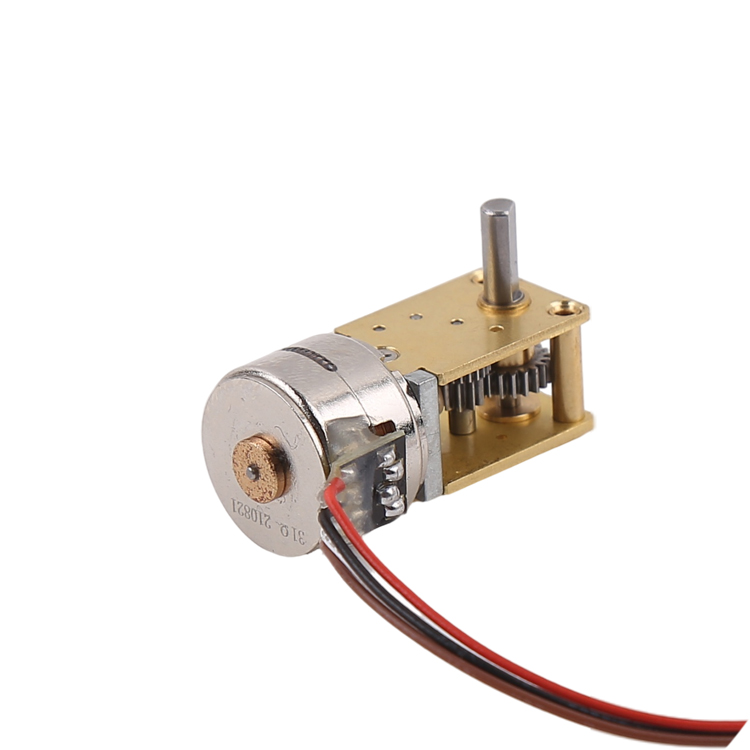

| Model No. | SM15-818G |

| Motor diameter | 15mm |

| Motor type | Permanent magnet motor |

| Drive voltage | 5V DC |

| Coil resistance | 31Ω±10%/phase |

| Number of phase | 2 phases |

| Step angle | 18° |

| Gear ratio | 21:1~1030:1 |

| OEM&ODM SERVICE | AVAILABLE |

| EFFICIENCY | 22%-27% |

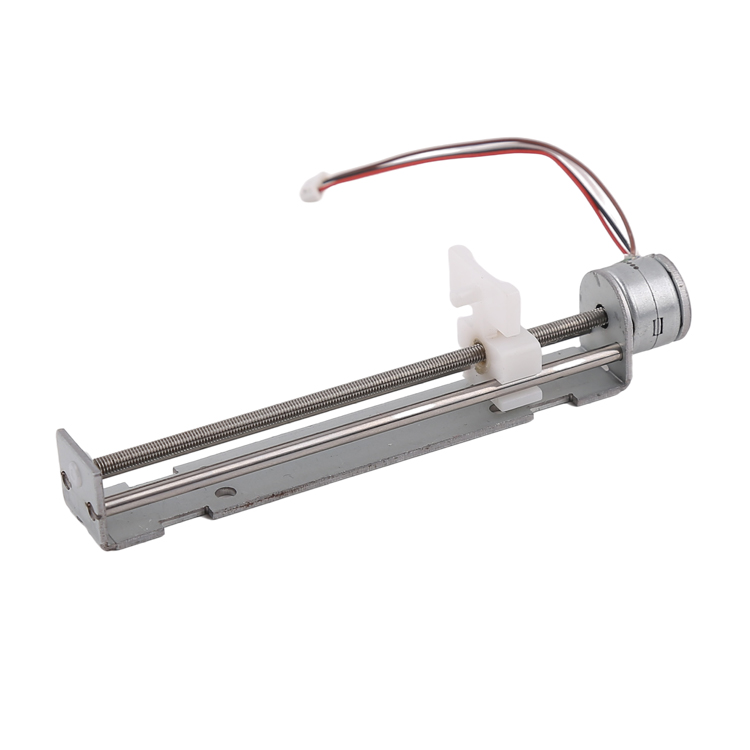

The gear box has high precision, high efficiency and low noise, which makes the product have good reliability. The power input position of the stepper motor can be in the form of FPC, FFC, PCB cable, etc. The output shaft of the motor can adopt various output structures, such as circular shaft, D-shaft and wire bar. Geared stepper motors, widely used in Smart home, personal care, home appliance equipment, smart medical equipment, smart robot, smart logistics, smart cars, communication equipment, smart wearable devices, consumer electronics, camera equipment, and other industries.Lead time for samples: Standard motors in stock: within 3 days Standard motors not in stock: within 15 days Customized products: About 25~30 days (based on complexity of customization) Lead time for building a new mold: generally about 45 days Lead time for mass production: based on order quantity Packaging: Samples are packed in foam sponge with a paper box, shipped by express Mass production, motors are packed in corrugated cartons with transparent film outside. (shipping by air) If shipped by sea, product will be packed on pallets

