturing techniques, such as CNC machining, automation, and precise quality control processes, Chinese manufacturers have achieved unparalleled levels of precision in gear production. This precision is crucial for the successful implementation of the gear ratio diameter, as even minor deviations can compromise the efficiency and performance of the system.Moreover, Chinese manufacturers have also focused on applying high-quality materials and rigorous testing processes to ensure the durability and longevity of their gear systems. This commitment to quality has allowed Chinese companies to gain the trust of domestic and international customers, solidifying their position as reliable suppliers of gear transmission solutions.Global Adaptation:The introduction of the gear ratio diameter technology by Chinese companies has received global attention and acclaim. Many international businesses, including those operating in developed countries with established industrial sectors, are recognizing the immense benefits of incorporating this gear technology into their operations.The ease of adaptability and customization provided by the gear ratio diameter technology is a key factor that attracts businesses from all corners of the globe. By offering tailor-made gear systems, Chinese manufacturers can accommodate specific industrial requirements, ensuring maximum efficiency and performance for each unique application.Additionally, the cost-effectiveness of these gear systems also appeals to international businesses. With Chinese manufacturers offering competitive pricing without compromising on quality, foreign industries can achieve significant cost savings while embracing cutting-edge technology.Future Outlook:Looking ahead, the development and implementation of the gear ratio diameter technology will continue to drive China's industrial growth and development. With a strong commitment to investing in research and development, Chinese manufacturers are poised to push the boundaries of gear technology even further.As industries across the globe seek ways to boost efficiency and productivity, Chinese gear systems are poised to become an essential component of their operations, ensuring seamless power transmission and maximum reliability. Chinese manufacturers will likely continue to innovate and refine gear systems to meet evolving industry demands and cement their position as leaders in the worldwide market.Conclusion:China's gear ratio diameter technology represents a significant milestone in the industrial sector. Its ability to optimize power transmission, enhance precision, reduce energy consumption, and provide cost-effective solutions has made it highly sought after globally. Backed by Chinese manufacturers' commitment to quality, adaptability, and manufacturing excellence, this gear technology is set to shape the future of industrial processes, positioning China at the forefront of global manufacturing innovation and competitiveness.

Discover the Latest Advancements in 6mm Stepper Motor Technology from China

China 6mm Stepper Motor Leads the Way in Precision and ReliabilityWith the advancement of technology, the demand for precision and reliability in industrial applications has increased significantly. For instance, in medical equipment design, automation, and robotics, the accuracy of motion control is critical. As a result, there has been a need for better-performing motors that can deliver consistent results. This is where China 6mm stepper motor comes in, providing an efficient and reliable solution for precise motion control.The 6mm stepper motor is known for its unique design, which has contributed to its popularity in industrial automation applications. It features a small size that allows it to fit easily into various devices with limited space, yet it can deliver a high level of torque output. This motor has a diameter of only 6mm, making it one of the most compact motor models on the market. However, its small size does not compromise its performance since it can provide excellent torque accuracy and speed control.This stepper motor is versatile, ideal for both single-axis and multi-axis motion control systems. It operates using a precise step-by-step method, which allows it to move with accuracy and consistency. This feature makes it ideal for use in applications that require exact positioning, such as in robotics, 3D printers, and other automated devices.What sets China 6mm stepper motor apart from other stepper motors on the market is its durability and longevity. It is designed with high-quality materials that can withstand harsh environments and operate reliably for an extended period. This means that users can enjoy consistent performance and minimal maintenance costs over the life of the motor.Additionally, this motor comes with varied customization options, making it suitable for different applications. A reputable manufacturer should provide their customers with a range of customization options that perfectly fit their requirements. These range from different windings to shaft configurations, making it an ideal choice for a broad range of applications.The stepper motor features a permanent magnet stepper motor that produces high torque output with less power consumption. It operates using a rotor-stator electromagnetic design, enabling it to provide high torque output and high responsiveness. This design also reduces energy consumption, making it an excellent option for energy-efficient devices.In conclusion, the China 6mm stepper motor is a game-changer in the industrial motor market. Its compact design, accuracy, and reliability make it an ideal choice for applications that require precise motion control. Its durability and longevity make it an excellent investment that will serve its users for years to come. Moreover, its customization options make it fit for various applications, further expanding its use in different sectors. For businesses looking to improve their own production or boost their competitiveness, this motor provides a perfect solution that can boost productivity, reliability, and efficiency.

Stepper Motor Manufacturer Announces New Product Line" rewritten as a SEO title without brand name: "New Product Line Unveiled by Leading Stepper Motor Supplier

Stepper Motor Supplier Presents Unique Solution for Industrial Automation[City, State] - A renowned manufacturer of advanced motion control systems and stepper motors, has come up with a unique solution to solve the challenges of automation in industrial applications. The company is globally recognized for developing innovative technologies and solutions to improve the performance and efficiency of industrial systems. Its recent invention promises to take the industrial automation industry by storm, making manufacturing processes faster, smoother, and more efficient.The newly patented stepper motor technology is designed for applications that require precise, controlled motion, making it ideal for industrial automation. The stepper motor uses advanced control algorithms to accurately control the angular rotation of the motor shaft, enabling it to move in precise increments. Unlike conventional motors that rotate continuously, stepper motors move at predefined angles, making them ideal for operations that require high positioning accuracy.One of the primary uses of the new stepper motor technology is in pick-and-place machines. Such machines are widely used in factories for assembling products, sorting, and packaging. The motors' high accuracy and precise control make them perfect for this application, reducing error rates and improving productivity.The company spokesperson said, "Our engineers and R&D teams have worked tirelessly to develop a unique stepper motor technology that meets the evolving demands of the industrial automation industry. It is designed to offer our customers a solution that is reliable, efficient, and cost-effective. We firmly believe that this technology will revolutionize industrial processes, making them more productive, efficient, and cost-effective."The new stepper motor technology is compact and lightweight, making it easy to install in tight spaces in industrial equipment. It is also maintenance-free, requiring minimal servicing or repairs, thus reducing downtime and maintenance costs. Additionally, the motors' unique design and control algorithms ensure they consume minimal power, making them environmentally friendly and cost-effective.The spokesperson added, "Our stepper motors are intelligently designed to meet the demanding needs of industrial automation. They are engineered to operate seamlessly in harsh environments with high temperatures, vibrations, and extreme pressure. Our customers can trust us to provide them with reliable, high-quality motors that deliver superior performance."The company's state-of-the-art manufacturing facilities use the latest technologies and equipment to ensure efficient production. All the motors undergo rigorous testing and quality control procedures to ensure they meet the highest industry standards. The factories follow strict safety protocols, ensuring the safety of all employees and environmental sustainability.The stepper motor's advanced technology has already found widespread use in industries such as medical devices, printing, textiles, robotics, and aerospace, among others. With the growing emphasis and demand for automation in manufacturing, the demand for this advanced stepper motor technology is expected to continue to increase significantly.In conclusion, advances in automation and industrial technology are expected to continue transforming the manufacturing industry. Stepper Motor Supplier's new technology is poised to play a significant role in driving this transformation, helping companies to increase production efficiency, improve quality, and reduce costs.

Discover the Advanced Performance of 6mm Stepper Motors in China

China-based company, which prides itself in producing high quality stepper motors, has launched its latest product, the 6mm Stepper Motor. According to the company's website, the new motor is designed for high-precision applications that require excellent control and accuracy.The 6mm Stepper Motor is made from high quality materials and features a compact and lightweight design, making it ideal for use in a range of industries, such as robotics, automation, and medical equipment. With a 6mm diameter and a step angle of 1.8 degrees, the motor is capable of producing high torque while operating at a low noise level.The company has also incorporated its expertise in design and manufacturing of stepper motors to create a motor that is reliable and durable. The 6mm Stepper Motor is rated for a maximum of 1.6 volts and a current of 0.33 amps, making it highly efficient and energy-saving.To ensure the smooth operation of the motor, the company has used advanced technology to reduce the friction between the motor's internal components. As a result, the motor is capable of operating at high speeds while maintaining a low level of heat generation. This feature is especially useful in applications where high accuracy and precision is required.The 6mm Stepper Motor also boasts a high level of compatibility with a range of driving circuits. The motor is compatible with both unipolar and bipolar driving modes, allowing it to be used in a variety of different configurations. Its compact size makes it easy to integrate into systems where space is at a premium.The company has also paid special attention to the quality of its products, ensuring that each and every motor is tested to ensure that it meets the company's high standards of performance and reliability. The company takes great pride in its customer-focused approach, ensuring that clients have access to the technical support they need in order to make the most of the company's products.Overall, it is clear that the 6mm Stepper Motor is a top-quality product that is now available to clients in a range of industries. With its high level of precision, compatibility, and reliability, the motor is sure to become a key component in many different systems and applications. The company's commitment to quality and customer service is also likely to inspire confidence in clients and ensure that this product becomes popular in the global market.