The gear box has high precision, high efficiency and low noise, which makes the product have good reliability. The power input position of the stepper motor can be in the form of FPC, FFC, PCB cable, etc. The output shaft of the motor can adopt various output structures, such as circular shaft, D-shaft and wire bar. Geared stepper motors, widely used in Smart home, personal care, home appliance equipment, smart medical equipment, smart robot, smart logistics, smart cars, communication equipment, smart wearable devices, consumer electronics, camera equipment, and other industries.Lead time for samples: Standard motors in stock: within 3 days Standard motors not in stock: within 15 days Customized products: About 25~30 days (based on complexity of customization) Lead time for building a new mold: generally about 45 days Lead time for mass production: based on order quantity Packaging: Samples are packed in foam sponge with a paper box, shipped by express Mass production, motors are packed in corrugated cartons with transparent film outside. (shipping by air) If shipped by sea, product will be packed on pallets On samples and air shipping, we use Fedex/TNT/UPS/DHL. (5~12 days for express service) For sea shipping, we use our shipping agent, and ship from Shanghai port. (45~70 days for sea shipping)1.Are you a manufacturer? Yes, we are a manufacture, and we produces mainly stepper motors. 2.Where is your factory location? Can we visit your factory? Our factory is located in Changzhou, Jiangsu. Yes, you are very welcome to visit us. 3.Can you provide free samples? No, we don’t provide free samples. Customers won’t treat free samples fairly. 4.Who pays for shipping cost? Can I use my shipping account? Customers pay for shipping cost. We will quote you shipping cost. If you think you have cheaper/more convenient shipping method, we can use you shipping account. 5.What’s you MOQ? Can I order one motor? We don’t have MOQ, and you can order only one piece sample. But we recommend you to order a little bit more, just in case the motor is damaged during your testing, and you can have a back-up. 6.We are developing a new project, do you provide customization service? Can we sign a NDA contract? We have over 20 years of experience in stepper motor industry. We have developed many projects, we can provide full set customization from design drawing to production. We are confident we can give you few advice/suggestions for your stepper motor project. If you are worrying about confidential issues, yes, we can sign a NDA contract. 7.Do you sell drivers? Do you produce them? Yes, we do sell drivers. They are only suitable for temporary sample test, not suitable for mass production. We do not produce drivers, we only produce stepper motors

On samples and air shipping, we use Fedex/TNT/UPS/DHL. (5~12 days for express service) For sea shipping, we use our shipping agent, and ship from Shanghai port. (45~70 days for sea shipping)1.Are you a manufacturer? Yes, we are a manufacture, and we produces mainly stepper motors. 2.Where is your factory location? Can we visit your factory? Our factory is located in Changzhou, Jiangsu. Yes, you are very welcome to visit us. 3.Can you provide free samples? No, we don’t provide free samples. Customers won’t treat free samples fairly. 4.Who pays for shipping cost? Can I use my shipping account? Customers pay for shipping cost. We will quote you shipping cost. If you think you have cheaper/more convenient shipping method, we can use you shipping account. 5.What’s you MOQ? Can I order one motor? We don’t have MOQ, and you can order only one piece sample. But we recommend you to order a little bit more, just in case the motor is damaged during your testing, and you can have a back-up. 6.We are developing a new project, do you provide customization service? Can we sign a NDA contract? We have over 20 years of experience in stepper motor industry. We have developed many projects, we can provide full set customization from design drawing to production. We are confident we can give you few advice/suggestions for your stepper motor project. If you are worrying about confidential issues, yes, we can sign a NDA contract. 7.Do you sell drivers? Do you produce them? Yes, we do sell drivers. They are only suitable for temporary sample test, not suitable for mass production. We do not produce drivers, we only produce stepper motors 1. worm gearboxes are inefficient (less than 30%) and will have lower output torque than other types of gearboxes. 2. Worm gearboxes have a self-locking function, which will automatically lock when the motor is powered off. 3. It can also be used with 15mm dual stepper motors, N20 motors, 10mm stepper motors and 20mm stepper motors, which customers can choose according to their needs. As shown in the figure below: 15mm double stepper motor + worm gearbox

1. worm gearboxes are inefficient (less than 30%) and will have lower output torque than other types of gearboxes. 2. Worm gearboxes have a self-locking function, which will automatically lock when the motor is powered off. 3. It can also be used with 15mm dual stepper motors, N20 motors, 10mm stepper motors and 20mm stepper motors, which customers can choose according to their needs. As shown in the figure below: 15mm double stepper motor + worm gearbox | Gear ratio | 21:1 | 42:1 | 118:1 | 236:1 | 302:1 | 399:1 | 515:1 | 603:1 | 798:1 | 1030:1 |

| Precise ratio | 21.00 | 42.00 | 118.067 | 236.133 | 301.726 | 398.976 | 515.200 | 603.452 | 797.853 | 1030.400 |

| Worm gear starts No. | 2 | 1 | 2 | 1 | 2 | 2 | 2 | 1 | 1 | 1 |

| Gear levels | 3 | 3 | 4 | 4 | 5 | 5 | 5 | 5 | 5 | 5 |

| Efficiency | 27% | 27% | 24% | 24% | 22% | 22% | 22% | 22% | 22% | 22% |

N20 DC motor + worm gear box

10mm stepper motor + worm gear box

20mm stepper motor + worm gear box