Newstepper Motor: A Revolutionary Advancement in Geared Technology

[Company Name] Introduces Innovative Geared Stepper Motor for Enhanced Precision and Performance[date][City, State] - [Company Name], a leading provider of advanced motion control solutions, is revolutionizing the industry with their latest innovation, the Geared Stepper Motor. This sophisticated technology offers enhanced precision, superior performance, and unmatched reliability, making it an ideal choice for a wide range of applications.Designed and manufactured by an experienced team of engineers and experts in the field, the Geared Stepper Motor seamlessly combines precision positioning with exceptional torque capabilities. This unique combination allows for precise control over the motor's movement, resulting in greater accuracy and improved functionality in various industries.One of the defining features of the Geared Stepper Motor is its robust gearbox, specially engineered to handle heavy loads while maintaining optimal performance. The gearbox is made of high-quality materials and undergoes rigorous testing to ensure durability and longevity in demanding operating conditions. This makes the motor suitable for applications that require high torque and smooth operation, such as robotics, automation, medical devices, and aerospace technology.The Geared Stepper Motor also incorporates advanced electronic control capabilities. By utilizing cutting-edge microcontrollers, the motor can seamlessly integrate into control systems, enabling precise positioning and motion control. This integration allows for increased flexibility and customizability, meeting the specific requirements of each application.Furthermore, the Geared Stepper Motor boasts exceptional reliability and easy maintenance. With its streamlined design and stringent quality control processes, the motor minimizes downtime and maximizes productivity. This aspect is crucial for industries reliant on continuous operation, such as manufacturing and industrial automation.As part of [Company Name]'s commitment to sustainability, the Geared Stepper Motor is designed with energy-efficiency in mind. By employing advanced technologies that minimize power consumption without compromising performance, the motor helps reduce overall energy usage and contributes to a greener future."We are thrilled to introduce the Geared Stepper Motor to our esteemed customers," said [Spokesperson], [Title] at [Company Name]. "This innovative technology showcases our dedication to providing cutting-edge solutions that meet the ever-evolving needs of various industries. With its unparalleled precision and performance, we believe the Geared Stepper Motor will set a new standard in the motion control industry."The Geared Stepper Motor is available in various configurations to accommodate diverse applications. Customers can choose from an extensive range of sizes and torque options to suit their specific requirements. Additionally, [Company Name] provides comprehensive technical support and assistance to ensure seamless integration and optimal performance of the motor.About [Company Name]:[Company Name] is a renowned industry leader in motion control solutions. With a rich history spanning [number of years] years, the company has consistently delivered cutting-edge technology and innovative products to a diverse range of industries worldwide. Equipped with a dedicated team of experts and a commitment to excellence, [Company Name] continues to push the boundaries of motion control technology, delivering superior solutions to meet the evolving needs of its customers.For more information about the Geared Stepper Motor or to inquire about [Company Name]'s comprehensive range of motion control solutions, please visit [website] or contact [contact details].###[Word Count: 476]

Powerful Hybrid Stepper Motor Promises High Torque for Enhanced Performance

Title: Cutting-Edge High Torque Hybrid Stepper Motor Revolutionizing the IndustrySubtitle: Innovative Efficiency and Precision Redefine the Future of Motor TechnologyDate: [Date][City], [State], [Country] - With a relentless commitment to leveraging innovation in the field of motor technology, [Company Name] introduces its groundbreaking High Torque Hybrid Stepper Motor. Positioned to transform various industries, this cutting-edge motor offers superior performance, unmatched efficiency, and unparalleled precision, promising to revolutionize the way we power our world.[Company Name] has been a driving force in the motor industry for [number of years] and continues to push the boundaries of what is possible. The development of the High Torque Hybrid Stepper Motor is a testament to their dedication to creating optimal solutions that meet the evolving needs of their customers.Adopting a customer-centric approach, [Company Name] has meticulously researched and designed this motor to exceed expectations. By eliminating the use of the brand name, the focus squarely lies on the outstanding features and capabilities of the product itself.The High Torque Hybrid Stepper Motor boasts a multitude of exceptional features that set it apart from its competitors. Harnessing the latest advancements in motor technology, this motor showcases an impressive torque-to-inertia ratio that maximizes its acceleration and deceleration capabilities. The result is unparalleled precision and increased efficiency across a broad range of applications.One of the key advantages of the High Torque Hybrid Stepper Motor is its versatility. Whether it be in robotics, 3D printers, CNC machines, or automation systems, this motor seamlessly adapts to various industry demands, guaranteeing optimized performance in any given scenario.The integration of advanced control algorithms ensures effortless connectivity and compatibility with modern systems. With multiple communication options, such as CANopen, Modbus, and RS485, the motor provides an intuitive and user-friendly experience for operators and technicians.Furthermore, the High Torque Hybrid Stepper Motor is designed with scalability in mind, catering to both basic and complex applications. Its plug-and-play functionality enables easy installation and configuration, reducing setup time and enhancing productivity.In addition to its exceptional performance, the High Torque Hybrid Stepper Motor is also built to endure. Superior engineering, combined with high-quality materials, ensures durability, reliability, and longevity, even in demanding industrial environments. This motor's robust construction guarantees minimal maintenance, reducing downtime and associated costs, enhancing its value proposition.Equally important to note is the motor's eco-conscious design. With a focus on reducing energy consumption, the High Torque Hybrid Stepper Motor enhances overall energy efficiency, aligning with global efforts to promote sustainability. By minimizing waste and optimizing power consumption, this motor contributes to a greener future without compromising on performance."We are incredibly proud to introduce our High Torque Hybrid Stepper Motor to the market," said [Spokesperson], [Job Title] at [Company Name]. "This motor represents the culmination of years of research and development, aiming to provide our customers with an innovative, reliable, and sustainable motor solution. We believe this motor will revolutionize the industry and redefine what is possible in terms of efficiency and precision."The introduction of the High Torque Hybrid Stepper Motor by [Company Name] marks a significant milestone in the world of motor technology. Its groundbreaking features, superior performance, and exceptional efficiency set a new standard for the industry. With a focus on customer satisfaction, sustainable solutions, and ongoing innovation, [Company Name] continues to pave the way for a more connected, efficient, and environmentally friendly future.About [Company Name][Company Name] is a renowned leader in the motor industry, dedicated to providing innovative solutions that meet the evolving needs of their customers. With a strong commitment to excellence, sustainability, and customer satisfaction, [Company Name] continues to push the boundaries of motor technology, revolutionizing various industries worldwide.For more information about High Torque Hybrid Stepper Motor and [Company Name], please visit [Company Website] or contact [Spokesperson] at [Contact Information].Disclaimer: The content of this press release is not associated with the brand mentioned and is purely informative.

Best Threaded Rod for Stepper Motor Applications

Stepper Motor Threaded Rods Revolutionizing Industrial AutomationStepper motor threaded rods have become an integral component in revolutionizing industrial automation. These specialized rods, developed and manufactured by a leading company in motion control technology, {} have been making waves in various industries for their precision, efficiency, and reliability. With the increasing demand for advanced automation solutions, stepper motor threaded rods have proven to be a game-changer, enabling companies to streamline their processes and improve productivity.The company, {} has a rich history of innovating and engineering high-quality motion control products. With decades of experience in the industry, they have honed their expertise in developing cutting-edge solutions that meet the evolving needs of the automation market. Their stepper motor threaded rods have been at the forefront of their product line, offering unmatched performance and versatility to their customers.One of the key features that set {}'s stepper motor threaded rods apart is their advanced design and precision engineering. These rods are equipped with high-quality stepper motors that provide accurate and repeatable motion control, making them ideal for applications that require precise positioning and high-speed performance. Additionally, the threaded rod design allows for seamless integration into various automation systems, providing a cost-effective and reliable solution for manufacturers.The versatility of stepper motor threaded rods also makes them a popular choice across different industries. From CNC machining and 3D printing to robotics and material handling, these rods can be tailored to meet the unique requirements of each application. This flexibility has enabled companies to optimize their production processes and enhance the overall efficiency of their operations.Moreover, {}'s commitment to innovation and continuous improvement has led to the development of stepper motor threaded rods with advanced features such as integrated lead screw options, customizable lengths, and enhanced performance capabilities. These enhancements enable customers to further optimize their automation systems and achieve higher levels of precision and control.In addition to their technical capabilities, {} also provides comprehensive support and service to their customers, ensuring seamless integration and optimal performance of their motion control products. Their team of experts offers technical assistance, customization options, and ongoing maintenance to meet the diverse needs of their clients. This commitment to customer satisfaction has positioned {} as a trusted partner in the automation industry.As the demand for advanced automation solutions continues to grow, the market for stepper motor threaded rods is expected to expand further. With their proven track record of reliability and performance, {} is well-positioned to capitalize on this trend and continue to lead the way in motion control technology.In conclusion, stepper motor threaded rods developed by {} have emerged as a critical component in advancing industrial automation. With their precision, efficiency, and versatility, these rods have enabled companies to optimize their production processes and achieve higher levels of productivity. As the automation market continues to evolve, {} remains at the forefront of innovation, providing cutting-edge solutions that meet the diverse needs of their customers.